The MANTIS Molecular Grade (MG) Chip Cleaning Procedure was created to assist MANTIS users in sterilizing MANTIS chips to a molecular grade standard. It ensures that the chips are free from DNA, RNA, RNase, DNase, proteases, and microbial contamination. This procedure is intended to be used only as a guide, and all local cleaning protocols should be certified by the appropriate laboratory personnel.

This protocol has demonstrated the sterility grade of chips to the levels described in the Certifications section.

Chip exposure to any object that is not MG grade or cleaned to MG grade poses risk of contamination.

We strongly recommend that all operations are monitored by authorized operators and personnel are instructed on the importance of avoiding RNase, DNase, and proteases contamination.

MANTIS MG chips were originally cleaned and packaged in an isolated, MG-grade clean environment. All surfaces and objects must be wiped with a cleaning solution before coming in contact with MG chips.

Wear gloves at all times during the cleaning process. Contact with bare hands will result in contaminating the chips with the aforementioned biological contaminants.

![]() 0.1 N NaOH wash solution has a pH of 13 and is highly corrosive. Handle with care to prevent injury.

0.1 N NaOH wash solution has a pH of 13 and is highly corrosive. Handle with care to prevent injury.

The standard cleaning procedure of the MG chips should follow the steps below.

Prepare a clean working environment (e.g. Bio Safety Cabinet, clean room, or laminar airflow cabinet) by wiping all working surfaces with a 0.5% hypochlorite solution or suitable disinfectant.

Preclean the required materials by wiping them before use with the hypochlorite/cleaning solution to prevent cross-contamination among the materials.

Proceed to the cleaning process by choosing the following options:

Prewash the chips by running a standard wash, such as 70% alcohol and water, using the built-in MANTIS wash stations to remove large debris and pre-clean the chip.

Using MANTIS, dispense NaOH solution through a chip to fill the diaphragms of the chip. Then, let the solution stay in the chip for at least 5 minutes. Following the soak, dispense the remaining NaOH solution out of the chip and disassemble it by removing the nozzle and tube adapter. Soak all the components of the chip in the NaOH solution for 5 minutes.

Chip components are then rinsed with Molecular Grade (MG) water, and the chip is assembled and returned to the MANTIS. MG water is dispensed through the chip twice to remove residual NaOH.

Put the chip in the sterilised container with proper sealing for storage or use it immediately.

Important: The clean chips should be used immediately or stored in a clean air-tight container to prevent contamination. Cleanliness of chips is dependent upon individual site storage conditions. Rewash the chips before use if there are concerns with the sterility of the storage environment.

Required Materials:

MANTIS instrument and computer

2 pcs of Molecular Grade (MG) pipette tips

3 pcs of 50 mL beakers:

Paper towels

1 pc of Tweezers

Powder-free gloves

Sterilized clean container for storing the chips

Required Solutions:

Prerequisites:

To clean the MG chips:

Prepare the materials and solutions by following the steps below:

Pour ~25 mL NaOH into the NaOH beaker, ~25 mL MG water to each Rinse 1 beaker and Rinse 2 beaker.

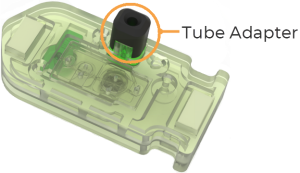

Remove the tube adapter from a MANTIS chip input and attach the chip to the chip changer. For more information, go to Setting Up MANTIS for a Dispense.

Tube Adapter on the MANTIS Chip

Take one pipette tip and manually fill it with the NaoH solution with the following volume:

Attach the pipette tip into the chip input.

Dispense 500 µL of the NaOH if you are using an HV chip or 75 µL of NaOH if using an LV chip.

Note: This can be done via a manual prime to dispense directly into the waste station.

Proceed to step 2 to start the cleaning process.

Activate the chip diaphragms to fill the fluid path with NaOH by following the steps below.

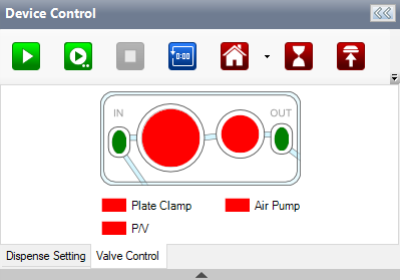

In the MANTIS software, hover over to the Device Control Panel, and click the Valve Control tab. The controls in the Valve Control tab will automatically change when you click on the particular valve, control, or diaphragm.

Valve Control Tab

Click at the Air Pump so that it is open, indicated by turning red to green.

Open the OUT valve by clicking the valve so that the indicator is turned green.

Close both of the chip’s diaphragms by clicking both circles. The closed diaphragms are indicated by red.

Close the OUT valve, so that the indicator is turning to red.

Open the IN valve, so that the indicator is turning to green.

Open both diaphragms by clicking both circles, so that they turn to green.

Wait for the NaOH to soak inside the chip for 5 minutes.

Then, dispense the remaining 500 µL of the NaOH if you are using an HV chip or 75 µL NaOH if you are using an LV chip.

When the dispense is finished, detach the pipette tip and remove the chip from the chip changer.

Disassemble the chip by removing the silicone nozzle. Use the tweezers if needed.

Submerge the chip components (chip, nozzle, and tube adapter) in NaOH beaker, and agitate the bath to ensure all surfaces are in contact with the solution. Soak the chip components for ~5 minutes.

After that, rinse the chip, nozzle, and tube adapter with MG water in Rinse 1 beaker. Make sure that all chip components surfaces come in contact with the rinse solution.

Repeat step 8 to proceed to the 2nd rinse process, using fresh MG water in Rinse 2 beaker.

Reassemble the chip components and attach the chip back to the chip changer. Proceed to rinse the chip’s diaphragm by following the steps below:

Take the second pipette tip and attach it to the chip.

Fill the pipette tip with the MG water with the following volume:

Dispense 1250 µL of MG water if you are using an HV chip or 260 µL of MG water if you are using an LV chip. The dispense volume is more than fill volume to ensure that you completely purge the liquid from the chip.

Repeat steps a-c for the second wash.

Finally, keep the chips in a sterile container or use them immediately.

Note: For long-term storage, flush the chip with MG-grade 30% glycerol solution before storing it to the container to avoid the tendency of the washed valve clusters getting sticky after some months.

Internal testing has shown that this procedure can clean MANTIS’s chips below the following levels of detectable contamination.

Free of any detectable DNAse/RNAse contamination as tested with commercial fluorometric assays.

Free of any detectable DNA contamination (will not inhibit PCR reactions)

Free of any detectable protease contamination

|

|

| MAOWH-V48R824 |