ROCK IMAGER 1000 is our most flexible imager, as it can house up to 1000 SBS-footprint plates or as many as 1500 glass LCP plates with an optional conversion. Plate capacity can also be limited to 250 SBS-footprint plates for more budget-conscious users and expanded if more room is needed at a later date.

ROCK IMAGER 1000 is sold as a single or dual imager. As a single imager, the load port is doubled in size and the visible imager (or visible and UV imager) is housed at the bottom of the chassis. As a dual imager, the visible (or visible and UV) imager is housed in the upper portion of the chassis, the load port is in the center, and a SONICC or FRAP imager is housed at the bottom of the chassis.

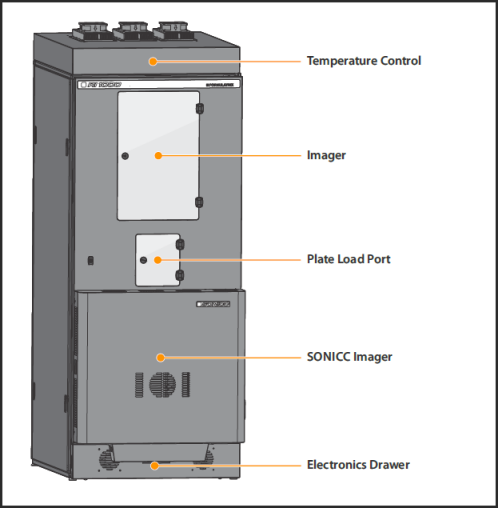

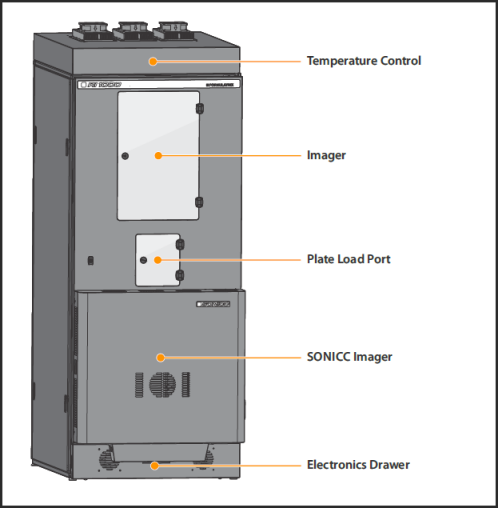

ROCK IMAGER 1000 External Components

The top portion of ROCK IMAGER 1000 monitors and regulates temperatures to within 0.1° C with the assistance of its air circulation system. The base model features a Peltier heat exchanger that regulates temperatures to 5° C below ambient to 7° C above ambient with 0.5° C precision.

Peltier enhanced panels can be added to cool the interior to 7° C below ambient. A redundant compressor can regulate temperature down to 4° C with an ambient temperature of 10° C to 30° C.

Dual compressors are available as an option to protect your imager in the event that a compressor fails.

ROCK IMAGER 1000 can include either SONICC, UV, or FRAP imaging modes in the base and a visible light imaging mode in the upper portion of the chassis.

The Load Port is where you load and unload plates. When you open the door, an internal door closes to protect the internal temperature and the load port shuttle automatically extends. You can also load entire multi-plate cartridges via the load port.

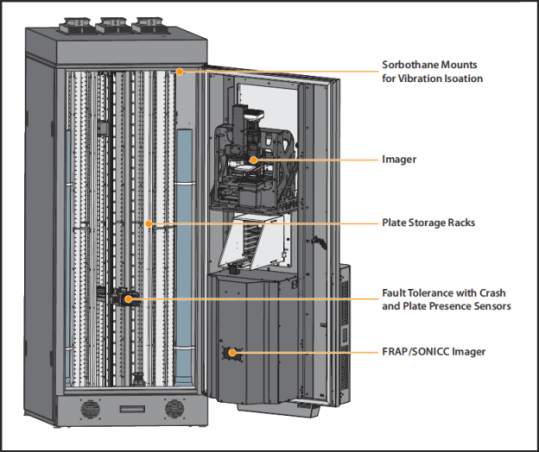

ROCK IMAGER 1000 Internal Components

Sorbothane mounts are used under the robot hands to reduce vibration caused by the robot's moving parts.

The plate storage racks are arranged radially within the back part of the ROCK IMAGER 1000 chassis. Plates are stored radially from the bottom up.

Crash sensors detect when a robot arm collides with something during regular operation. In the event of a crash, all operations will cease until the user corrects the problem in order to protect your plates from damage. Usually, plate crashes are caused by unintentional user error, such as leaving a plate lid on a plate.

The plate presence sensor detects situations where a plate may fall off of a robot hand. This can be caused by inadvertently forgetting to take tape off of a plate.

To protect your plates from damage, if an event trips the plate presence sensor, the imager will cease operations until the user addresses the issue.

|

|

| RIC-V38R119 |