The Liquid Classes feature allows you to accurately dispense reagents of varying viscosity. MANTIS comes with default liquid class groups, each with its own optimized dispense settings. You can create a custom liquid class to optimally dispense various unique or difficult reagents.

Read the sections below to learn about the liquid class overview, liquid class, how to create a custom liquid class, and liquid class recommendations for dispensing.

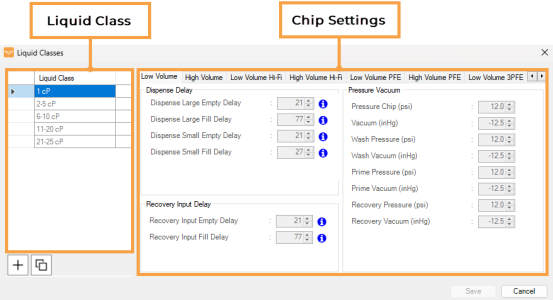

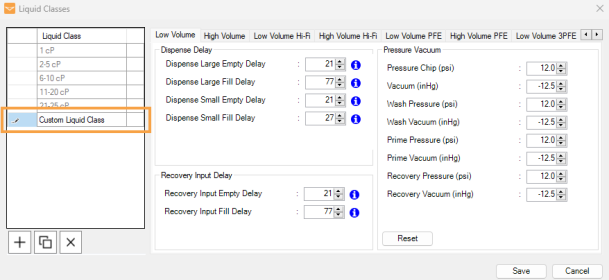

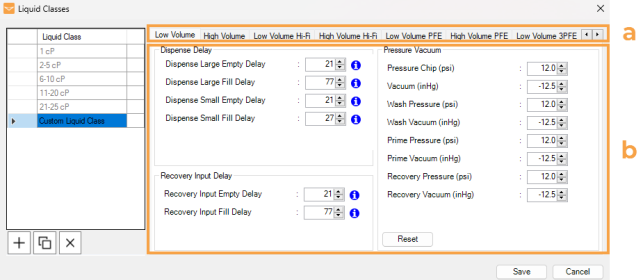

The Liquid Classes window, accessible from the Tools menu, allows you to manage liquid classes. There, you will find 2 main panels: Liquid Class and Chip Settings.

The Liquid Class column lists all the available liquid classes. Each liquid class has an associated Chip Settings section that allows you to adjust dispense delays and pressure/vacuum levels for each chip type.

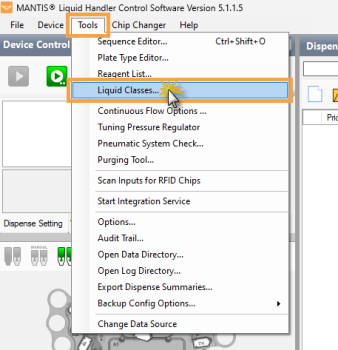

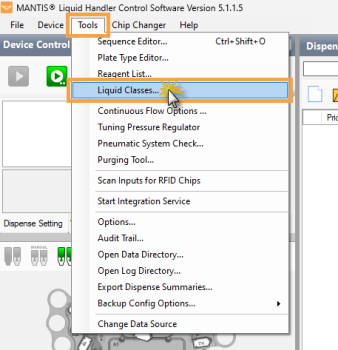

Select Liquid Classes Option

Liquid Classes Window

The following are the default liquid classes:

Note: The centipoise (cP) is a unit of dynamic viscosity. It corresponds to the resistance of liquid to flow. At 20°C, the viscosity of water is about 1 cP.

Under the Liquid Class column, there are functional buttons you can use to manage your liquid classes:

Add New Liquid Class allows you to create a new liquid class.

Add New Liquid Class allows you to create a new liquid class.

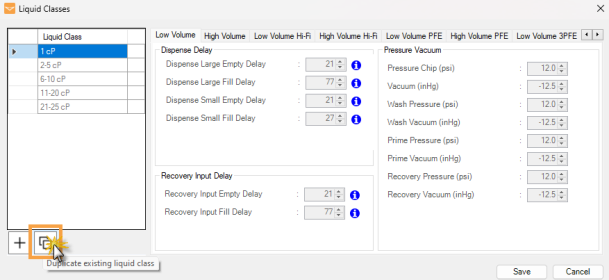

Duplicate Existing Liquid Class allows you to duplicate the selected liquid class, which can then be modified.

Duplicate Existing Liquid Class allows you to duplicate the selected liquid class, which can then be modified.

Delete Selected Liquid Class allows you to remove a user-created liquid class. This button is available once you create a new/custom liquid class.

Delete Selected Liquid Class allows you to remove a user-created liquid class. This button is available once you create a new/custom liquid class.

Empty Delays: The time for which the diaphragm remains under pressure, enabling the reagent expulsion from the cavity. While it has minimal impact on most liquids, highly viscous reagents may benefit from slightly longer empty delays to ensure complete expulsion.

Fill Delays: This is the primary parameter for customizing a liquid class. It defines the time the diaphragm experiences a vacuum, allowing reagent inflow to fill the cavity beneath the diaphragm. Longer fill delays work better with more viscous reagents.

Empty Delays: The time for which the large diaphragm remains closed while the chip is being emptied during recovery.

Fill Delays: The time for which the large diaphragm stays open while the chip is being filled during recovery.

Pressure and Vacuum: The Chip and Output pressure/vacuum settings control the actuation of diaphragms and valves, respectively. Higher pressure and/or vacuum results in more rapid diaphragm actuation and provides a minor benefit when working with more viscous reagents.

Note: Coordination between pressure/vacuum and delay timing is crucial for efficiently dispensing liquids of different viscosities.

To create a custom liquid class, we recommend you start by duplicating a default liquid class and then customizing the parameters. It is essential to set the delay and pressure vacuum values to fall within the range defined by the default MANTIS liquid classes. Using values that are out of range may affect the accuracy and precision of the dispense.

In the Liquid Classes window, choose from the following options:

Click the Add new liquid class button.

OR

Select a default liquid class of your choice, and then click Duplicate existing liquid class.

Duplicating a Default Liquid Class

Define the new liquid class name, and press Enter on your keyboard.

The Duplicated Liquid Class

Modify the dispense settings by following these steps:

Important: The Pressure Vacuum settings should not be altered unless you are directed by FORMULATRIX support to do so, as it may adversely affect dispense accuracy. If you are an authorized user, see the recommendations below to adjust the pressure/vacuum settings.

Define the dispense delay, recovery input delay, and pressure/vacuum settings as needed.

Important: We recommend you to use silicone or 3PFE chips for viscous reagents. For more information about chemical compatibility with FORMULATRIX chips, click here.

Modify the Settings for Each Chip Type

Repeat steps a-b to modify the settings for the other chip types as needed.

Click Save to save the new liquid class and close the window.

Important: The delay and pressure/vacuum settings of the MANTIS default liquid classes cannot be modified or deleted.

To edit an existing liquid class, click on the selected liquid class, and modify the settings as needed.

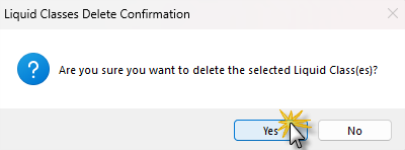

To delete an existing liquid class:

Select the liquid class you want to delete. You can use the Ctrl key to select multiple liquid classes.

Click the Delete selected liquid class button.

Then, click Yes on the pop-up message.

Liquid Class Delete Confirmation

Important: These liquid classes are unable to be deleted:

- Default liquid classes.

- Any liquid class assigned to a reagent in the Reagent List.

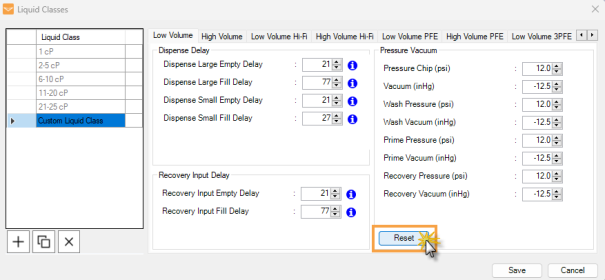

Click Reset to revert to the default settings.

Click the Reset Button

Click Save to save the changes.

The list below is the general recommendations for creating a custom liquid class in MANTIS. Actual effects may vary based on specific liquid properties, hardware conditions, and other external factors. Always perform iterative testing to find optimal settings.

A moderate pressure and vacuum with short dispense delays are sufficient as low-viscosity liquids flow easily.

Use the standard fill delays and empty delays.

No adjustments to pressure/vacuum settings are required.

Consider reducing the pressure while increasing the empty delay for gentle dispensing or to avoid splashing. This can be helpful with cells or reagents that are prone to foaming.

High-viscosity liquids flow into the diaphragm cavity slowly, often necessitating higher pressure/vacuum and prolonged delays.

Increase fill delay to accommodate the slower inflow. Consider increasing the fill delay further if under-dispensing is observed.

Extend empty delay to ensure complete evacuation of the reagent. However, increasing the empty delay will not be necessary for most reagents.

Slightly increase the vacuum (1-3 inHg) to ensure the complete filling of the diaphragm cavity.

Elevate the pressure (1-3 psi) for effective expulsion of the liquid.

Consider increasing the pressure and empty delay to avoid hanging droplets on the nozzle. Using a smaller nozzle ID can also help avoid droplet formation when working with viscous reagents.

Important: Always maintain a consistent difference of 5 psi for pressure and 5 mmHg for vacuum between chip and output settings, or see the formula below.

Output Pressure/Vacuum = Chip Pressure/Vacuum + 5

DO NOT exceed 21 psi for pressure or -18 inHg for vacuum. Doing so could damage your MANTIS instrument.

|

|

| MAOWH-V5R124 |