MANTIS is able to dispense liquids with a wide variety of viscosities. To ensure accurate dispense volumes, especially viscous liquids require different settings than those that are used for less viscous liquids. The MANTIS Liquid Classes feature allows you to sort your reagents into different groups by viscosity, and give each group its own delay and pressure/vacuum settings for optimal dispense performance.

MANTIS comes with five liquid classes by default, 1 cP, 2-5 cP, 6-10 cP, 11-20 cP, and 21-25 cP each of which comes with its own optimized dispense settings. You can also create new liquid classes with customized settings for particular reagents.

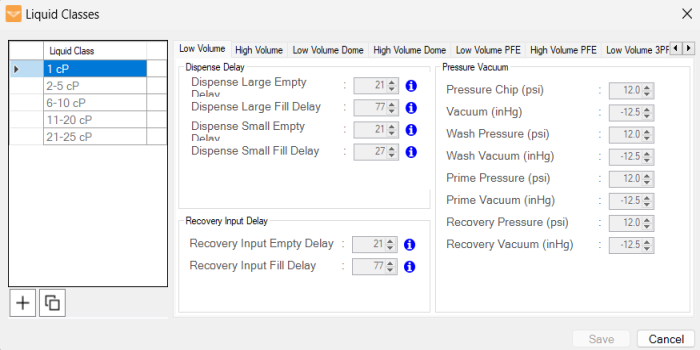

MANTIS Liquid Classes Menu

The Liquid Classes menu consists of 2 main panels: the Liquid Class column and the Chip Settings tabs. The Liquid Class column contains a list of all available liquid classes in your MANTIS. In the Chip Settings tabs, you can set the Dispense Delay, Recovery Input Delay, and Pressure Vacuum settings for each silicone or 3PFE chip type. The available settings for your chip type are as follows:

Important: Do not adjust the below settings for PFE chips. It is recommended to use silicone or 3PFE chips to dispense viscous reagents. For more information about chemical compatibility with FORMULATRIX chips, click here.

There are five liquid classes with the default settings available in MANTIS:

Important: When you create a new liquid class, it is strongly recommended to set the delay and pressure vacuum values to fall within the range defined by the default MANTIS 1 cP, 2-5 cP, 6-10 cP, 11-20 cP, and 20-25 cP liquid classes. Using values that are out of range may affect the accuracy and precision of the dispense. For more information, see .

Important: The delay and pressure/vacuum settings for the MANTIS default liquid classes cannot be modified or deleted. You will need to create a new liquid class to modify these settings. You can copy the default settings to a new liquid class, and adjust the settings as needed. For more information, see Creating a Liquid Class.

Under the Liquid Class column, you can also access the following buttons:

— The Add button allows you to add a new liquid class.

— The Duplicate button allows you to duplicate the selected liquid class.

— The Delete button removes the selected liquid class.

| Option | Description |

|---|---|

| Dispense Large Empty Delay (ms) | Determines the length of time in milliseconds that the large diaphragm will be closed while the chip is being emptied during dispense. |

| Dispense Large Fill Delay (ms) | Determines the length of time in milliseconds that the large diaphragm will be open while the chip is being filled during dispense. |

| Dispense Small Empty Delay (ms) | Determines the length of time in milliseconds that the small diaphragm will be closed while the chip is being emptied during dispense. |

| Dispense Small Fill Delay (ms) | Determines the length of time in milliseconds that the small diaphragm will be open while the chip is being filled during dispense. |

| Option | Description |

|---|---|

| Recovery Input Empty Delay (ms) | Determines the length of time in milliseconds that the large diaphragm will be closed while the chip is being emptied during recovery. |

| Recovery Input Fill Delay (ms) | Determines the length of time in milliseconds that the large diaphragm will be open while the chip is being filled during recovery. |

The Pressure Vacuum settings allow you to customize the pressure and vacuum settings for each liquid class and for each chip type.

Important: It is strongly recommended to not make any changes to the MANTIS pressure and vacuum settings, unless directed to do so by FORMULATRIX support. Changes made to the MANTIS pressure and vacuum settings may adversely affect the accuracy of your dispense. A notification will appear in MANTIS if any dispensing problems occur due to issues with the pressure or vacuum.

| Option | Default Value for LV and HV Chip Type | Description |

|---|---|---|

| Pressure Chip (psi) | 12.0 | Determines the chip pressure used during dispense. |

| Vacuum (inHg) | -12.5 | Determines the air vacuum used during dispense, |

| Wash Pressure (psi) | 12.0 | Determines the air pressure used during a wash process. |

| Wash Vacuum (inHg) | -12.5 | Determines the air vacuum used during a wash process. |

| Prime Pressure (psi) | 12.0 | Determines the air pressure used when priming an input. |

| Prime Vacuum (inHg) | -12.5 | Determines the air vacuum used when priming an input. |

| Recovery Pressure (psi) | 12.0 | Determines the air pressure used during reagent recovery. |

| Recovery Vacuum (inHg) | -12.5 | Determines the air vacuum used during reagent recovery. |

Click the Reset button to reset all of the above values to their default settings.

|

|

| MAOWH-V48R824 |