Rock Imager 3.4 includes some improvements for all types of imagers and optical setups to make your research easier. Here is a quick look at some of the new developments for Rock Imager 3.4.

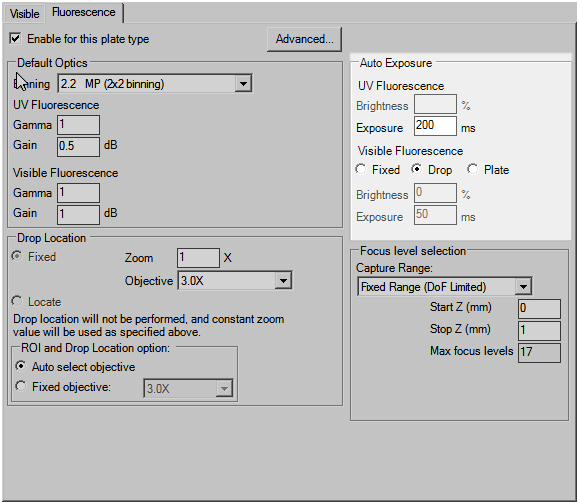

Auto exposure settings for Visible Fluorescence

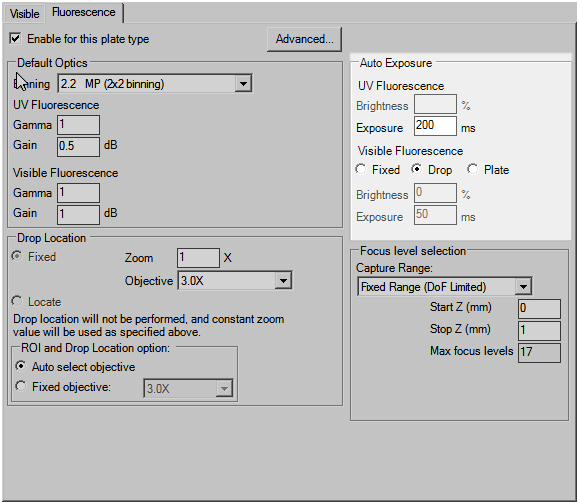

Rock Imager licensing email notification

Improved SONICC Exposure field with added narrow buttons

Complete Imaging Mode information in Rock Imager scheduler

Rock Imager has added several minor changes for better usability. Other changes include:

Added a notification when a user tries to move the reference plate to the load port. The reference plate can only be moved by administrators or Formulatrix support, for troubleshooting purposes.

Added a SONICC laser warning notification to inform the user when the laser is turned off.

Added larger dialog boxes to the Rock Imager Tools panel to make it easier to find what you are looking for.

Added more information to the Rock Imager Processor log file to make it easier to distinguish between multiple Rock Imager systems.

The ‘Lost Rock Maker Database Connection’ notification will display until the connection is regained. A notification panel also appears in the Rock Imager status bar.

Changed Rock Imager scheduler so that the “*” schedule priority value can now be edited.

Many of the best Rock Imager updates have been suggested by our awesome user community!

Have a great idea on how to make Rock Imager better? Let us know by contacting us at support@formulatrix.com.

Optimized Condenser Imaging

Just as polarized imaging has been improved in the previous version of Rock Imager, Rock Imager 3.3 now also optimizes condenser imaging for a faster imaging process and more accurate results. With this new optimization, condenser imaging will be completed first across the entire plate, rather than Rock Imager switching between imaging modes for each well.

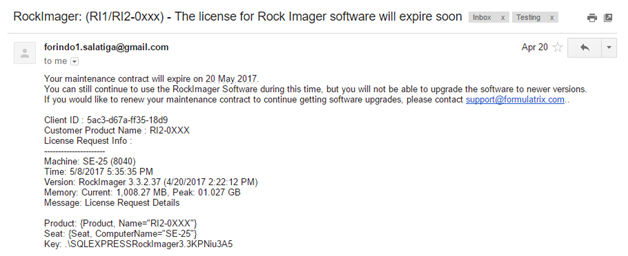

Revamped Temperature Monitor

The Temperature Monitor’s interface has been significantly improved, allowing you to analyze your system’s temperature at a glance. Now you can display all of the available temperature data from any given range of time. For easy data comparison, you can select multiple sensors to be displayed at the same time. You can also use the mouse wheel to zoom in and out of the temperature graph to view different data intervals, such as hours, minutes, or even seconds. For more information, please read Viewing Temperature Graphs.

Temperature Monitor

Better Imaging Results with Fixed Exposure on Single Light Path (SLP) Systems

Fixed exposure can now be set individually for each objective on SLP systems, providing you with better image quality than ever before. This is particularly useful for drop location where the different objectives are used from drop to drop. You can find this new feature in the Plate Type Editor on the Advanced Tab under Fixed Exposure. Check the Override Default box to edit. If you have any questions on how to optimize your exposure times, Formulatrix support is always available to help. For more information, please read Using the Plate Type Editor.

Override Exposure option in the Visible and UV Advanced tab of the Plate Type Editor

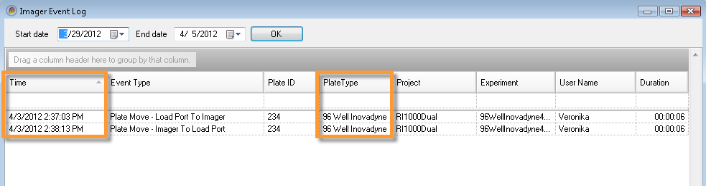

Improved Imager Event Log

Save time by specifying the time frame of interest in the Rock Imager event log to show only the data that you are looking for.

Automatically Locate Empty Slots with Smart Imager Hands

Now Rock Imager 182 and 54 systems will automatically find an empty storage slot for a plate, should that plate’s usual slot be full. If you add a new plate in Rock Imager to a slot that had been occupied by a plate on the imager hand, the imager will automatically find a new slot for the plate being imaged when imaging is complete. If all slots are currently occupied, you will receive a notification in the Rock Imager software, so that you can reorganize your plates.

New Alert Notification for Laser Power

Rock Imager 3.3 now sends you and our support team an email notification should the laser power increase by more than 100%. Large fluctuations in laser power may indicate that there is a problem with your SONICC system. This notification allows support to quickly investigate any potential issues, while minimizing the disruption to your work.

Digital Zoom for 9 Megapixel Cameras

Now all Rock Imagers with nine megapixel cameras, including new systems, have the ability to use digital zoom with fixed objectives. This enables you to tighten the field of view perfectly to the edges of your drops. The digital zoom is achieved by cropping the images acquired by the camera. For more information, see Using Optics Control.

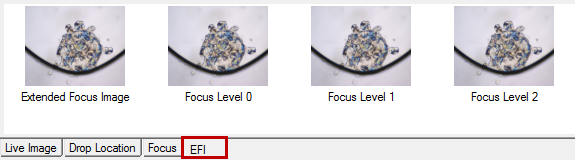

Capture Extended Focus Images (EFI) with a Single Click

Rock Imager's EFI functionality now includes the ability to view and save extended focus images within Rock Imager. Just click the EFI button on the Camera Control panel to see and save your images, without having to switch to Rock Maker. For more information, see Extended Focus Image (EFI) Sub-Tab.

An EFI displayed on the EFI sub-tab

Optimized Polarized Imaging

Rock Imager 3.1 features polarized imaging optimization to speed up the imaging process and preserve accurate exposure for better images. Using the new optimization, whole plates will be imaged using the selected imaging modes, rather than Rock Imager switching between imaging modes for each well.

Dynamic Image Scheduling

Plates will now be sent to the imaging queue 4 hours before their scheduled imaging time to reduce wait times between imaging sessions. This occurs only when Rock Imager is idle, so affected plates will be imaged directly if there is no other imaging session currently taking place. For more information, see Scheduling Tab.

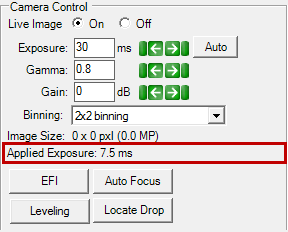

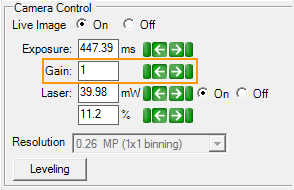

View the Applied Exposure on Live Images

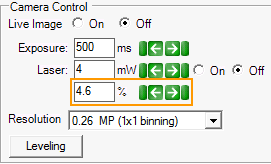

Rock Imager now displays the applied exposure value for live images on the Camera Control panel. This shows you the exposure value as adjusted by binning exposure compensation. By default, binning exposure compensation is enabled for all visible light images and disabled for all UV images for both PointGrey and PixeLINK cameras. To read more about binning, see Using Camera Controls.

The Applied Exposure on the Camera Control panel

Eject Expired Plates Automatically

Rock Imager makes it even easier to manage plates in storage with the ability to automatically move expired plates to the load port. You will be notified via email when plates are moved so you can keep track of where plates are located. This feature can be enabled from the Load Port menu in Rock Imager and is configured to run from 9:00 to 17:00 Monday through Friday. To change the time settings, please contact support.

FRAP data is retained even when focus level saving is disabled

You can now disable saving individual focus level images and still retain all the associated FRAP information. All associated FRAP images, such as pre-bleach, end-state and charts, will be saved regardless of database management and whether or not visible or UV focus level images are saved.

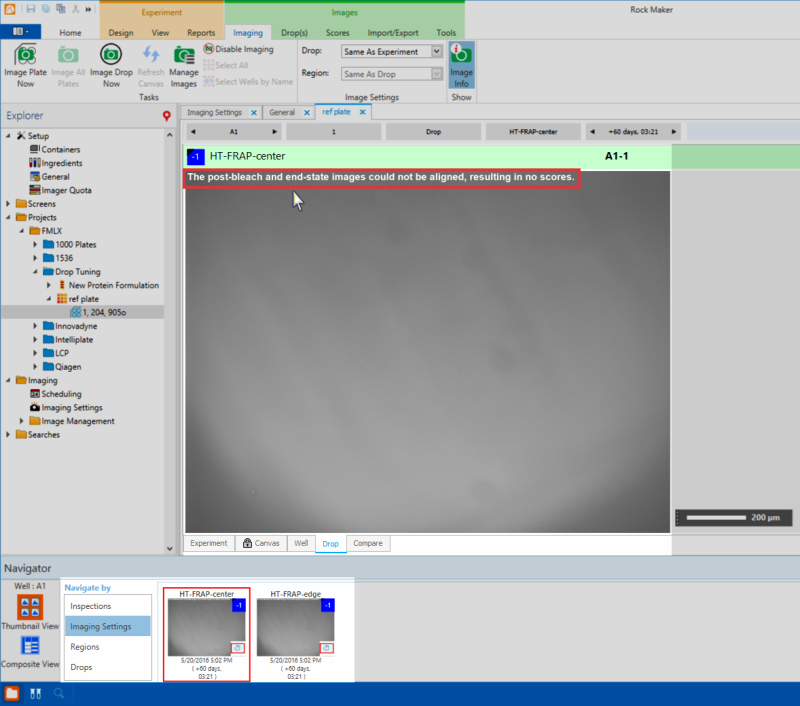

Validation added to ensure accurate FRAP results

When analyzing a plate with High Throughput FRAP, Rock Imager uses a software algorithm to align the pre-bleach and end-state images. If the algorithm fails to align the images within the specified offset tolerance, no FRAP results are calculated. Instead, an image with an error message is displayed in Rock Maker and a score of “-1” is given, alerting you to the FRAP analysis failure. For more information, see Interpreting FRAP Offset Information.

HT-FRAP images on Rock Maker

Move multiple plates to the load port

Managing plates is easier now that Rock Imager enables you to move any number of plates to the load port at once, saving you time. If the load port is currently full, the plates will remain queued and automatically be moved as space becomes available. For more information, see Removing Plates.

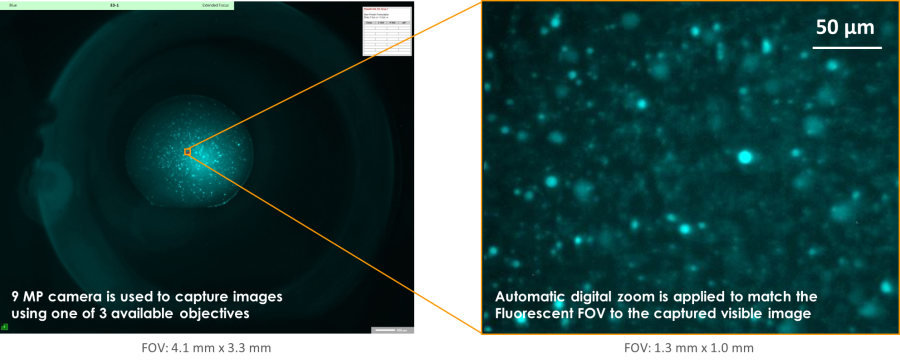

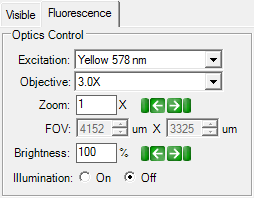

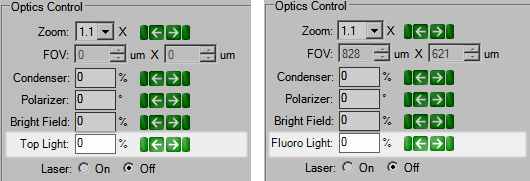

Adjust the Field of View (FOV) with continuous zoom imaging

In addition to the multiple objectives available, Rock Imager MFI allows for continuous zoom imaging. This control enables you to tighten the FOV perfectly to the edges of your drops and is achieved by cropping the images acquired by the camera. The FOV for fluorescent images will match the FOV for visible images for comparison purposes. For more information, see Using Optics Control.

Fluorescence Optics Controls

Optimized plate handling

With optimized plate handling, Rock Imager will no longer acquire drop overview images for drop locations that have previously been defined in Rock Maker. This is especially useful for double imagers, allowing plates to be imaged immediately in SONICC without first having to go to the visible imager to acquire an overview image.

Other ways Rock Imager 3.0 can make life easier:

The display for resolution and image size have been split up and renamed as “Binning” and “Image Size” to accurately display the size of the image in pixels. For MFI images, the image size will be affected by the zoom control and image cropping on the camera.

Labels for the temperature sensor were changed from "Mid Back" and "Top R" to “Middle” and “Top”.

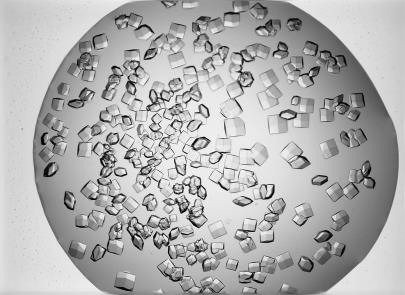

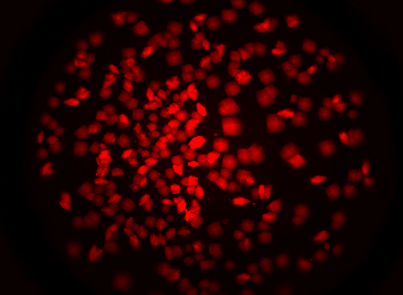

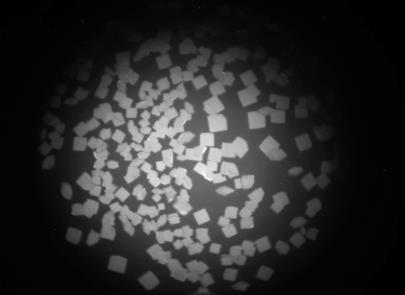

Rock Imager 2.17 supports two new imaging types: Multi-Fluorescence Imaging and UV absorption Imaging. Rock Imager 2.17 is a limited release for RI-1000s and RI-2s that include either of these imaging types.

|  |

|  |

MFI sample images - Visible, Texas Red, Ultraviolet, and Fluorescein (cyan)

Ultraviolet (UV) Absorption Imaging

UV absorption is a new hardware setup that allows scientists to acquire absorption images. The UV absorption imager transmits UV light through the sample and then detects the same wavelength UV light on the camera. Areas that absorb the UV light create contrast, allowing you to see differentiating features in your crystallization drops. UV absorption can be helpful for imaging drops that are not UV fluorescence, for example, DNA, RNA, and proteins without tryptophan. For more information, see UV Absorption Imaging .

UV absorption imaging samples

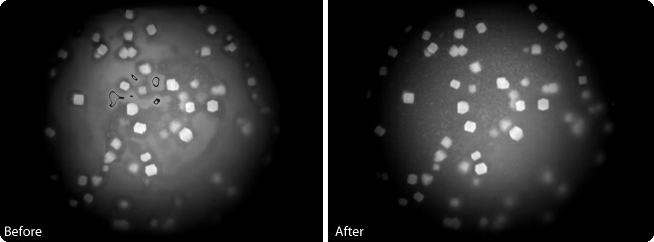

Improved Drop Location

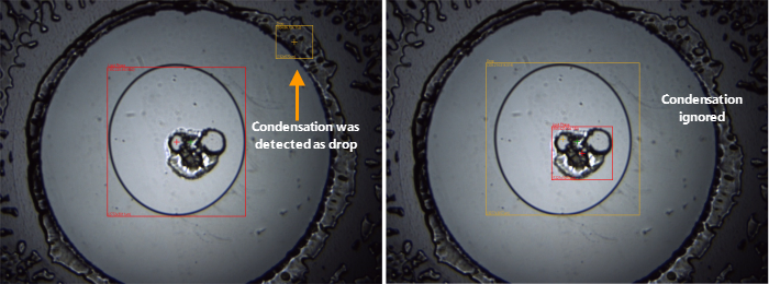

Rock Imager’s drop location algorithm has been improved to differentiate droplet condensation, LCP plate tape, and semi-circular objects from sample drops.

| Before improvement | After improvement |

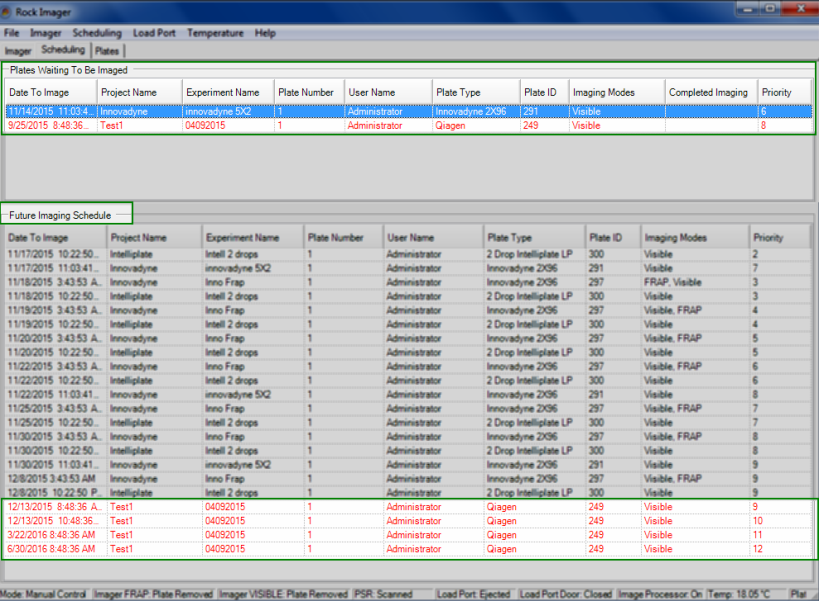

Better handling of troubled plates

“Troubled” plates, or plates that were not able to be imaged due to barcode label issues and/or plate alignment issues, are now listed in the Plates Waiting To Be Imaged and Future Imaging Schedule tables in red text. These plates will be skipped and not imaged as scheduled until the problem is resolved. Contact Formulatrix support if you need assistance handling troubled plates. For more information, see Scheduling Tab.

Troubled plates marked in red text

More accessible SONICC reference plate data

A new SONICC reference plate data analysis menu provides the ability to both view and export reference plate data analysis directly from Rock Imager and execute the reference plate image and analysis routine with a quick click of a button. To take advantage of this feature, benchtop users must contact support to properly create initial readings that will be used as a benchmark for comparison purposes during subsequent imaging and analysis. For more information, please see SONICC Reference Plate Image Analysis.

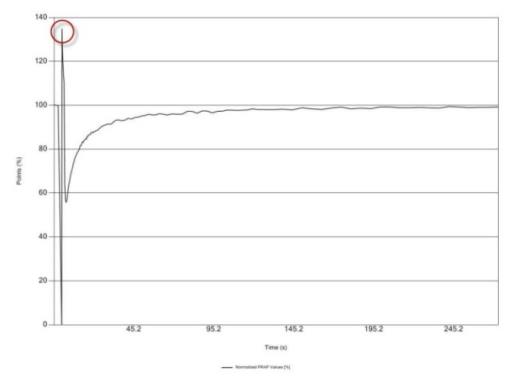

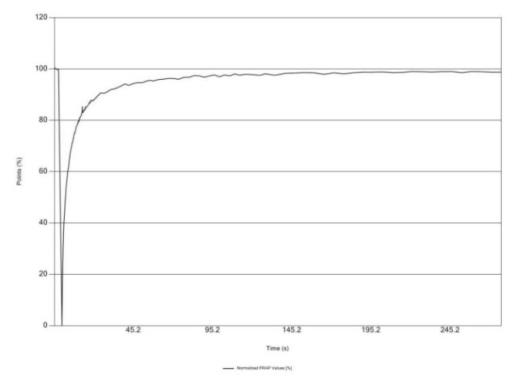

Improved FRAP diffusion rate calculations

FRAP Full Recovery diffusion rate calculations are now more accurate due to constraining the image alignment algorithm. A calculated image overlay deviation greater than 10 pixels (~ 12 µm) are assumed to be inaccurate and a (0 µm, 0 µm) delta data point is used instead.

|

|

| Before improvement -- notice invalid data point affecting curve graph (circled in red) | After improvement |

Additional FRAP imaging data available in Rock Maker

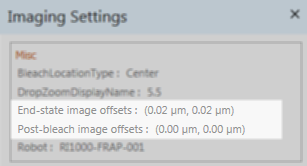

Two new FRAP imaging parameters, “End-State image offsets” and “Post-Bleach image offsets” are now available on Rock Maker’s Imaging Settings tab for high-throughput FRAP imaging sessions. If the difference in the measurements of the Post-Bleach and the End-State image offset values is too great, the imager may be experiencing abnormal plate movement during imaging which could cause invalid mobile fraction and recovery curve data. For more information, see Interpreting FRAP Offset Information.

Offset values in Rock Maker

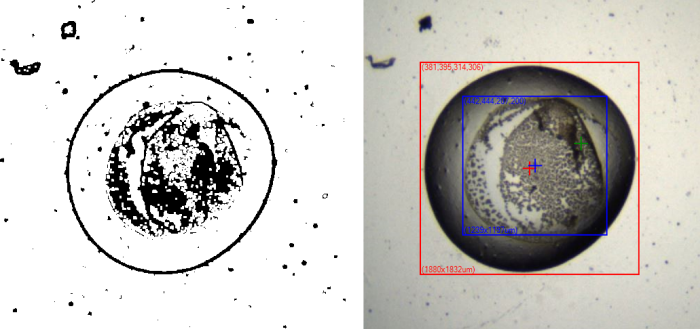

Enhanced automatic drop location

The automatic drop location detection algorithm has been enhanced to identify the larger circular “blobs” instead of smaller subsections of the drop that previously resulted in false positives. The image below shows the blue box that had previously been used as the drop location and now the red box correctly locating the protein drop. False positives from condensation droplets have also been reduced by changing the maximum aspect ratio to 1.5.

Enhanced automatic drop location

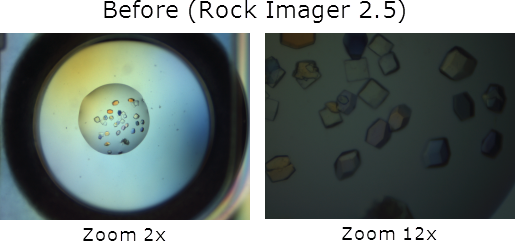

Improved Auto-Exposure

The auto-exposure algorithm has been modified to provide better images when executing the Auto-Exposure command. The code has also been adjusted to support different settings for the various cameras we have installed in the field.

Image Now imaging priority read from Rock Maker

The automated imaging schedule now stays properly prioritized despite on-demand imaging requests from Rock Maker users, as Rock Imager now reads imaging priority from Rock Maker “image now” commands, including image plate now, image drop now, and image plates now (multi-plate experiments). Requires Rock Maker 3.2.4.5 or newer.

New online help file

The help file is now hosted online so that you have immediate access to the most up-to-date information. If your imager does not have internet access, Rock Imager will load a local version of the same file which will load in a web browser.

Plate location information sent to Rock Maker

Rock Imager now sends additional information about plate location to Rock Maker. In the future, Rock Maker will show customers if a plate is not in an imager, and provide information about which imager a plate is located in if a customer has multiple systems. Rock Maker will also disable all “Image Now” commands if a plate is not inside an imager.

Rounded UV zoom values

Zoom values for UV imaging are now rounded to the tenths decimal place.

Automatic SONICC laser health monitoring

SONICC reference plate images are now analyzed to monitor the health of the SONICC laser. If image degradation is detected, Rock Imager sends an email alert. Relevant information has also been added to the nightly diagnostic email report.

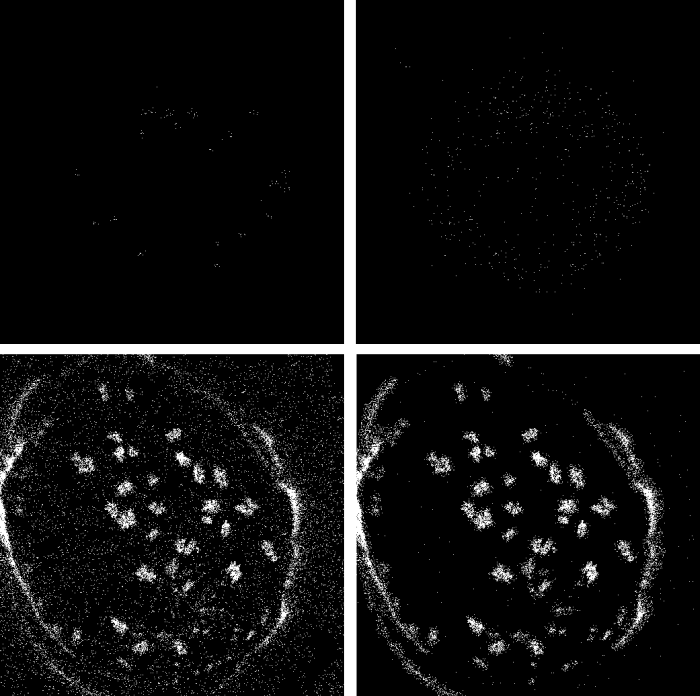

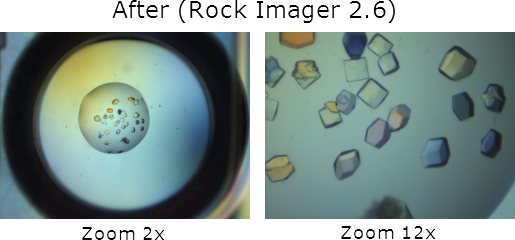

Better SHG Extended Focus Image (EFI) images

SONICC customers will notice better SHG EFI images due to some changes to the EFI algorithm, including reduced noise and inclusion or more “real” signal. The images below show the previous images on the left and the improved images on the right.

Before SHG EFI improvement After SHG EFI improvement

Better SONICC laser life

If the SONICC laser will not be used for two or more hours according to the automatic imaging schedule, the laser will be powered-off until next use to help extend laser lifetime.

Full Recovery FRAP data points exported to Rock Maker

Rock Imager’s ImagerLink now exports additional information about Full Recovery FRAP data points to Rock Maker. Future releases of Rock Maker will incorporate this additional information -- stay tuned!

Additional Full Recovery Intervals

Rock Imager can now be programmed to take more interval images during Full Recovery imaging sessions. Note that adding additional intervals increases total imaging time.

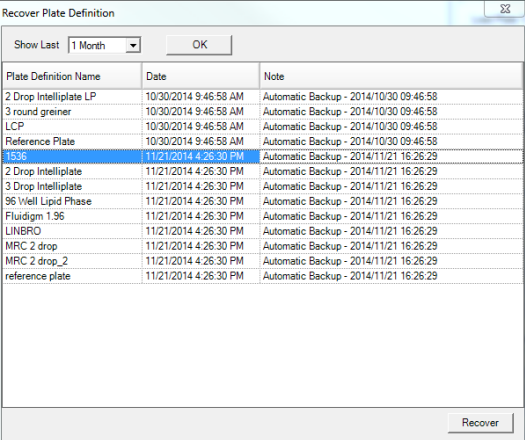

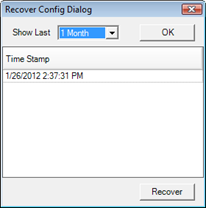

Automatic plate definition file backup

In the interest of protecting and preserving your plate definition files -- which contain vital information about how to image each plate type -- plate definition files are now automatically backed up on a weekly basis.

Recover Plate Definition dialog box

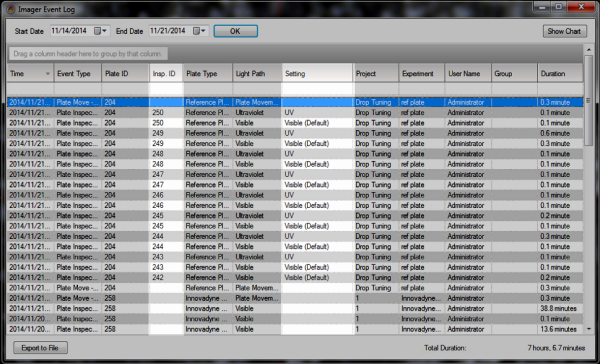

New columns in Imager Event Log

The Imager Event Log now includes columns for “Inspection ID” and “Imaging Setting”.

Imager Event Log

Excessive time in manual mode alerts

If Rock Imager is left in manual mode for more than six hours, Rock Imager will email Formulatrix support to check on the imager. If the imager was accidentally left in manual imaging, a support technician will return the imager to its automatic imaging schedule, so as not to create a large imaging backlog in the system.

Improved automated image queue management

Previously, if someone initiated an "image now" command from Rock Maker when Rock Imager is in manual mode, Rock Imager would immediately switch to automatic mode in order to start imaging the plate. Now, the plate will be queued until Rock Imager is switched back into automatic mode, so as not to interrupt manual imaging.

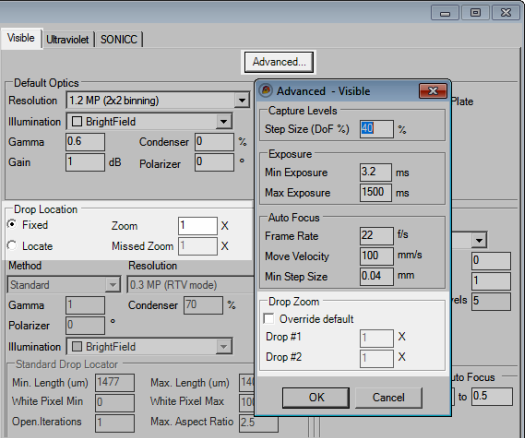

Individual drop zoom settings for multi-drop plates

By adding a new control to the Plate Type Editor's Advanced dialog box, we have made it easier to image plates that have multiple drops of different volumes, such as the Intelli-Plate. You can now assign individual zoom settings to each drop at a well.

Set drop zoom on a per-drop basis

‘Blob Size’ now in µm

For ease of interpretation when troubleshooting and tuning drop location, blob sizes are now measured in µm instead of pixels. This change also makes the blob size value independent of image resolution/binning and pixel size.

More precise brightness controls

In order to increase brightness control precision, the brightness control buttons have been made less sensitive. Now, a single click in the positive or negative direction equals one increment change. Previously, the control was more sensitive, and it was possible to accidentally adjust the control more than desired with a single click.

Rock Imager software disabled during system diagnostics

The Rock Imager software is now disabled during system diagnostics to avoid appearing non-responsive. Additionally, a progress bar appears to indicate system status.

Automatic laser health monitoring (SONICC dual imagers only)

Rock Imager product managers will now keep a close eye on the health of the lasers within SONICC systems by reviewing photographs taken of the reference plate under SHG and UV-TPEF light paths in your system on a bi-weekly basis. Images will be emailed to the product manager automatically.

Load Port scan behavior changes (Rock Imager 1000 only)

Plates are now left in the load port until further command after initial barcode scanning, allowing you to decide whether to manually image a plate or send it to storage. Previously, all plates were scanned and then picked up for automatic imaging, which created unnecessary delay if you wanted to manually image the plate.

Visual map of expired plates (Rock Imager 182 and 54)

Quickly identify the physical location of expired plates in a large visual display. Expired plates are indicated with red text and an EXPIRED label. To view the map, go to the Load Port menu and select View Expired Plates.

Expired plates in the load port

Monthly expired plate notifications

Rock Imager can now send monthly notification emails to you reminding you of any expired plates still residing in the imager's storage facilities.

Rock Maker imaging schedule status change (dual imagers only)

Previously, imaging sessions were reported as "completed" in Rock Maker when a plate had been imaged with one light path but was scheduled to be imaged under multiple light paths. Now, plates that have been imaged under one light path and are waiting to be imaged under the second light path will be reported as "imaging" until the plate has been imaged under both light paths.

Improved UV to Visible and SONICC to Visible image alignment

Due to lens distortion, you may have noticed the cursor was only aligned perfectly at the center of a drop when examining image results of different light paths in Compare Mode in Rock Maker. This is due to image curvature from lens distortion. In software we now "flatten" the image removing the lens distortion curvature resulting in improved cursor alignment when comparing images from different light paths. The distortion characteristics are unique to each system requiring a simple calibration to be performed to improve image alignment. To take advantage of this improvement, contact support to set up a tuning session.

Alignment improvements

Initial Live Image view fixed (SONICC only)

Previously, SONICC users would have to turn Live Image on, and then off, and then on a second time in order to see drops correctly. This issue has been fixed, and SONICC users will now see drops displayed correctly the first time Live Image is turned on.

Laser timeout now resets if stage movement is detected (SONICC only)

The automatic laser timeout, designed to protect both your samples and laser life, now resets when Rock Imager detects stage movement during manual imaging.

Smarter manual mode

Previously, if you canceled an imaging command made accidentally while in manual mode such as "image plate", you would have to re-scan the plate barcodes to continue imaging. Now, Rock Imager will remember the barcodes and allow you to continue without further interruption.

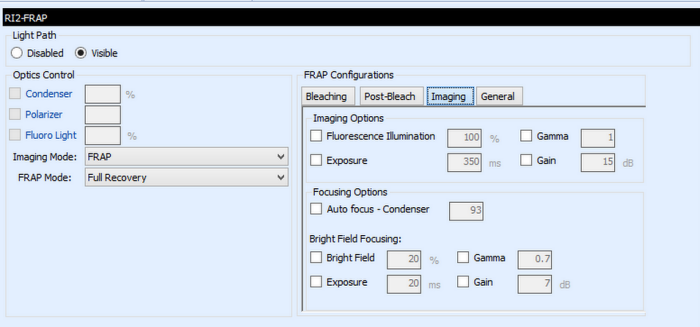

Default imaging setting values displayed in Rock Maker

For greater insight into how images are captured, the default FRAP imaging settings are now displayed in Rock Maker. These settings are accessible through the Imaging Settings node of the Explorer.

FRAP default imaging values in Rock Maker

"Top Light" now called "Fluoro Light"

To make FRAP imaging terms more familiar for new users, the term Top Light has been changed to Fluoro Light.

Before (left) and after (right) FRAP imaging term change

For those of you in the process of outfitting a new or future lab, a new hardware option is available with visible light imagers. FACIT -- Formulatrix Advanced Contrast Imaging Technology -- allows you to control the illumination pattern on a drop in order to see more crystal facets. Any light pattern can be projected onto a drop, including top-left, top-right, bottom-left, bottom-right, darkfield, and brightfield illumination. For more information, see FACIT.

Illumination options

64-Bit compatibility. Rock Imager now supports 64-bit computing for Windows 7 and newer. Due to lack of a suitable 64-bit camera driver, and best efforts to resolve subsequent technical issues, the only way for us to offer 64-bit compatibility is if you decide to purchase a new camera -- which we purchase from a different vendor -- for your imager. Please contact your sales rep for a quote.

Improved Drop Location. Behind-the-scenes configuration changes provide you with increased drop location detection accuracy.

System usage charts in the Imager Event Log. The Imager Event Log now includes a chart to provide visual feedback about how the imager is being used. You can choose from Plate Type, User Name or Group for the X-axis; the Y-axis displays Usage in Hours. The chart can be saved as an image and data can be exported to Excel. If you have Rock Imager with multiple light paths, you can further organize data by light path. For example, if you have visible and SONICC, your data will be separated into SONICC and visible categories.

Imager Event Log with Chart

’Capture Profiles’ renamed to ‘Imaging Settings’. In the interest of making Rock Imager and Rock Maker easier for new researchers to use, we’re saying goodbye to capture profiles. While the functionality stays the same, you’ll see the phrase ‘Imaging Settings’ in its place throughout the Rock Imager and Rock Maker programs.

Windows 8 compatibility. Rock Imager is ready to upgrade to Windows 8 when you are.

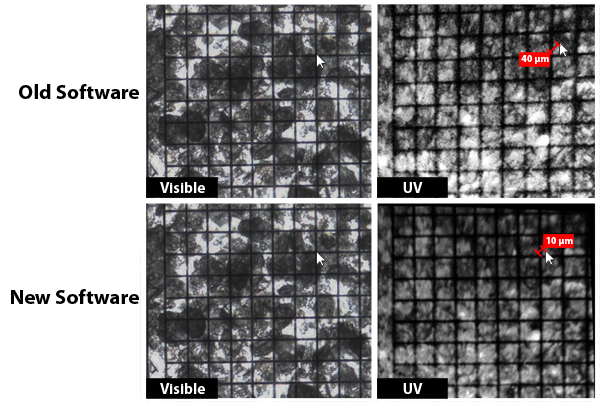

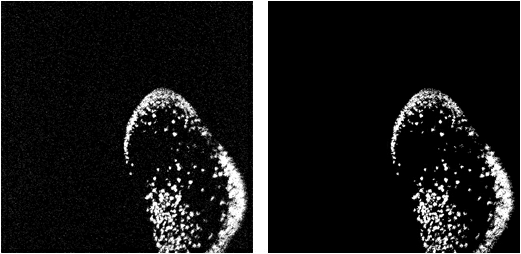

See more microcrystals in UV EFI images. We’ve tweaked some behind-the-scenes settings so that small crystals hidden in dense precipitant are now less likely to be missed when reviewing images. As you can see in the example images below, tiny crystals show up in the new image, but are “smoothed out” and lost in the old image.

Sitting drop before UV EFI improvement

Sitting drop after UV EFI improvement

Extended SONICC photomultiplier tube (PMT) life through smarter software. If Rock Imager detects too much signal during UV-TPEF or SHG imaging, imaging will automatically stop in order to protect the photomultiplier tube sensors, extending the life of your SONICC imager. If you are using SONICC in manual mode, a message will appear asking you to reduce the laser power. If SONICC is running in automatic mode, the drop producing too much signal will be skipped. If three drops are skipped in a row, then the plate will be skipped for that imaging setting.

Additional control over images with a new gain setting. We’ve added new controls to the Rock Imager software so that you can adjust the signal to noise ratio in your images. Previously, gain was set through the configuration files to a default of 5%. You can now lower the threshold if desired, which is beneficial in situations where a drop’s contents generate very-low voltage signal. However, you should expect to see more noise in your images. If you increase the threshold, your images will show less noise, but you sacrifice signal from the drop.

Gain setting

Increased Autoscoring accuracy. We're actively working to improve autoscoring for UV/SONICC images. Automatic scoring is a difficult area to perfect. We've taken your feedback about UV/SONICC autoscoring and made some configuration changes. Please continue to give us your feedback so that we can continue to improve this feature!

Smarter imaging. You will now be asked which “slot” to image before your imager starts imaging plates without barcodes, saving time and making the software more intuitive. In each imager, slot 1 is on the left and slot 2 is on the right.

Rock Imager 2.11 includes several enhancements to existing features that will make your work easier, as well as image improvements for UV customers, faster plate imaging for Rock Imager 1000 Dual Imager customers due to optimized plate handling, and a faster startup time for SONICC Benchtop customers. Formulatrix engineers have also made 27 other changes that won't be obvious to you, but change behind-the-scenes operations for a better overall experience. If you're curious about these additional changes, go to the website to view the latest release notes.

‘Image Interesting Drops’ from anywhere! Previously, imaging interesting drops required that the plate containing the interesting drops was already at the imaging station. Now, you can find the plate as you normally would, and execute the Image Interesting Drops command from the right-click menu. Rock Imager will move the plate to the imager at the earliest possible time and image your drops. For more information, see Imaging Interesting Drops.

See the imaging method for future imaging sessions on the Scheduling tab. We’ve added an ‘Imaging Mode’ column to the Scheduling tab, so you can now more easily see not only when a plate is scheduled to be imaged, but how the plate will be imaged. For more information, see Scheduling Tab.

See how many images RIP is waiting to process. Rock Imager Processor now tells you how many images are waiting to be processed, giving your more insight into behind-the-scenes operations -- and helping you figure out where your images might be if they’re not showing up in Rock Maker. For more information, see Rock Imager Processor. Click the image below to enlarge.

Clear drop locations -- and their overrides -- from Rock Imager. Now when you clear a drop location in Rock Imager, you will be asked if you also want to clear the drop location override created in Rock Maker -- if there is one. For more information, see Clearing Drop Locations. Requires Rock Maker 2.9.

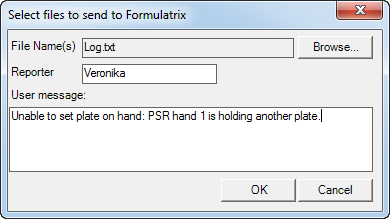

Include a note when you send log files to support. Sending log files to support to report a freeze or crash? Now you can type in a note to accompany the log file, so we have a better understanding of what you were doing when the incident occurred.

Behind-the-scenes license checks to keep your Rock Imager software current. Rock Imager now starts checking our servers for renewed license status 14 days before your license is set to expire. If a new license is found, Rock Imager will update your license automatically so that you don't miss any software updates. For more information about licensing, see Licensing.

Get your manually scheduled plates imaged, even if Rock Imager shuts down. In previous versions of Rock Imager, if the hardware or software shut down for any reason then manually scheduled plates were lost from memory. Now, Rock Imager remembers all of your manually queued plates, even if your hardware or software crashes, so your manually scheduled plates are still imaged the way you originally planned.

Better image contrast no matter the objective. Rock Imager now attempts to deliver the best contrast when imaging in UV by automatically matching the objective with a certain exposure time.

Faster imaging due to better plate handling. Plate handling has been optimized so that there is less downtime between plates -- while the first plate is imaging, Rock Imager will retrieve the next plate and wait for the first plate to finish. Then, it will retrieve the first plate from the imaging station, put the second plate in its place, and return the first plate to its storage location. Meanwhile, imaging has already started on the second plate.

Faster startup time. The startup sequence for SONICC Benchtop has been optimized so that you can begin using the Rock Imager software while the SONICC laser is warming up. If you attempt to engage the laser for imaging purposes before it is ready, a counter will appear displaying how much more time is needed before SONICC imaging can begin.

Rock Imager 2.10 is a major point release that introduces organizational interface changes, additions to the Plate Configuration page (now called the Plate Type Editor), several enhancements to both the SONICC and FRAP imaging processes, and more. Keep reading to learn about each of the changes.

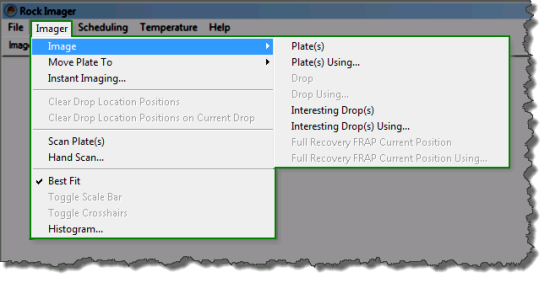

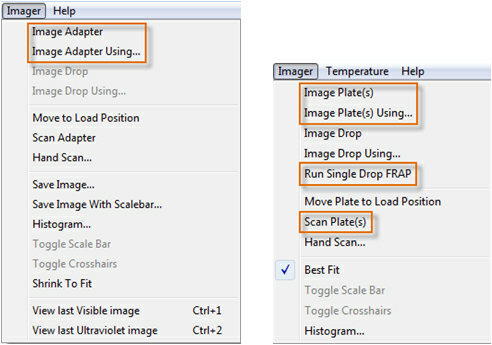

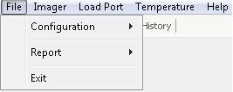

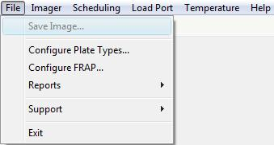

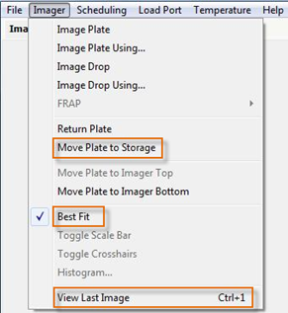

New Imager Menu. Various options from the Imager menu have been consolidated into the new Image sub-menu, as shown in the screenshot below.

Added the ability to image Interesting Drops. Once you’re running Rock Maker 2.8, you will have the ability to tag certain drops as interesting using the “i” key while viewing images in Rock Maker. You can then choose to image only interesting drops from the Rock Imager software, saving time and image disk space.

New Columns on the Scheduling Tab. If you have a dual imager Rock Imager 1000, the Scheduling tab will display two additional columns: Imaging Modes and Completed Imaging. The Imaging Modes column shows imaging methods that were scheduled for an imaging session, and the Completed Imaging column shows imaging methods that were successfully completed. If you are running an automatic imaging session using two imagers, the Imaging Modes column will display the imagers separately. Read more about the Scheduling tab.

Improved plate search. We have removed the need to search using “wildcards” – you can now simply type in your search parameters in the appropriate field and press the Enter key to search.

Easily identify plates that are stationed at an imager. If a plate is currently stationed at the imager, it will appear as highlighted in yellow on any Plates sub-tab (Scheduling, Search, Load Port). Further, we’ve added mouseover explanatory text that explains why a certain plate is highlighted, as shown below. This feature is available for all Rock Imagers except for Rock Imager 2 and Benchtop versions of SONICC and FRAP.

Plate Configuration renamed Plate Type Editor. Read more about the Plate Type Editor.

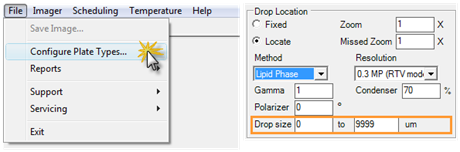

New Standard Drop Locator field. The Standard Drop Locator field allows you to specify settings related to the number of pixels that should be included in a drop, the aspect ratio, and more.

New Export button. You can now click an Export button to capture your plate settings and save them as an *.xml file. You can then edit the plate definition file in a text editor, rename it, save it, and import it as a new plate definition file using the Browse button next to the Plate Definition field.

Enhanced Drop Tuning for SONICC users. The Plate Type Editor has been modified to include a Capture Tuned Drops button, so you can define drop positions with the visible imager, overlay the visible image from each drop position on top of the SONICC live image, and use them as a tuning reference (Dual Imager SONICC only). Read more about drop location tuning.

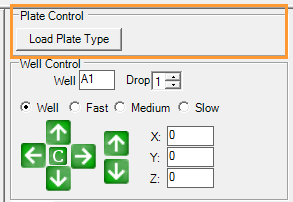

Editable Drop Position Coordinates. The X, Y, and Z fields in the Drop Position area are now editable, which means you can input exact drop positions instead of having to use the manual well and drop controls to define drop locations.

New Laser Camera Control. A new field has been added to the Camera Control panel allowing you to amplify or reduce the power of the laser at will, expressed as a percentage of maximum power. Read more about camera controls.

Laser automatically turns off when idle. To prevent thermal decomposition to samples, the SONICC laser will now automatically turn off after a specified idle period during manual inspections.

SONICC arm automatically retracts upon software shutdown. If you exit the Rock Imager software, SONICC will retract its arm to ensure that the plate door is closed when not in use.

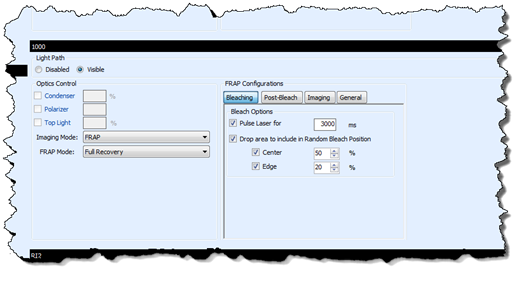

FRAP Configuration menu improvements. The FRAP Configurations dialog box has been simplified to make setting bleach options, full recovery and high throughput imaging options, and curve-fitting options easier. Read more about FRAP configuration.

Improved FRAP Capture Profiles. Additional Capture Profile settings are available in Rock Maker 2.8, granting you more control over your imaging sessions from the Rock Maker side.

Improved curve fitting algorithm. FRAP curves are now generated more accurately based on improvements to the curve algorithm.

Ability to use both Center and Edge bleach spots. You can now choose to select both a Center and an Edge bleach spot when imaging drops.

Improved setting of Bleach Position Locator. You can adjust specific drop intensity threshold value toward the bleach spots in the FRAP configuration. Read more Configuring FRAP General Options (Full Recovery only).

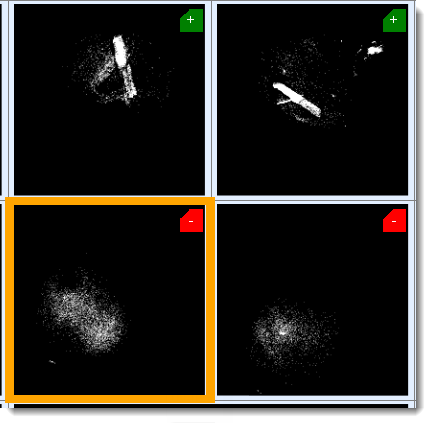

With Rock Imager 2.9, your time spent reviewing images that show empty wells and drops without crystal growth is coming to an end. Based on proprietary algorithms around image intensity, sharpness, edges, and objects, Rock Imager now categorizes each Ultraviolet, UV-TPEF or SHG image as a positive or negative hit. Using this feature, you can choose to filter your images for only positive hits or both positive and negative hits in Rock Maker.

The examples below are UV-TPEF images acquired with a SONICC imager. Mousing over the score in Rock Maker displays basic information about the score's origin, e.g. "UV-TPEF Auto Score: Positive Hit".

You can also filter the Canvas view to show only drops with positive hits from each imager, or drops with a positive hit from any imager. For more information about these capabilities, please see the Rock Maker help file.

Based on initial results, our algorithm yields less than 2 % false negatives and less than 8 % false positives. We hope to continually improve our detection algorithms for better accuracy with your help.

| Auto Scoring Accuracy | |||

|---|---|---|---|

| Image Type | Number of Samples | False Positives (%) | False Negatives (%) |

| Ultraviolet | 563 | 8 % | 2 % |

| SONICC SHG | 288 | 2 % | 0 % |

| SONICC UV-TPEF | 576 | 7 % | 0 % |

Note: You must be using Rock Maker 2.7 to view auto scores.

Image Masking can be used to hide fluorescence that appears around the edges of certain plate types containing specific materials. By hiding irrelevant fluorescence, plate masks reduce the probability of a false positive and increase the accuracy of Rock Imager’s auto score capability.

To learn about how to use image masks, see Applying Plate Masks.

To complement the autoscoring feature, some options have been added to ImagerLink.

Stay up to date with the latest versions via automatic update. Rock Imager can check for new releases at start up, or you can manually initiate a check at any time from the Help menu.

Camera offsets are now calibrated at four different locations instead of one, resulting in more accurate image overlays between Visible and UV or SONICC images. Support must change some settings to utilize this feature, so please contact us if you find that your offsets between visible and UV are off.

You can now image a plate without first having to set up an experiment in Rock Maker by selecting Load Plate Type from Plate Control or Instant Imaging from the Imager menu.

Experiments can be generated directly from Rock Imager with a new feature called Instant Imaging, available from the Imager menu. You can image an entire plate or a few select wells. Rock Imager Processor will send the images to Rock Maker. (Requires Rock Maker 2.6.)

Read more about Instant Imaging

The status bar now conveys information about whether RIP is on or off. RIP should always be running to ensure that images are passed over to Rock Maker. Notification emails are also sent out to warn you that RIP is not running.

You can now search for plates by their barcodes.

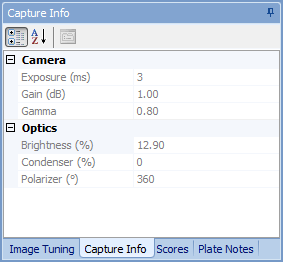

Capture profile information is now available through a new Capture Info Tab in Rock Maker, which is especially useful for images taken manually (available in Rock Maker 2.5).

Imager Link changes are of interest only to customers who integrate their own LIMS systems to Rock Imager. These changes are optional, Rock Imager will be backwards compatible to your old implementations if you choose to ignore these.

Read more about the ImagerLink API.

If there is a power failure and your imager switches over to an alternative power supply, the laser will automatically shut down after a set period of time to prevent damage.

You can now locate an area of interest in visible light and then instruct Rock Imager to show you the same area with the SONICC imager (manual imaging only).

You can now set the size of the image through the Zoom control or the new FOV control and the opposite control will automatically populate with the correct values.

Running multiple RIP applications to keep up with image processing tasks? RIP has been modified to meet high processing demand eradicating the need for multiple applications.

LCP drops lying at the edge of a precipitant are now located by Rock Imager's new algorithm. The size of the drop can be specified in the plate configuration page to make the algorithm more accurate. See the example images below for visual representations of old versus new LCP drop location algorithms.

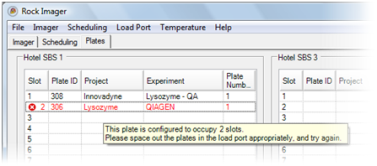

Warning messages will now alert you to leave two slots open for Qiagen plates to prevent plate crashes due to different plate dimensions.

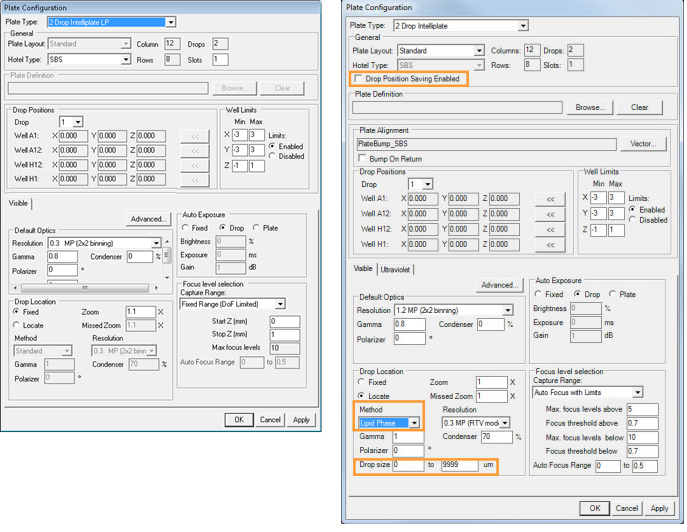

The plate configuration dialog box has been updated to reflect the latest algorithm and software changes.

|

|

| Before | After |

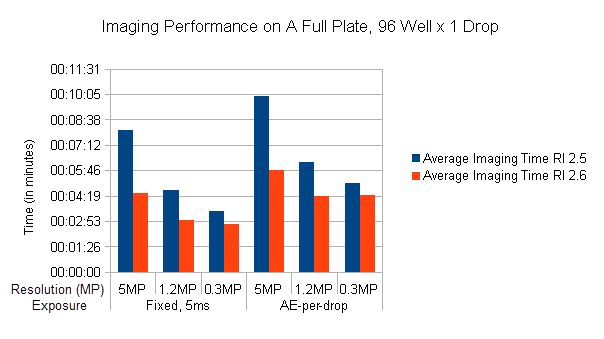

We have made changes "behind the scenes" to optimize imaging time resulting in a 40% time decrease for 5 MP imaging with Fixed or Auto Exposure brightness settings. 1.2 MP imaging time has decreased by 35%. See the following chart for performance improvement data.

Note: The imaging time varies from plate to plate; results vary depending on plate type, camera exposure, resolution and Max Focus settings.

One of the ways we have reduced imaging time is by saving drop location to memory, so the imager can skip that step on subsequent inspections. If you want the imager to define the drop location again, you can clear the drop location from memory on a per-well or per-plate basis on the Scheduling or Plates tab in Rock Imager.

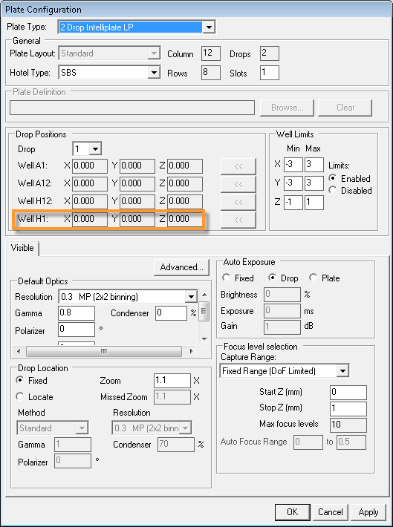

We have added a H1 drop location position for increased plate imaging accuracy. This change is backwards compatible with previous installs of Rock Imager. The new drop location position will be automatically calculated.

All system activities are display chronologically by default.

You no longer need to reset the exposure after you change the zoom when looking at your drop in manual mode. Laser power now automatically decreases when you zoom in, which is especially useful for ROIs.

The laser power and binning are automatically adjusted when the zoom level changes to provide optimal exposure settings. See the images below for reference.

The Extended Focus Imaging (EFI) algorithm system has been improved to reduce noise, see the images below for comparison.

| Before | After |

For more information, see Imaging with SONICC.

| Before | After |

In the Plate Information, the Group field displays the owner's group (as defined in Rock Maker -- Requires Rock Maker 2.2).

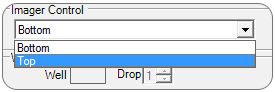

Rock Imager can now house two imagers. You can switch between the imagers using the new Imager control drop-down menu located on the right side of the user interface.

The imager options represent the imagers that are installed in the system. The rest of the imaging control will change based on which imager you select from the Imager Control menu.

In addition, two new options have been added to the Imager menu: Move Plate to Imager Top and Move Plate to Imager Bottom.

The Extended Focus Imaging (EFI) algorithm system used by Rock Imager has been improved in order to reduce noise in the resulting EFI. Below are some samples before (left) and after (right) images.

You can now view a report of system events that occur within a specific time period by using the Event Log, which can be found in the Reports menu under the File menu. The Event Log tracks:

Rock Imager now automatically backs up all configuration files as part of your database backups. If the imager PC crashes, you can quickly retrieve your backup configuration files. By default, Rock Imager will back up the configuration files once every two weeks.

Below are some Rock Imager menus before (left) and after (right) the changes.

|

|

|

|

While manually inspecting a plate, you can adjust the brightness and contrast of an image with the new Leveling Histogram. An auto-leveling feature processes captured images so that the same relative amount of leveling is performed on each image. The leveling histogram dramatically enhances UV images in the following ways:

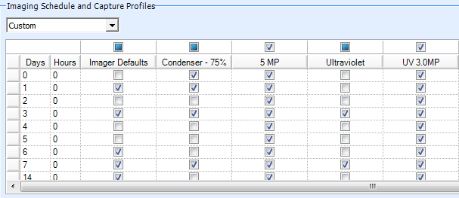

Rock Imager 2.3 optimizes your imaging schedule by allowing you to use different schedules for different capture profiles. For example, you can run Ultraviolet imaging on the third and seventh day only, as shown in the image below.

Rock Imager can now notify the owner of the plate via email whenever imaging is finished so that you can analyze your latest results.

Notifications are optional and can be sent according to a schedule that you specify. You can select between inspection notifications and digest notifications. Inspection notifications are sent a specified number of minutes after imaging is finished for each plate. Digest notifications are sent once a day and include a summary of daily events.

Notifications emails contain information about the plate’s inspection time, plate ID, barcode, location and current state.

Rock Imager can generate a report (in *.txt format) of all the plate types currently in use in the system. The list contains information about the plate type name, the plate definition (whether you used a reference plate when tuning the plate(s) in the system) and the plates' barcode.

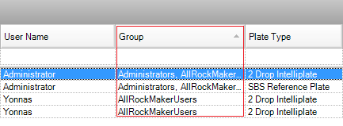

Rock Imager 2.3 allows you to analyze how different groups are using the imager with the Group column of the Plates tab. To see this column, you must have Rock Maker version 2.2 or newer.

Rock Imager Processor (RIP) will regularly notify you and the Formulatrix support team if you are running out of disk space (the notification is sent every 720 minutes by default). In the event that you run out of disk space completely, RIP will suspend itself and periodically check the disk space at a configurable interval. When space becomes available, RIP will automatically resume normal operation.

Rock Imager 2.3 allows you to manage the number of plates that can be loaded on each imager by assigning quotas to the groups. If a group’s limit is reached, Rock Imager will not allow additional plates belonging to that group to load. Group-based quotas are optional and require Rock Maker 2.2 or newer.

Rock Imager now supports Windows 7.

You can now copy the live view image using the copy command keyboard shortcut CTRL+C and paste into your favorite image editor using the paste command keyboard shortcut, CTRL+V.

Rock Imager 2.1.2 now supports authenticated SMTP email used for notifications.

To enable this configuration please set SMTPEnableSSL key in RockImager.config to True.

Users can now customize the order of plates in the load port either from top to bottom or vice versa. To enable this feature, set LoadPortStartLoading key in RobotServices.config to Top or Bottom (the default value is Top).

|

|

| RIC-V34R017 |