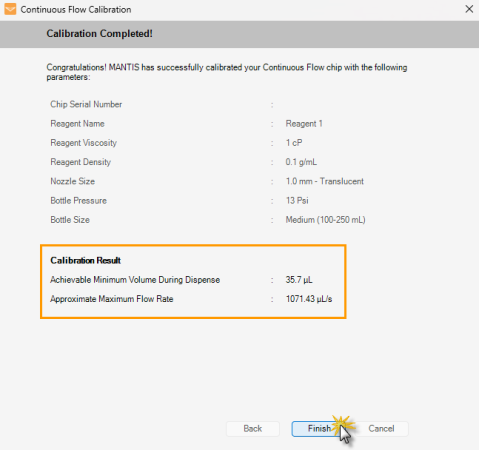

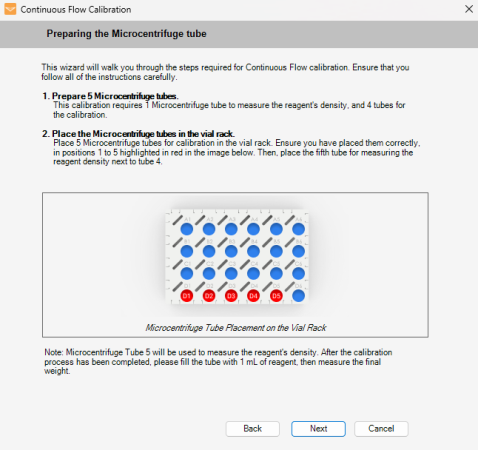

| Microcentrifuge Tubes |

-

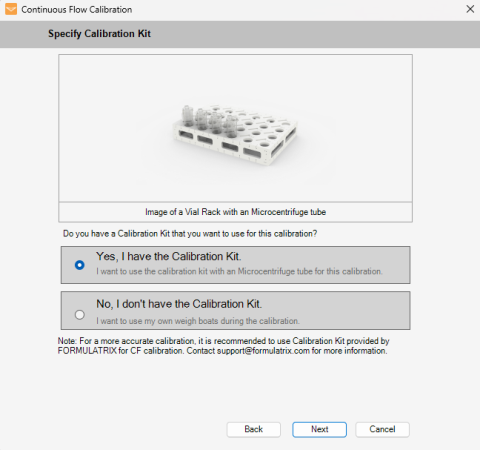

Follow the on-screen instructions to prepare the microcentrifuge tubes on the vial rack.

-

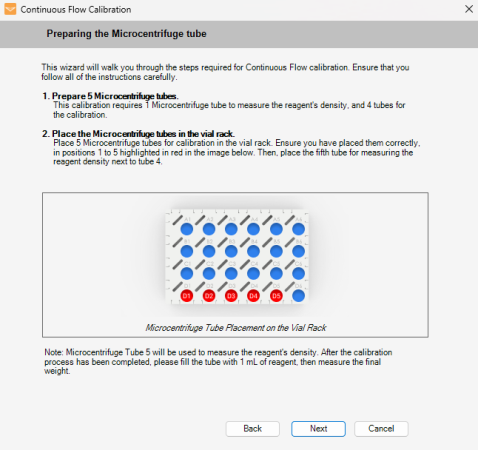

For standard CF chip:

If you have not previously defined the reagent density in the Density field, place an additional microcentrifuge tube in position 5, as shown in the image.

Put the 5 Empty Microcentrifuge Tubes in the Vial Rack

-

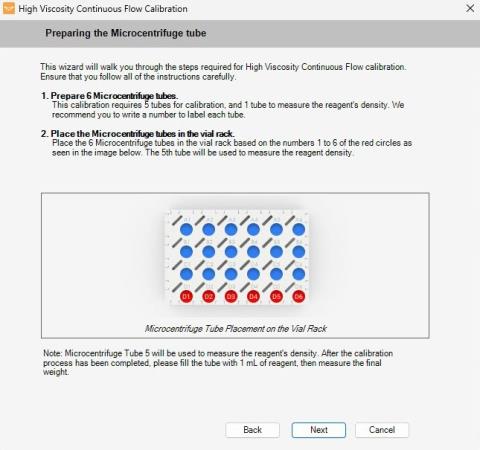

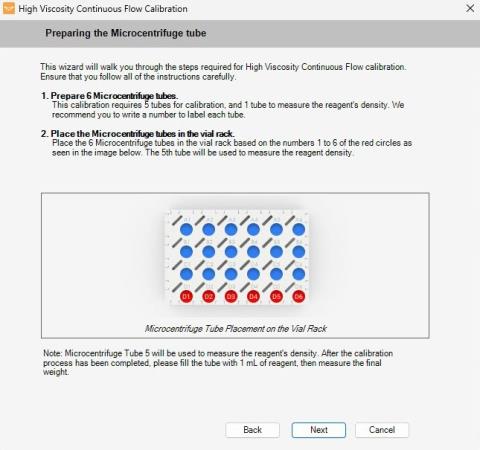

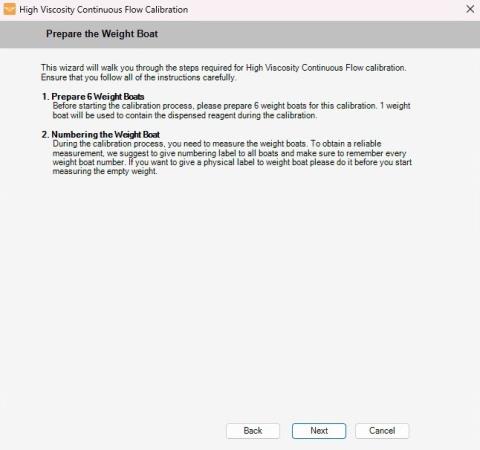

For HVCF chip:

If you have not previously defined the reagent density in the Density field, place an additional microcentrifuge tube in position 5, as shown in the image. The software may also prompt you to place an additional microcentrifuge tube in position 6, if necessary.

Put the 5 and 1 Additional Empty Microcentrifuge Tubes in the Vial Rack

-

Click Next to continue.

-

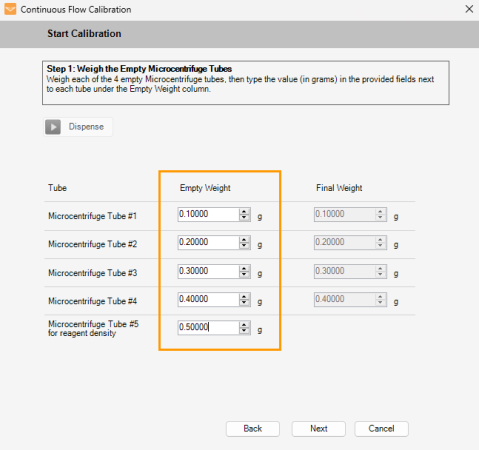

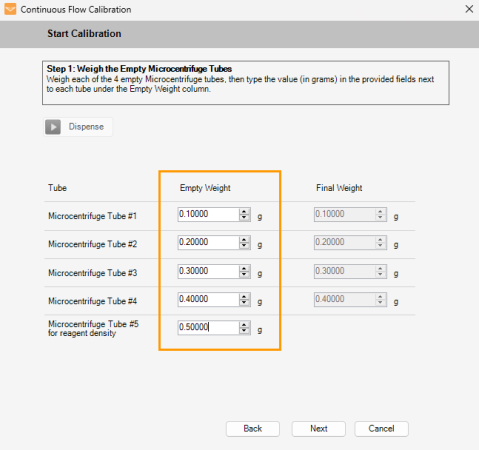

Weigh each empty microcentrifuge tube using a balance. Type the weight value (in grams) of each tube in the Empty Weight column, then click Next.

Type the Weight Value in Each Empty Weight Column

-

Start the calibration:

-

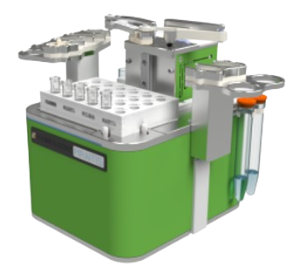

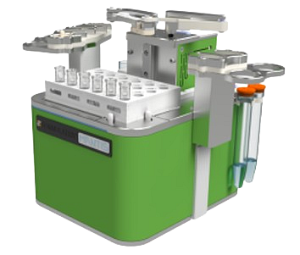

Place the tube rack on the MANTIS deck as seen below. Then, click Next.

|

|

| Vial Rack for CF Chip Calibration

|

Vial Rack for HVCF Chip Calibration

|

-

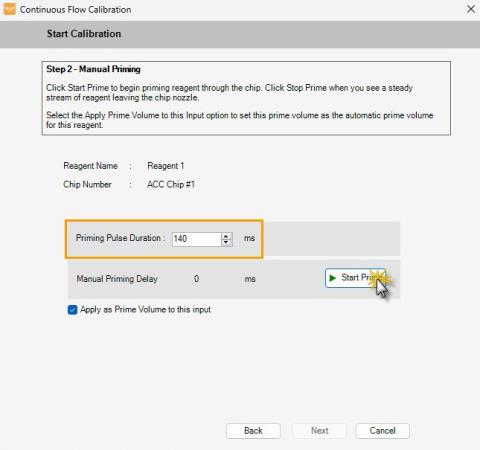

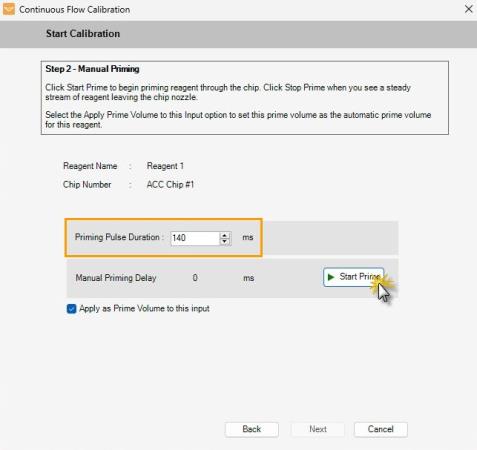

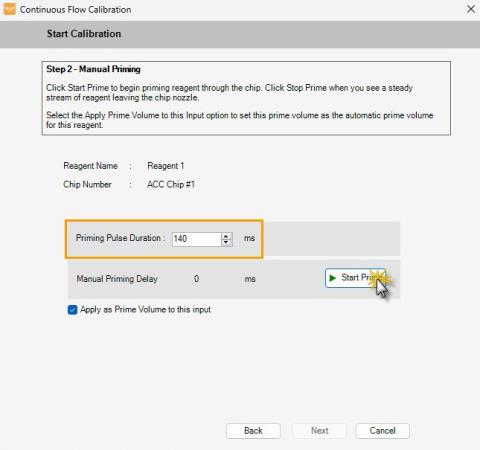

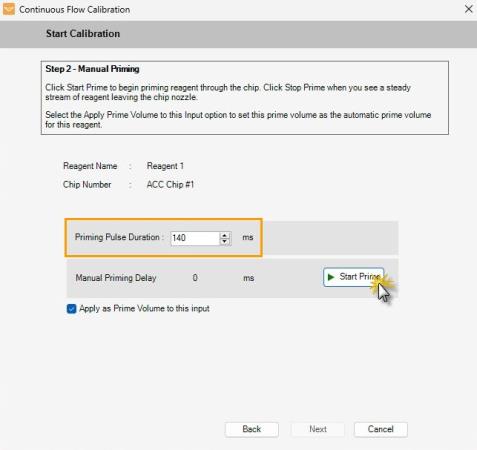

Define the Priming Pulse Duration value for priming. Then, click Start Prime to begin priming the reagent. Click Stop Prime when an uninterrupted stream of reagent leaves the chip nozzle. Then, click Next.

Priming the Chip

-

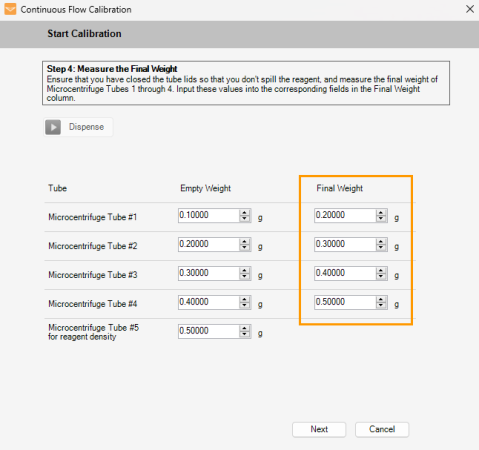

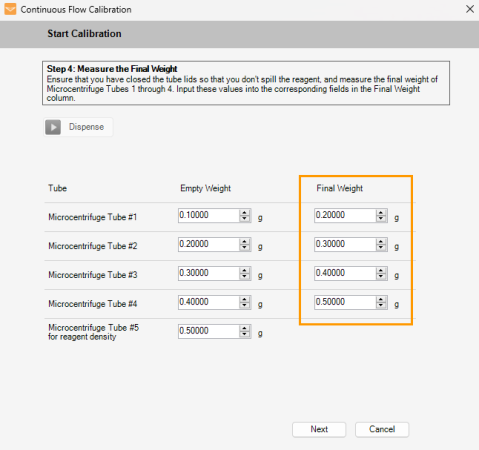

Click the Dispense button to dispense the reagent. After the dispense is finished, weigh each tube, then type the weight value (in grams) in each Final Weight field. Click Next.

Type the Weight Value in Each Final Weight Column

-

OPTIONAL: To calculate the reagent density:

-

Manually add 1 mL of the reagent to the empty tube in position 5 using a syringe or calibrated pipette.

-

Weigh the tube, and type the final weight (in grams) for microcentrifuge tube #5 under the Final Weight column.

-

See the following options:

-

For the standard CF chip, click Calculate.

-

For the HVCF chip, click Next. If prompted for an additional measurement by the software, continue to step e.

Define the Reagent Density

-

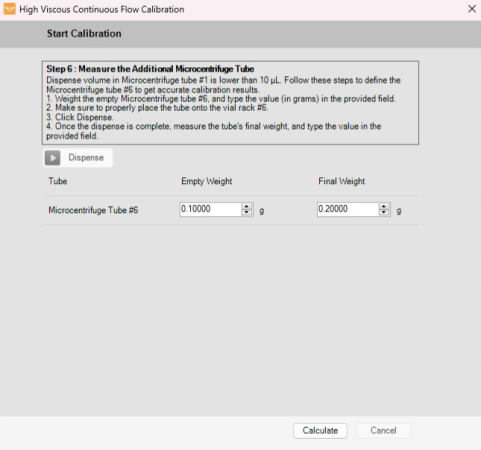

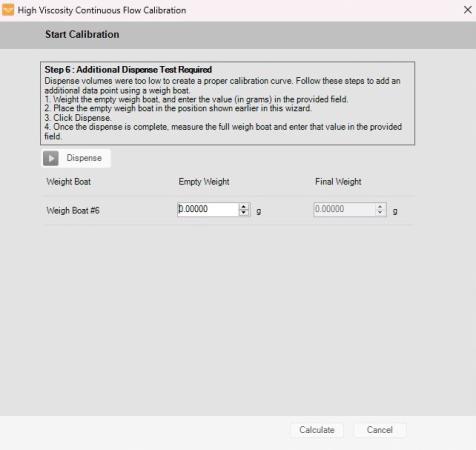

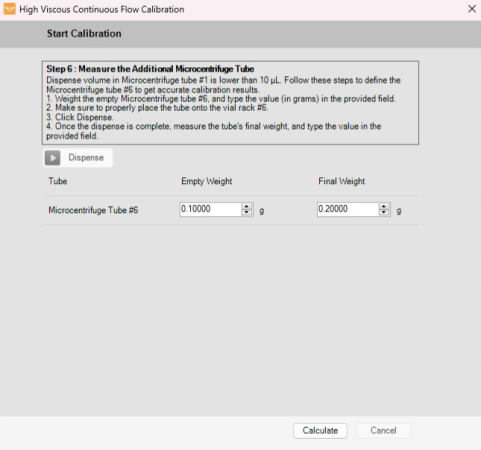

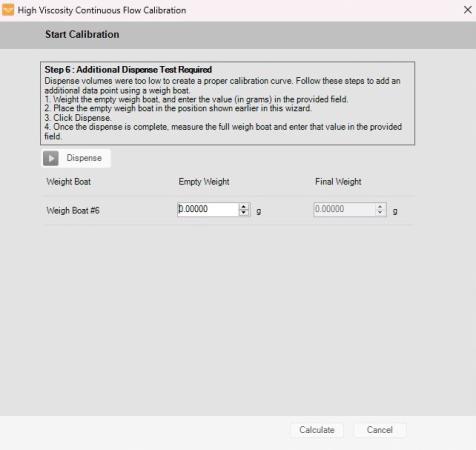

OPTIONAL for HVCF chip: Follow the on-screen instructions to fill and weigh microcentrifuge tube #6. Once it’s finished, click Calculate.

Define the Additional Measurement

-

Continue to step 3.

|

| Weigh Boats

|

-

Follow the on-screen instructions to prepare the Weight Boats.

-

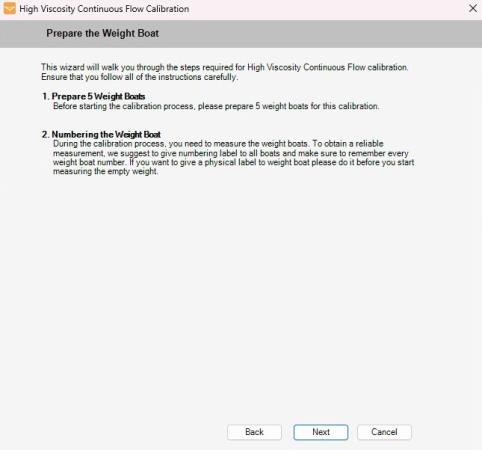

For standard CF chip:

If you have not previously defined the reagent density prepare 5 weigh boats, as shown in the image.

Prepare 5 Weight Boats

-

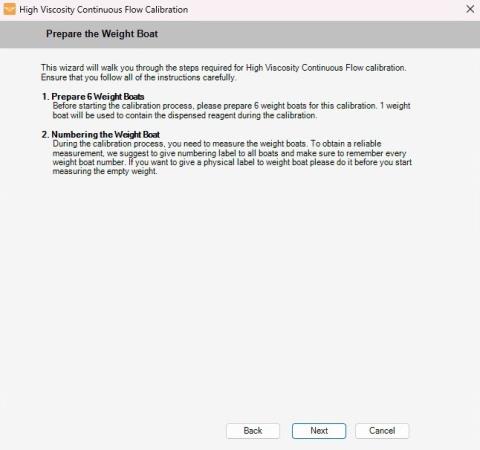

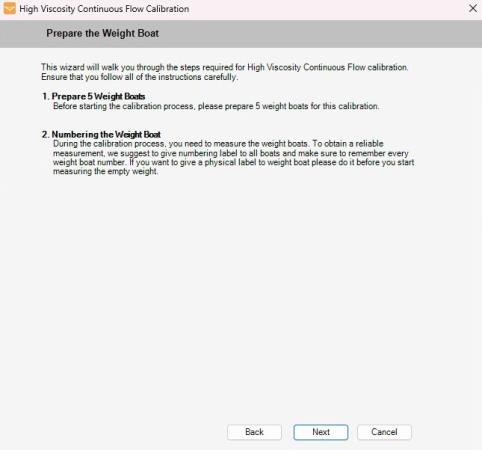

For HVCF chip:

If you have not previously defined the reagent density, prepare 6 weigh boats. The software may also prompt you to run an additional measurement in weigh boat #6, if necessary.

Prepare 6 Weight Boats

-

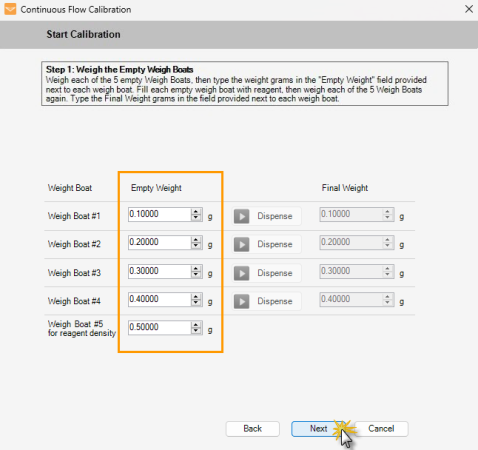

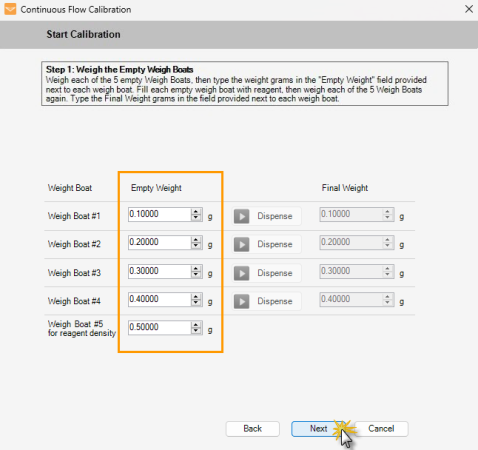

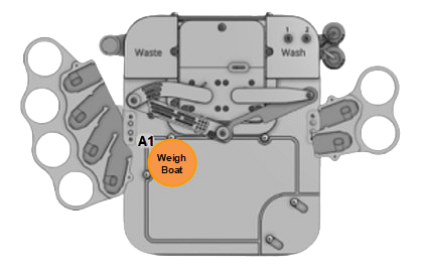

Weigh each empty weigh boat using the balance. Type the value (in grams) in each Empty Weight field. Click Next.

Type the Weight Value in each Empty Weight Column

-

Start the calibration:

-

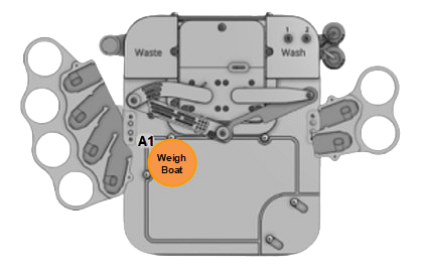

Place a weigh boat in the A1 position on the MANTIS deck, as seen below. Then, click Next.

Place the Weigh Boat in A1 Position on the MANTIS Deck

-

Define the Priming Pulse Duration value for priming. Then, click Start Prime to begin priming the reagent. Click Stop Prime when an uninterrupted stream of reagent leaves the chip nozzle. Then, click Next.

Priming the Chip

-

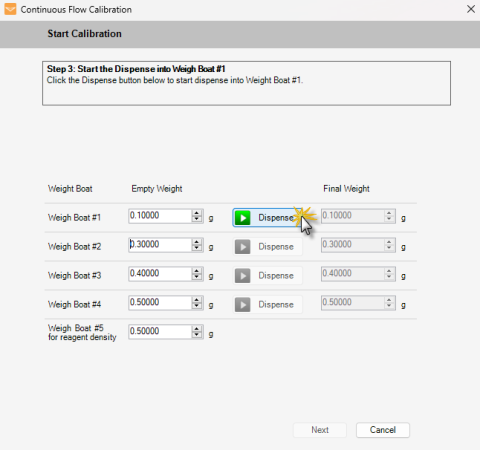

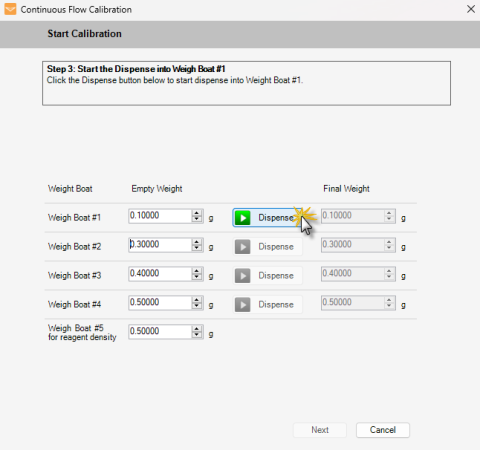

Click the Dispense button to dispense the reagent into each weigh boat.

Click the Dispense Button

-

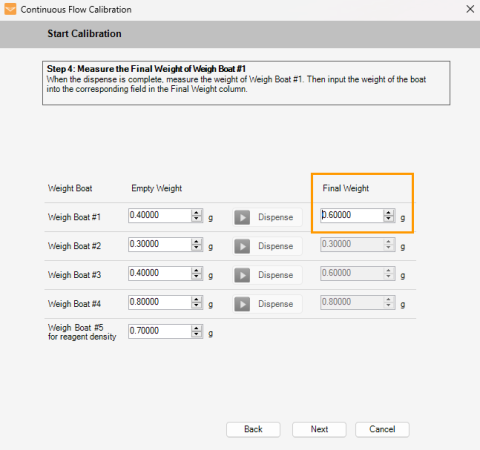

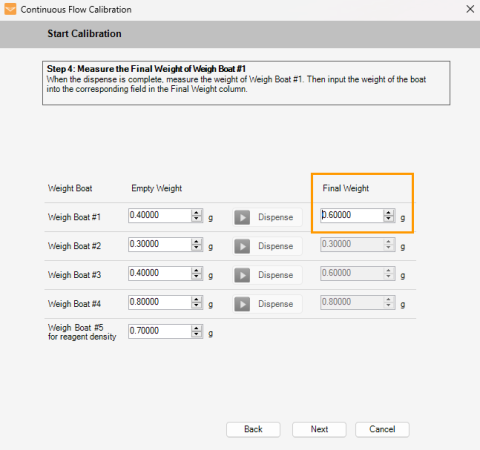

After the dispense is finished, weigh the full weigh boat and enter the value (in grams) in the field under the Final Weight column.

Type the Final Weight

-

Click Next to define the other three weigh boats.

-

OPTIONAL: If you did not previously define your reagent density, follow these steps:

-

Prepare and label a fifth weigh boat, then proceed to step 2 above.

-

Add 1 mL of the reagent using a calibrated pipette to the empty weight boat.

-

Then, weigh the weigh boat and type the weight (in grams) in Weigh Boat #5 under the Final Weight column.

-

See the following options:

-

For standard CF chip, click Calculate.

-

For HVCF chip, click Next. If prompted for an additional measurement by the software, continue to step g.

-

OPTIONAL for HVCF chip: Follow the on-screen instructions to fill and weigh weigh boat #6. Once it’s finished, click Calculate.

Define the Additional Measurement

-

Continue to step 3.

|

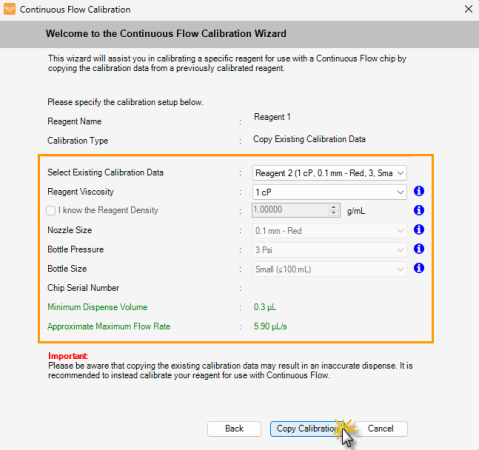

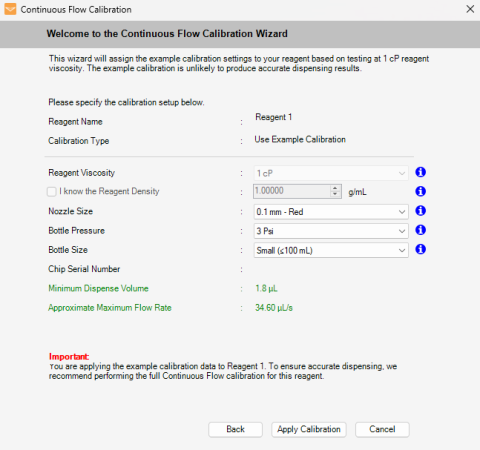

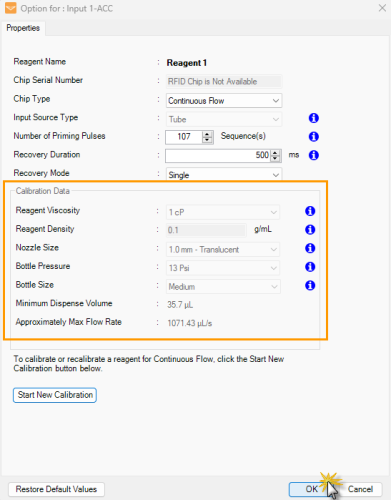

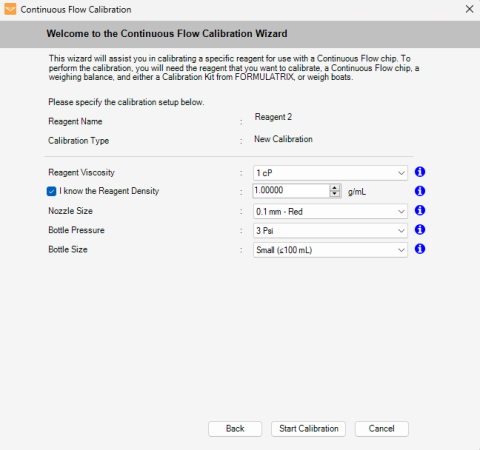

appears next to the Nozzle Size or Bottle Pressure field, hover over it to see the recommended bottle pressure and nozzle size values from MANTIS.

appears next to the Nozzle Size or Bottle Pressure field, hover over it to see the recommended bottle pressure and nozzle size values from MANTIS.