Open topic with navigation

Adding Plate Types to the Plate Type Library

Four plate definitions come packaged with the TEMPEST for your convenience, but you may need to add additional plate definitions depending on the types of plates you use. To add a new plate to the TEMPEST plate database, follow the instructions on this page.

Prerequisites

- You have the microplate data sheet that came with your new plate, or are able to accurately measure distances with calipers (not provided).

Note: You can use the keyboard keys to control the motion when adding or modifying plate types.

W: The key moves the TEMPEST reagent inputs backward along the Y Axis.

S: The key moves the TEMPEST reagent inputs forward along the Y Axis.

A: The key moves the TEMPEST plate holder left along the X Axis.

D: The key moves the TEMPEST plate holder right along the X Axis.

R: The key moves the TEMPEST plate holder upward along the Z Axis.

F: The key moves the TEMPEST plate holder downward along the Z Axis.

The TEMPEST is equipped with 96 fixed nozzles with 9 mm horizontal and vertical pitch. However, due to the TEMPEST being able to move along both the X and Y axes and having independent nozzle control (depending on unit configuration), the TEMPEST can dispense into plateware with virtually any well size and row/column pitch. The TEMPEST New Plate Type Wizard includes a graphical presentation of your plate, which is generated by taking into consideration the number of wells, row pitch, column pitch, plate height, and well width of your plate. This graphic will also show you the position of the nozzles above the plate wells, to help you adjust the nozzle positions if necessary.

If you want to add a new 96 well-plate to the plate library, please follow the instructions below under Adding a 96-well plate to your plate library.

If you want to add a new 24 well-plate to the plate library, please follow the instructions below under Adding a 24-well plate to your plate library.

If you want to add a new 384/1536 well-plate to the plate library, please follow the instructions below under Adding a 384/1536-well plate to your library.

If you want to modify an existing plate type in the plate library, please follow the instructions under Modifying an Existing Plate Type.

Adding a 96-well plate to your plate library

Adding a 96-well plate to your plate libraryFollow the instruction below to add a 96-well plate to your plate library.

To add a new 96-well plate to your plate library:

In the Tools menu, click Plate Type Editor.

Go to the File menu and select New to start the new plate type wizard.

Put your plate on the TEMPEST plate holder.

In the wizard, select 96 from the Number of Wells list.

Note: After you have selected the number of wells from the list, the TEMPEST software will automatically populate row pitch, column pitch, well width, and plate height with ANSI/SLAS standard values. Please check these values and modify them if necessary so that they match your microplate data sheet. To adjust the values proceed to step 5, or directly proceed to step 9 if you do not need to make any adjustments.

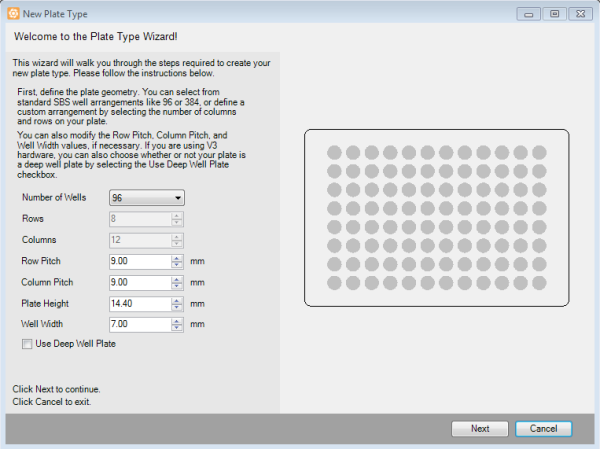

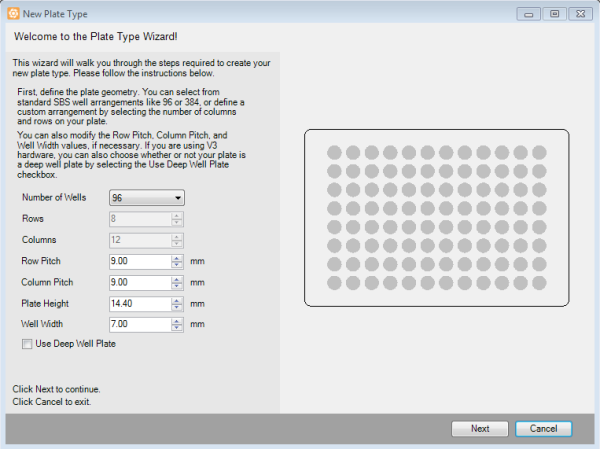

The Plate Type Editor Wizard

Type the Row Pitch in millimeters to define the distance between one well’s center point to another well’s center point in an adjacent row.

Type the Column Pitch in millimeters to define the distance between one well’s center point to another well’s center point in an adjacent column.

Type the height of your plate in millimeters in the Plate Height box. The Plate height value may vary from plate type to plate type. The default value for a standard plate is 14.40 mm, while the default deep well plate height is 44.0 mm. You can switch between these two defaults by selecting or clearing the Use Deep Well Plate option at the bottom of the screen. If you don’t have the plate height information available for your plate, you can overestimate the value and then adjust the dispense position later on.

Type the well width in millimeters in the Well Width box.

When you have finished, click Next to determine the A1 position. This position will be used by the software as the origin to calculate the well map during the subsequent steps.

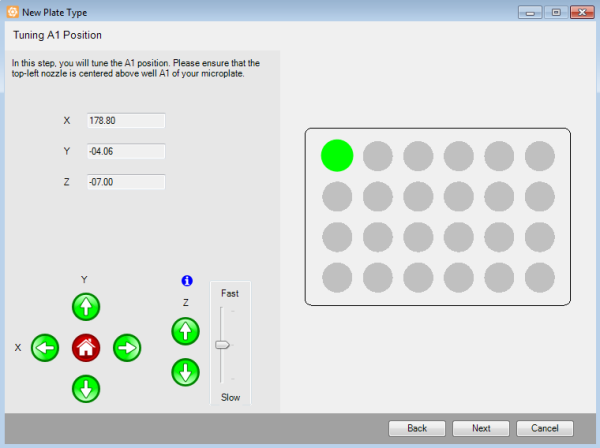

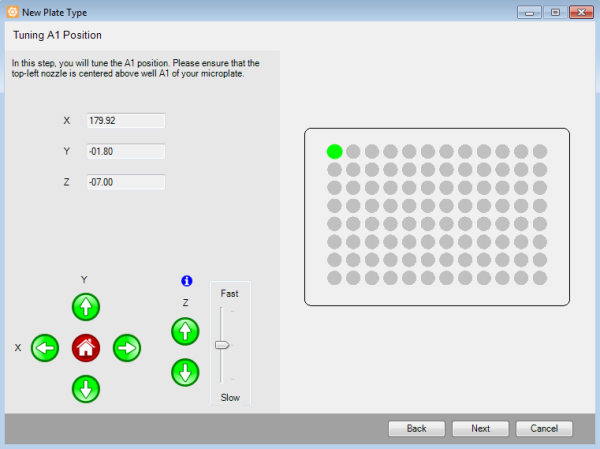

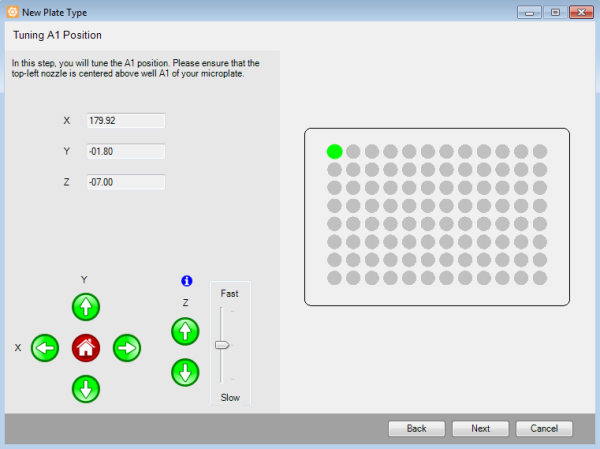

By using the Motion Control Pad, precisely move the Top-Left nozzle to the position above the A1 well (or equivalent) of your microplate. Visually inspect the nozzle to verify that it is accurately positioned over the center of the A1 well on the plate. Adjust the position if necessary.

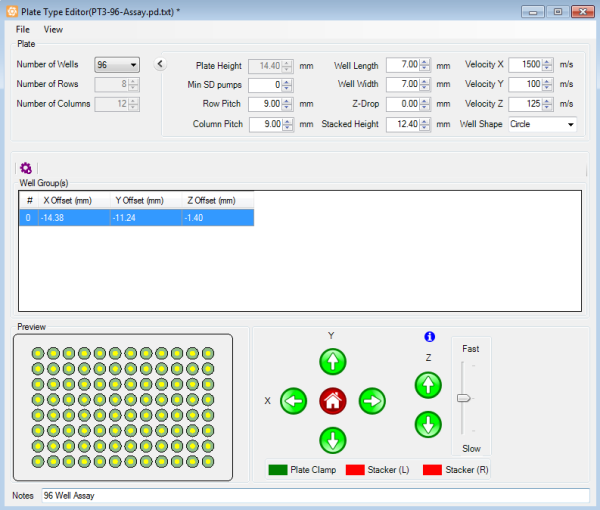

Tuning the A1 Position

- When you have finished, click Next to view or modify the generated positions.

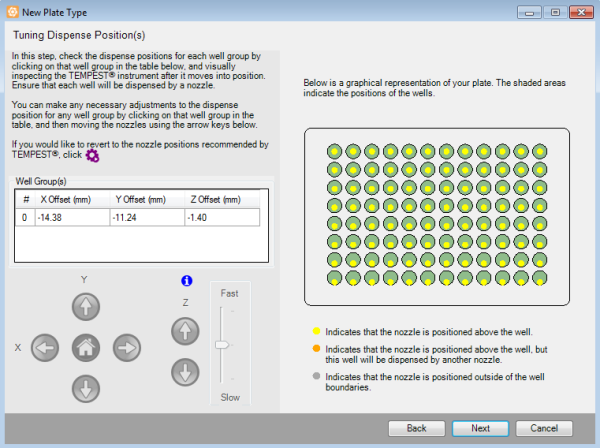

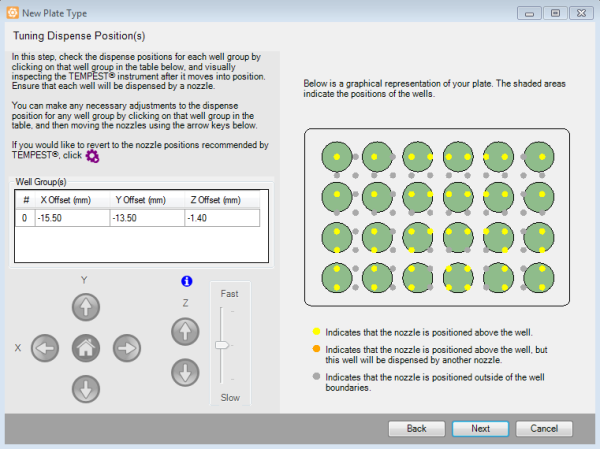

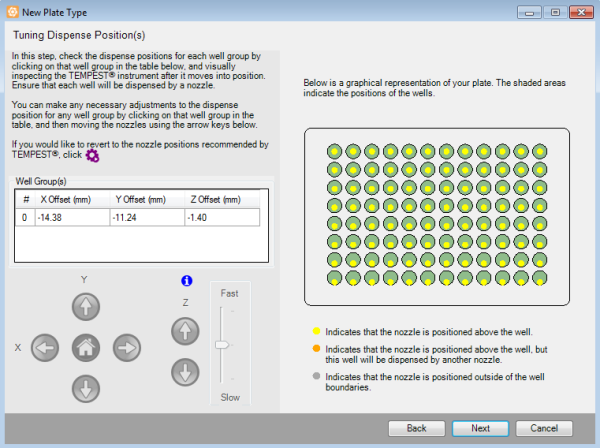

For a 96-well plate, the generated nozzle positions should be aligned with the wells, approximately 1 mm above the plate. The nozzles are represented in the wizard by yellow dots. Their position is shown relative to the well position and size, represented by green circles. These nozzle positions will be used to dispense into the wells. If they are not aligned, you can modify the X, Y, and Z values using the Motion Control Pad.

Tuning the Dispense Positions

If you are not satisfied with the results, click the Auto Generate button  to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

Click Next to proceed to the next step.

Type the plate name and then click Finish to save your plate definition.

Adding a 24-well plate to your plate library

Adding a 24-well plate to your plate libraryFollow the instruction below to add a 24-well plate to your plate library.

To add a new 24-well plate to your plate library:

In the Tools menu, click Plate Type Editor.

Go to the File menu and select New to start the new plate type wizard.

Put your plate on the TEMPEST plate holder.

In the wizard, select the 24 from the Number of Wells list.

Note: After you have selected the number of wells from the list, the TEMPEST software will automatically populate row pitch, column pitch, well width, and plate height with ANSI/SLAS standard values. Please check these values and modify them if necessary so that they match your microplate data sheet. To adjust the values proceed to step 5, or directly proceed to step 9 if you do not need to make any adjustments.

The Plate Type Editor Wizard

Type the Row Pitch in millimeters to define the distance between one well’s center point to another well’s center point in an adjacent row.

Type the Column Pitch in millimeters to define the distance between one well’s center point to another well’s center point in an adjacent column.

Type the height of your plate in millimeters in the Plate Height box. The Plate height value may vary from plate type to plate type. The default value for a standard plate is 14.40 mm, while the default deep well plate height is 44.0 mm. You can switch between these two defaults by selecting or clearing the Use Deep Well Plate option at the bottom of the screen. If you don’t have the plate height information available for your plate, you can overestimate the value and then adjust the dispense position later on.

Type the well width in millimeters in the Well Width box.

When you have finished, click Next to determine the A1 position. This position will be used by the software as the origin to calculate the well map during the subsequent steps.

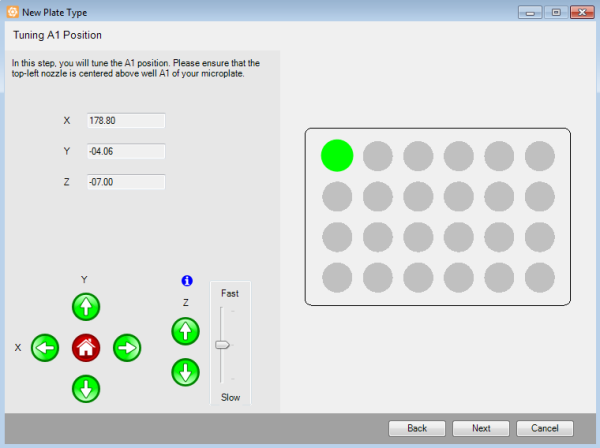

By using the Motion Control Pad, precisely move the Top-Left nozzle to the position above the A1 well (or equivalent) of your microplate. Visually inspect the nozzle to verify that it is accurately positioned over the center of the A1 well on the plate. Adjust the position if necessary.

Tuning the A1 Position

When you have finished, click Next to view or modify the generated positions.

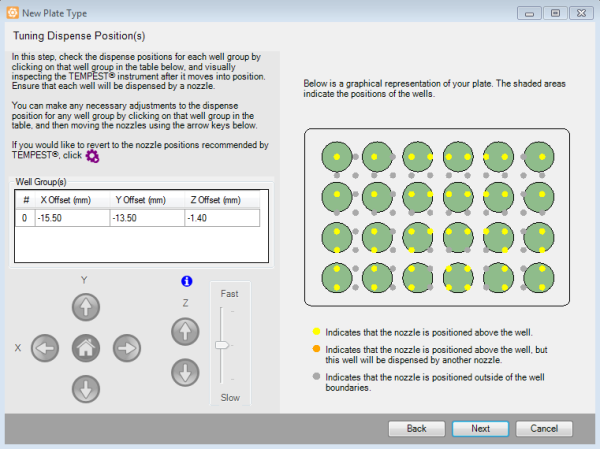

For a 24-well plate, the dispense position must be set so that each well can be dispensed by at least one nozzle, and the nozzles should be positioned approximately 1 mm above the plate. If necessary, you can modify the X, Y, and Z values using the Motion Control Pad. In the first image of the example below, the nozzle positions for well D4 are not completely inside of the well. The second image shows the nozzle positions after being adjusted, so that all of the wells can be dispensed by at least one nozzle.

The Nozzle Positions Before Adjustments

The Nozzle Positions After Adjustments

The nozzles are represented in the wizard by either yellow, orange, or gray dots, as explained below:

Yellow indicates that the nozzle is positioned above the well.

Orange indicates that the nozzle is positioned above the well, but this well will be dispensed by another nozzle.

Gray indicates that the nozzle is outside of the well’s boundaries.

If you are not satisfied with the results, click the Auto Generate button  to revert to the positions recommended by TEMPEST, and then adjust the positions as needed. Click Next to proceed to the next step.

to revert to the positions recommended by TEMPEST, and then adjust the positions as needed. Click Next to proceed to the next step.

- Type the plate name and then click Finish to save your plate definition.

Adding a 384/1536-well plate to your library

Adding a 384/1536-well plate to your libraryFollow the instruction below to add a 384/1536-well plate to your plate library.

To add a new 384-well plate to your plate library:

In the Tools menu, click Plate Type Editor.

Go to the File menu and select New to start the new plate type wizard.

Put your plate on the TEMPEST plate holder.

In the wizard, select 384 or 1536 from the Number of Wells list.

Note: After you have selected the number of wells from the list, the TEMPEST software will automatically populate row pitch, column pitch, well width, and plate height with ANSI/SLAS standard values. Please check these values and modify them if necessary so that they match your microplate data sheet. To adjust the values proceed to step 5, or directly proceed to step 9 if you do not need to make any adjustments.

The Plate Type Editor Wizard

Type the Row Pitch in millimeters to define the distance between one well’s center point to another well’s center point in an adjacent row.

Type the Column Pitch in millimeters to define the distance between one well’s center point to another well’s center point in an adjacent column.

Type the height of your plate in millimeters in the Plate Height box. The Plate height value may vary from plate type to plate type. The default value for a standard plate is 14.40 mm, while the default deep well plate height is 44.0 mm. You can switch between these two defaults by selecting or clearing the Use Deep Well Plate option at the bottom of the screen. If you don’t have the plate height information available for your plate, you can overestimate the value and then adjust the dispense position later on.

Type the well width in millimeters in the Well Width box.

When you have finished, click Next to determine the A1 position. This position will be used by the software as the origin to calculate the well map during the subsequent steps.

By using the Motion Control Pad, precisely move the Top-Left nozzle to the position above the A1 well (or equivalent) of your microplate. Visually inspect the nozzle to verify that it is accurately positioned over the center of the A1 well on the plate. Adjust the position if necessary.

Tuning the A1 Position

When you have finished, click Next to view or modify the generated positions.

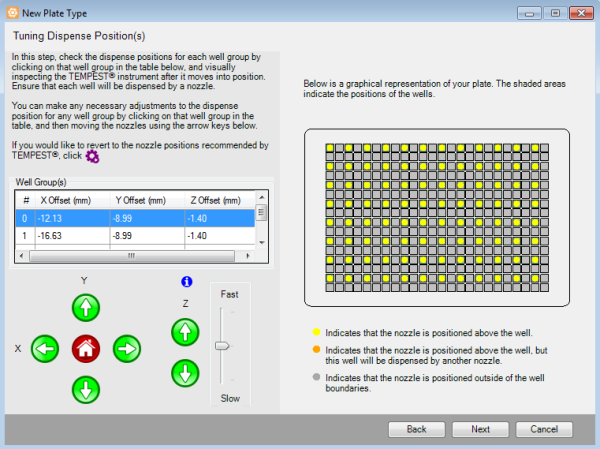

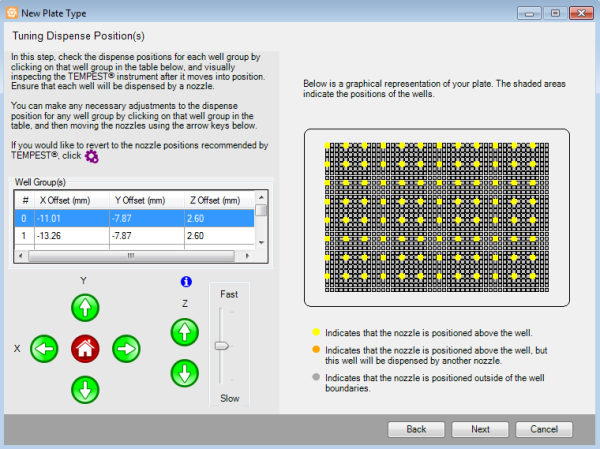

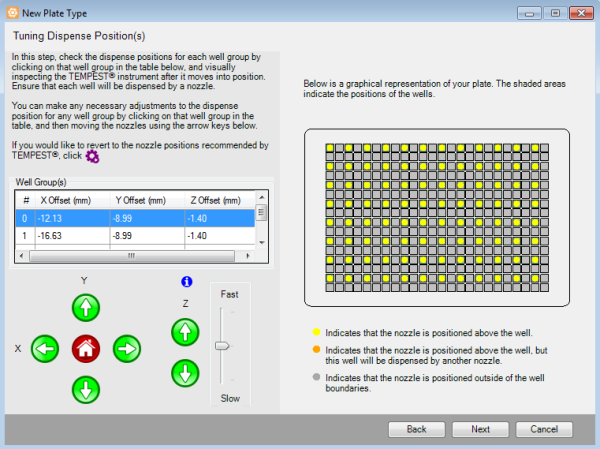

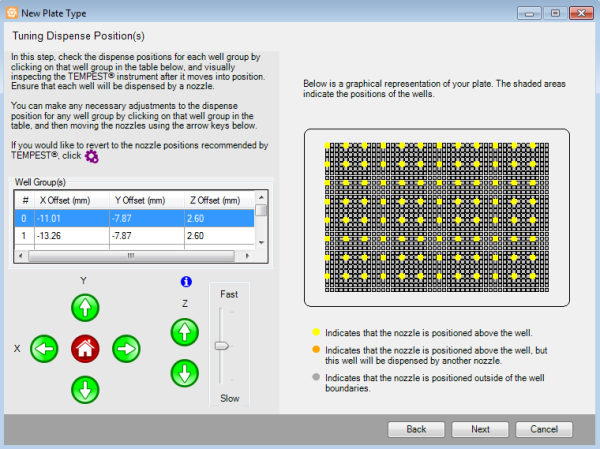

For a 384 or 1536-well plate, each of the generated nozzle positions should align with a subset of the wells, approximately 1 mm above the plate. A 384-well plate will have four different well groups of 96 wells (one for each nozzle), and a 1536-well plate will have 16 well groups. For example, Well Group 0 might include wells A1, A3, A5, A7, C1, C3, C5, C7, etc., whereas Well Group 1 includes wells A2, A4, A6, A8, C2, C4, C6, C8, and so on. TEMPEST ensures that each well on a plate is included in one of the well groups.

Check the nozzle positions for each well group to ensure that they are aligned with the wells. If they are not, you can modify the X, Y, and Z values using the Motion Control Pad. The nozzles are represented in the wizard by either yellow, orange, or gray dots, as explained below:

Yellow indicates that the nozzle is positioned above the well.

Orange indicates that the nozzle is positioned above the well, but that this well has already been dispensed by another nozzle.

Gray indicates that the nozzle is outside of the well’s boundaries.

A 384-well Plate Graphical Representation

A 1536-well Plate Graphical Representation

If you are not satisfied with the results, click the Auto Generate button  to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

Click Next to proceed to the next step.

Type the plate name and then click Finish to save your plate definition.

You have successfully added a new plate type in the Plate Type Editor. To learn how to modify the plate settings, go to the Modifying an Existing Plate Type section below.

Modifying an Existing Plate Type

Modifying an Existing Plate TypeOccasionally, you might want to modify the settings of an existing plate type in the TEMPEST plate type library. Follow these steps below to make adjustments to your plate type settings.

Prerequisites

- You have existing plate type settings that you wish to modify.

To modify an existing plate type:

Open the Tools menu and click Plate Type Editor.

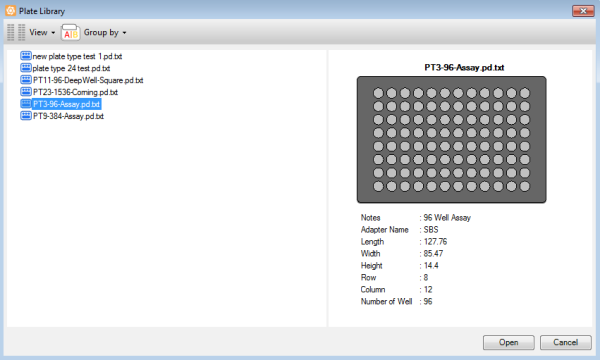

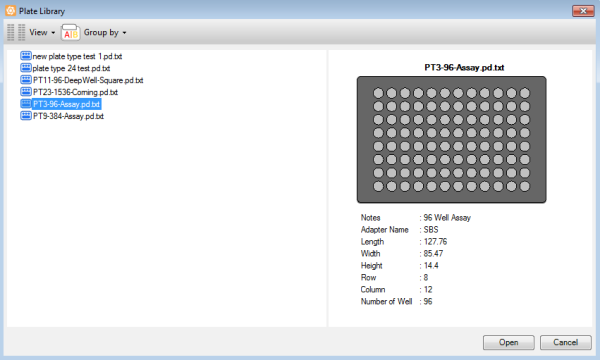

Go to the File menu, click Open, then select a plate type and click Open again. The details for the plate you chose populate the Plate Type Editor.

The Plate Library

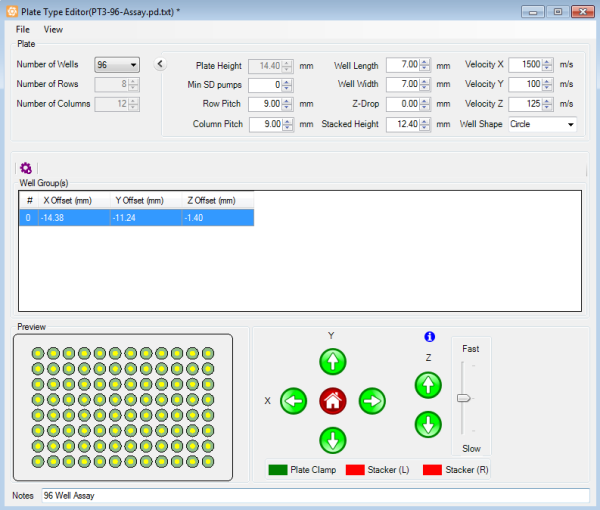

Type the height of the plate in millimeters in the Plate Height option.

Type the minimum number of small diaphragm pumps to be used in the Min SD Pumps option. This setting forces the TEMPEST to use the Small Diaphragm for a larger portion of the dispense, if possible. For example, when you use a High Volume chip to dispense 10 µL and your Min SD Pumps number is 5, TEMPEST will dispense 5 cycles using the Small Diaphragm and 1 cycle using the Large Diaphragm. For more information, see TEMPEST Chip Specifications.

Note: This feature is useful for preventing splashing that can occur when dispensing into round or conical bottomed plates. If splashing occurs when dispensing into your plate, setting this number to 5 or higher will greatly reduce or eliminate the splashing.

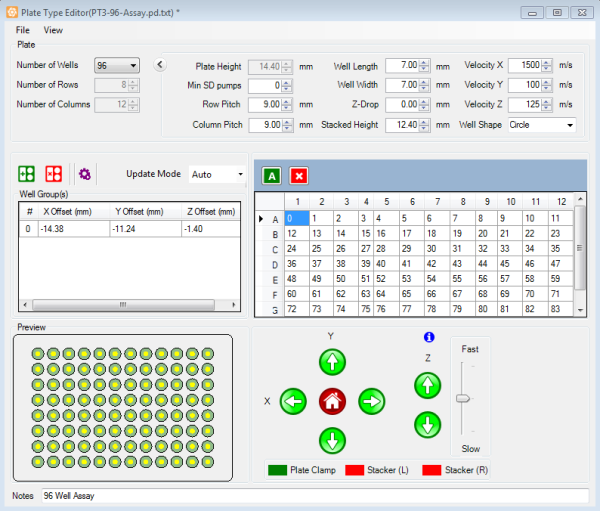

The Plate Type Editor

Modify the necessary parameters by clicking the Show Advanced Options menu.

Row Pitch determines the distance between one well’s center point to another well’s center point in an adjacent row, in millimeters.

Column Pitch determines the distance between one well’s center point to another well’s center point in an adjacent column, in millimeters.

Well Length determines the length of the well in millimeters.

Well Width determines the width of the well in millimeters.

Z-Drop determines the distance that the nozzle is lowered inside of the well before dispensing, in millimeters. This feature is useful to minimize reagent splashing. The default value is zero. Please note that setting the Z-drop to a value larger than the sum of the nozzle length and the distance between the nozzle and the top of the plate will result in the plate crashing into the chips.

Stacked Height determines the height of the plate in millimeters, after it is stacked with other plates when you use the plate stackers. The height can be calculated by measuring the height of two identical plates stacked and subtracting the height of a single plate (Plate Height). If you change the Plate Height value in the Plate Type Editor, the stacked height value will be updated automatically.

Velocity X determines the movement speed along the X axis. The default speed is 1500 m/s. Please note that while this default speed is safe for plates with 96 wells and more, you may find it necessary to decrease the velocity for plates with larger, more shallow wells to avoid spillage during movement.

Velocity Y determines the movement speed along the Y axis. The default speed is 100 m/s.

Velocity Z determines the movement speed along the Z axis. The default speed is 125 m/s.

Well Shape determines the shape of the well, whether it is circular or rectangular.

Put your plate on the TEMPEST plate holder.

Optional: By using the Motion Control Pad, modify the X, Y, and Z values for each row to position the wells under the nozzles. The nozzles should be positioned over the center of the wells, approximately 1 mm above the plate. If you are not satisfied with the results, click the Auto Generate button  to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

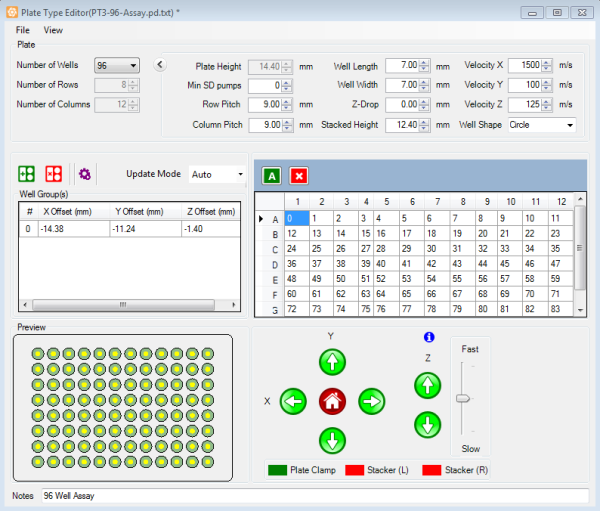

Optional: Go to the View menu and select Advanced to modify the dispense positions manually or automatically.

The Advanced view allows you to change the well group update mode and change the nozzle/well assignment.

Important: The nozzle/well assignment option is for advanced users only and is not covered in this document. Please contact support@formulatrix.com if you require assistance.

Advanced Settings in the Plate Type Editor

The default update mode is Auto. It’s behavior is identical to non-advanced mode of the plate type editor. It applies any changes made to a single well group’s origin coordinates across all other well groups.

For plates with multiple well groups and non-standard layouts you might find it necessary to adjust the well group coordinates individually. Follow the instructions below to manually adjust the coordinates:

Select Manual in the update mode list next to the Auto Generate button  .

.

Select the well group you would like to adjust. The TEMPEST will move to the currently specified coordinates.

Use the Motion Control Pad or the keyboard keys to fine-tune the plate position under the nozzles. The nozzles should be positioned over the center of the wells, approximately 1 mm above the plate. Please note that in manual update mode each well group has to be adjusted individually, and you will need to repeat the process for all of the well groups you wish to modify. If you are not satisfied with the results, click the Auto Generate button  to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

When you have finished, proceed to step 9.

Go to the File menu in the Plate Type Editor window, and click Save (Ctrl+S) to save your changes.

Related Topics

|  |

| TEC-V32R219 | |

to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.

to revert to the positions recommended by TEMPEST, and then adjust the positions as needed.