It is possible to programmatically build a full MANTIS dispense list with every possible variable. This can streamline automated workflows by removing the need to manually define your dispense list or import data from a .CSV file. Read the description in the table for more detailed information, and pay close attention to the formatting.

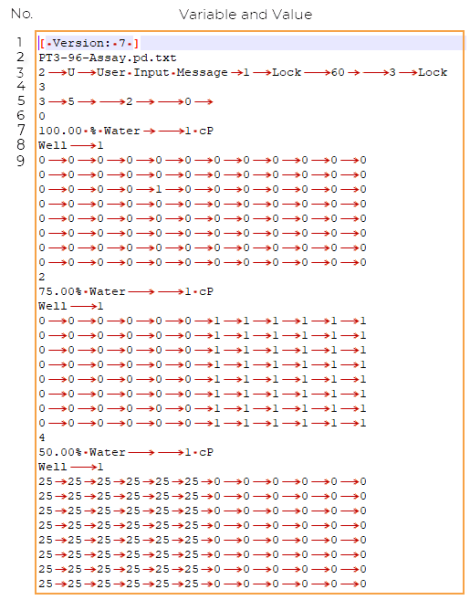

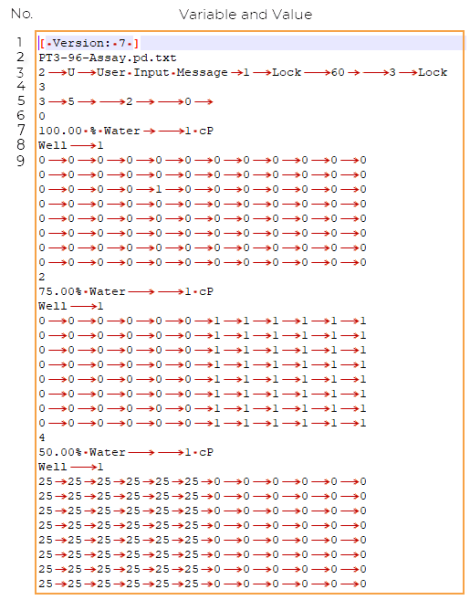

The Dispense List File Format Sample

Legend:

● Space

→ Tab

| No. | Variable | Description | Acceptance Value |

|---|---|---|---|

| 1. | Version |

Version of dispense list parser within the MANTIS software. Each MANTIS software version comes with a parser version. The current dispense list parser is compatible with the previous versions, but we recommend upgrading the software to accommodate the parser to read the dispense list accurately. |

Dispense list parser version (file format) |

| 2. | Plate Type Name | The name of the plate to be used in the dispense. | Plate type file name |

| 3. | Delays | Defines the delay settings assigned in the dispense. Each delay setting is separated by a tab, and multiple delays within a single dispense are appended to this line. See the dispense list file format sample. |

Note: The sample above uses UserInput (1) and Timer (2) delay types. Follow the delay setting codes accordingly:

Settings for UserInput delay (first delay in the file format sample)

Settings for Timer delay (second delay in the file format sample)

|

| 4. | Number of Plates | Specifies the number of plates to be dispensed. It’s typically used for running a multi-plate dispense with single dispense list. | Number of plate(s) |

| 5. | Delay Between Wells Per Reagent | Number of reagents to be dispensed followed by the delay time between wells for each reagent. |

Follow the reagent and delay code accordingly (from left to right):

(Delay time for each reagent)

|

| 6. | Reagent Location on Dispense List | Defines the reagent’s position in the dispense list. | Reagent’s position, starting with 0. |

| 7. | Reagent Name and Viscosity | Name of the reagent and its viscosity to be used in the dispense. | Reagent name and viscosity |

| 8. | Dispense Location | Specifies the dispense location followed by its index. |

|

| 9. | Well Designer | Defines the dispense volume in each well. | See the dispense list file format sample. |

|

|

| MAOWH-V47R722 |