Lubricating the O-rings

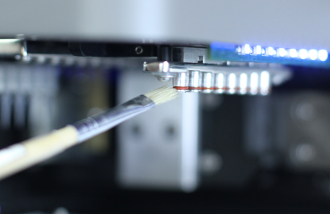

For NT8 V3 hardware only. The NT8 O-ring is a small red or black rubber circle (colors may vary depending on your NT8 series) on the NT8’s plate copy head that create air-tight seals around each of the eight nozzles.

Note: O-rings are only found on the plate copy head; if you did not purchase the Plate Copy option, you do not need to follow these instructions.

Note: If you are using NT8 V4 hardware, you no longer need to perform Plate Copy O-rings lubrication because the O-rings are now found in the HV tips themselves.

If you are noticing an aspirate or dispense volume problem when attempting to copy a plate, you should lubricate the O-rings as part of a troubleshooting effort. Otherwise, the O-rings should be lubricated every six months.

The estimated time required to grease the NT8 O-ring is 3 minutes.

Before you begin, please make sure that there are no High Volume tips attached to the NT8’s plate copy head.

Prerequisites

- The NT8 is powered off and unplugged.

What You Will Need:

- A small paint brush (shipped in your accessory kit).

- Grease (shipped in your accessory kit).

- A deep well block filled about half way with water colored with food dye.

- A daughter plate.

- A High Volume tip caddy with 8 HV tips.

Lubricating the O-rings

-

Open the hood to expose the NT8’s head and deck.

-

Using the paintbrush, lightly but evenly apply grease to the front and back of each of the eight O-rings on the NT8’s plate copy head.

Apply Grease to the O-Rings

-

When you are finished, power-on the NT8 and continue with Running a Plate Copy Test.

Related Topics

|

|

| NTC-V43R022 |