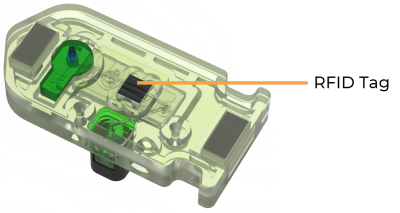

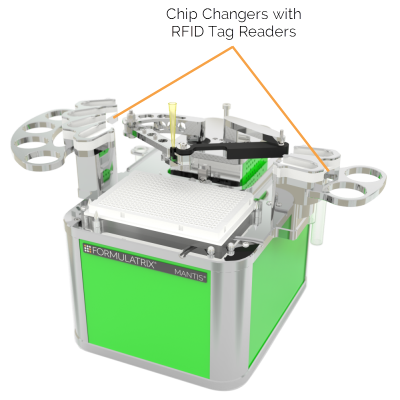

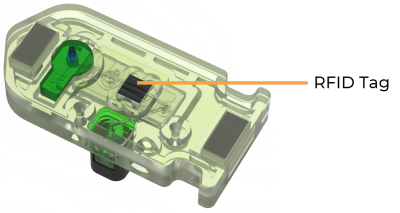

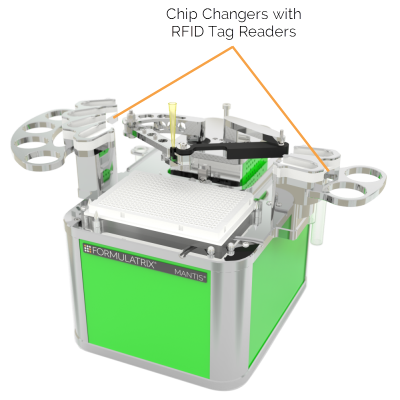

This MANTIS option uses a Radio-Frequency Identification (RFID) tag installed in each chip to provide helpful information about the chip usage and dispense process. The MANTIS instrument with RFID is fitted with six antennas for a faster RFID tag reading/writing process.

|

|

| MANTIS Chip With an RFID Tag | MANTIS RFID |

|

| LC3 Carousel with RFID Reader |

The following basic information is stored on each RFID chip itself:

| Option | Description |

|---|---|

| Chip Type | E.g. High Volume, Low Volume, PFE, 3PFE, or Continuous Flow. |

| Total Volume Dispensed | Total volume that this chip has dispensed to date. |

| Small Diaphragm Cycle | Total number of Small Diaphragm cycles to date. |

| Large Diaphragm Cycle | Total number of Large Diaphragm cycles to date. |

| Date of Manufacture | This chip’s manufacturing date. |

| Chip Serial Number | This chip's unique ID. |

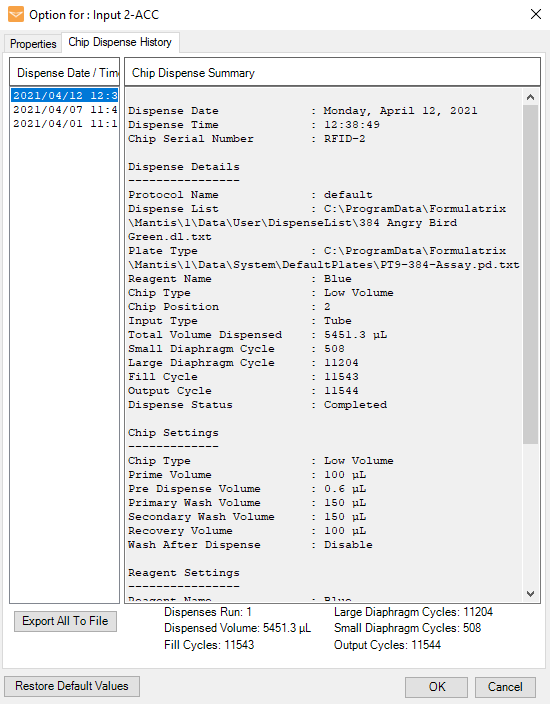

Dispense History

After each dispense using an RFID chip, the following information will be stored directly onto your MANTIS database, tagged to the serial number of that chip.

| Option | Description |

|---|---|

| Dispense Date | Dispensing process date. |

| Protocol Name | Name of the protocol used for the dispensing process. |

| Dispense List Name | Name of the dispense list used for the dispensing process. |

| Plate Type | Plate type used for the dispensing process. |

| Reagent Name | Name of the reagent used during the dispensing process. |

| Chip Position Number | Chip station number in the Chip Changer or LC3 Carousel. |

| Input Type | Input source type, such as tube or pipette. |

| Total Volume Dispensed | Total volume that this chip has dispensed to date. |

| Small Diaphragm Cycle | Total number of Small Diaphragm cycles to date. |

| Large Diaphragm Cycle | Total number of Large Diaphragm cycles to date. |

| Fill Cycle | Total number of Fill Diaphragm cycles to date. |

| Output Cycle | Total number of Output Diaphragm cycles to date. |

| Dispense Status | Status of a dispensing process, whether it is finished or interrupted. |

| Prime Volume | Volume used for the priming process. |

| Pre-Dispense Volume | Volume used for the pre-dispensing process. |

| Primary Wash Volume | Volume used for the primary wash process. |

| Secondary Wash Volume | Volume used for the secondary wash process. |

| Recovery Volume | Volume used for the recovery process. |

| Wash After Dispense |

Wash behavior after the dispensing process. There are three kinds of behaviors:

|

| Chip Pressure | Chip pressure value. |

| Bottle Pressure | Bottle pressure value. |

| Chip Vacuum | Chip vacuum value. |

| Wash Pressure | Wash pressure value. |

| Wash Vacuum | Wash vacuum value. |

| Prime Pressure | Prime pressure value |

| Recovery Pressure | Recovery pressure value. |

| Recovery Vacuum | Recovery vacuum value. |

|

|

| MAOWH-V48R824 |