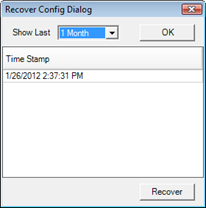

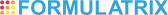

Automatic plate definition file backup

In the interest of protecting and preserving your plate definition files -- which contain vital information about how to image each plate type -- plate definition files are now automatically backed up on a weekly basis.

Recover Plate Definition dialog box

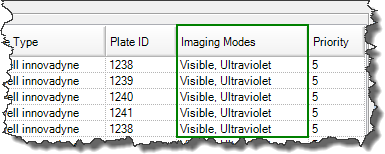

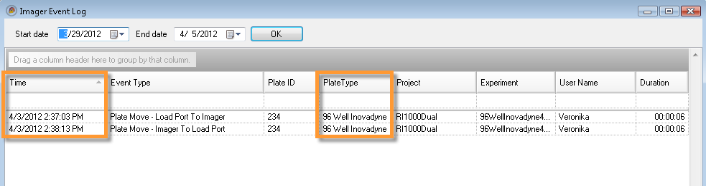

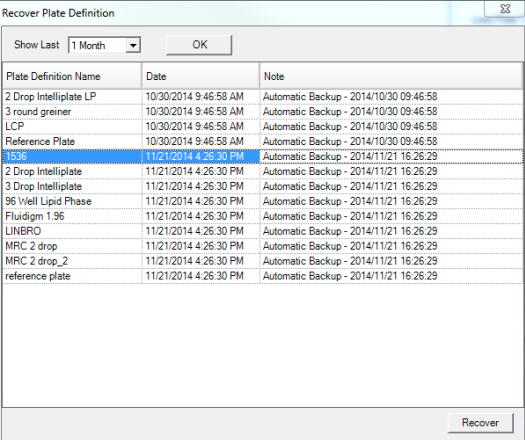

New columns in Imager Event Log

The Imager Event Log now includes columns for “Inspection ID” and “Imaging Setting”.

Imager Event Log

Excessive time in manual mode alerts

If Rock Imager is left in manual mode for more than six hours, Rock Imager will email Formulatrix support to check on the imager. If the imager was accidentally left in manual imaging, a support technician will return the imager to its automatic imaging schedule, so as not to create a large imaging backlog in the system.

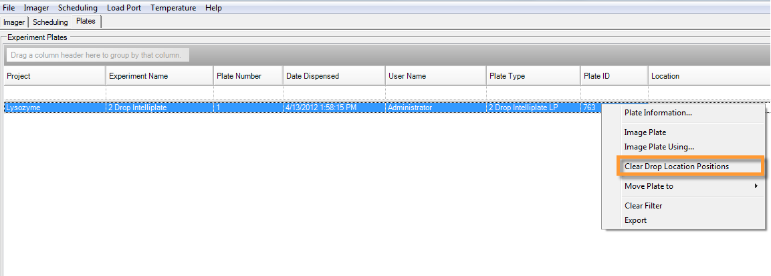

Improved automated image queue management

Previously, if someone initiated an "image now" command from Rock Maker when Rock Imager is in manual mode, Rock Imager would immediately switch to automatic mode in order to start imaging the plate. Now, the plate will be queued until Rock Imager is switched back into automatic mode, so as not to interrupt manual imaging.

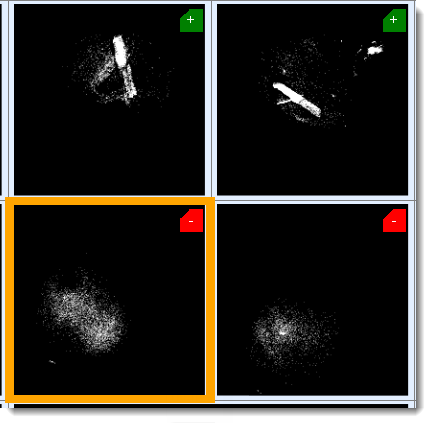

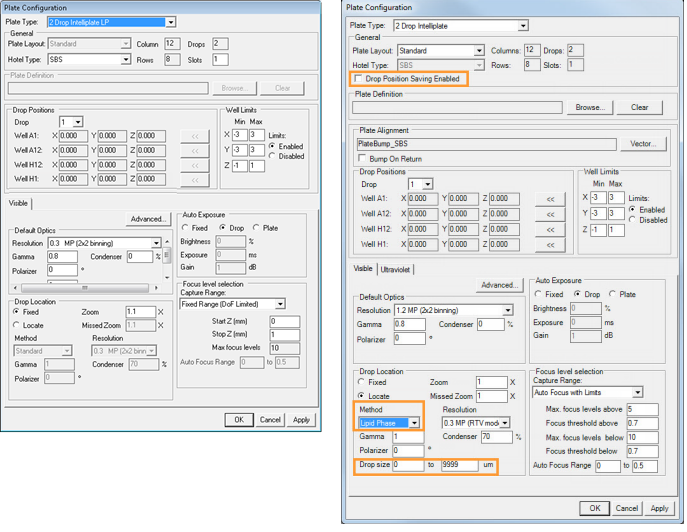

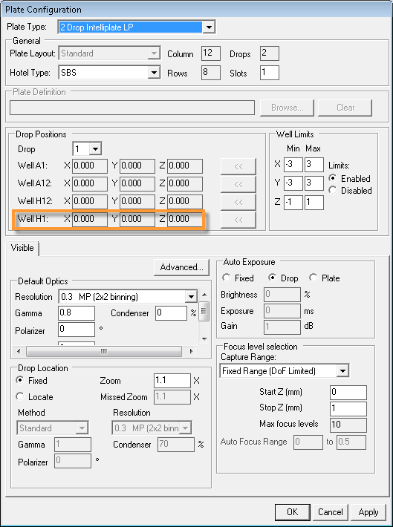

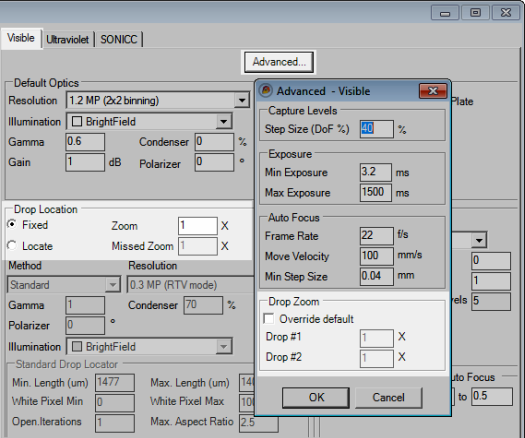

Individual drop zoom settings for multi-drop plates

By adding a new control to the Plate Type Editor's Advanced dialog box, we have made it easier to image plates that have multiple drops of different volumes, such as the Intelli-Plate. You can now assign individual zoom settings to each drop at a well.

Set drop zoom on a per-drop basis

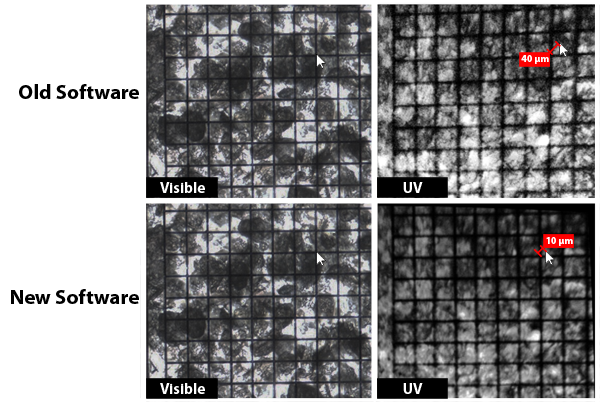

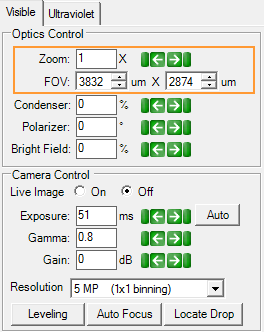

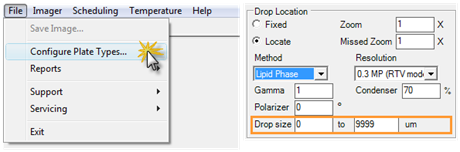

‘Blob Size’ now in µm

For ease of interpretation when troubleshooting and tuning drop location, blob sizes are now measured in µm instead of pixels. This change also makes the blob size value independent of image resolution/binning and pixel size.

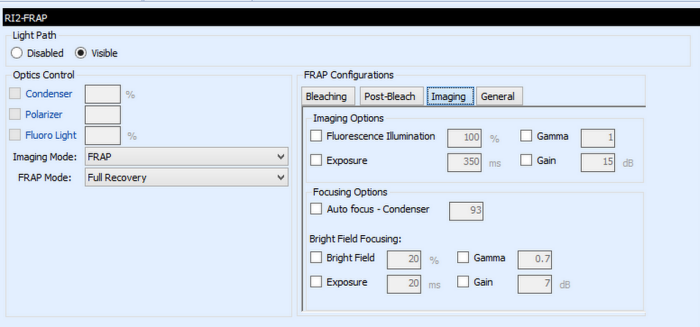

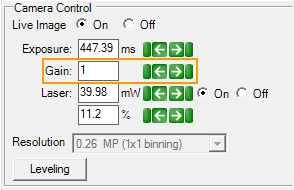

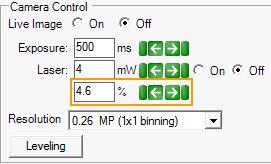

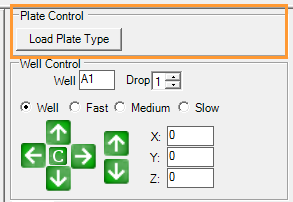

More precise brightness controls

In order to increase brightness control precision, the brightness control buttons have been made less sensitive. Now, a single click in the positive or negative direction equals one increment change. Previously, the control was more sensitive, and it was possible to accidentally adjust the control more than desired with a single click.