MANTIS can dispense liquids with viscosities up to 25 centipoise (cP) using the default liquid classes provided in the software. Working with high-viscosity reagents without properly assigning liquid class can cause inaccurate dispense volume, higher coefficient of variation (CV), and hanging drops.

Here are some commonly used reagents with viscosities approaching the top-end of the default liquid classes:

PEG 1000, 40%

PEG 3350, 28%

PEG 4000, 25%

PEG 8000, 18%

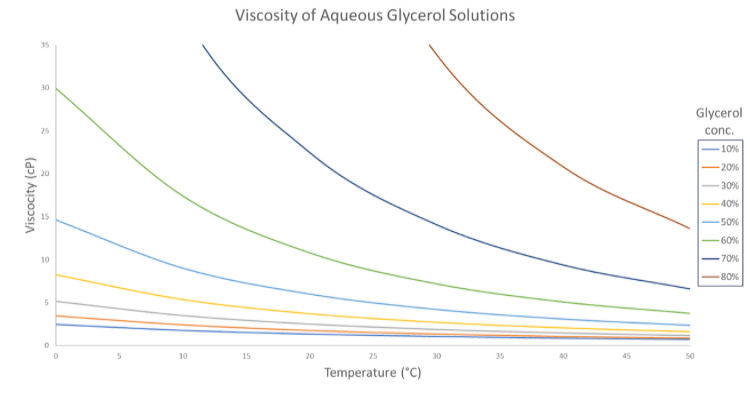

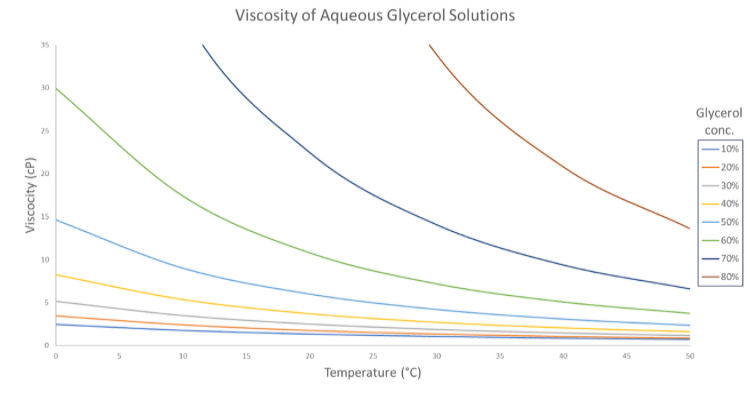

Use the following table and plot as a rough guide for liquid class selection.

| Viscosity of Aqueous Glycerol Solutions (cP) | ||||||

| Glyc % Wt. | Temperature (°C) | |||||

| 0 | 10 | 20 | 30 | 40 | 50 | |

| 0 | 1.792 | 1.308 | 1.005 | 0.8007 | 0.6560 | 0.5494 |

| 10 | 2.44 | 1.74 | 1.31 | 1.03 | 0.826 | 0.680 |

| 20 | 3.44 | 2.41 | 1.76 | 1.35 | 1.07 | 0.879 |

| 30 | 5.14 | 3.49 | 2.50 | 1.87 | 1.46 | 1.16 |

| 40 | 8.25 | 5.37 | 3.72 | 2.72 | 2.07 | 1.62 |

| 50 | 14.6 | 9.01 | 6.00 | 4.21 | 3.10 | 2.37 |

| 60 | 29.9 | 17.4 | 10.8 | 7.19 | 5.08 | 3.76 |

| 70 | 76 | 38.8 | 22.5 | 14.1 | 9.40 | 6.61 |

| 80 | 255 | 116 | 60.1 | 33.9 | 20.8 |

13.6 |

(taken from Physical Properties of Glycerine and Its Solutions (1963), p.10)

Viscosity of Aqueous Glycerol Solutions Graph

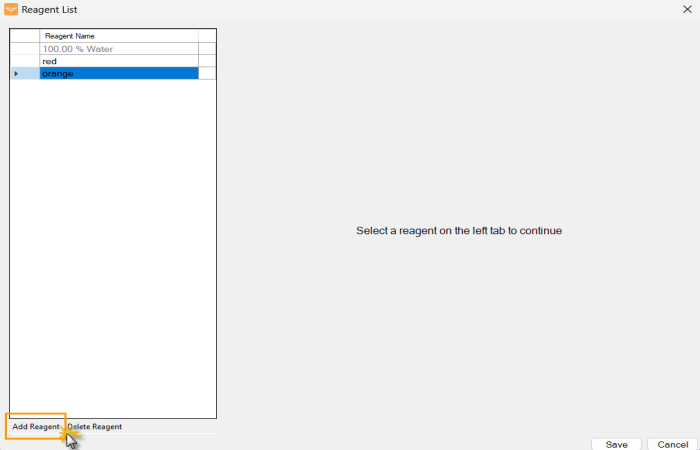

From the Tools menu, open the Reagent List window, and add a new reagent.

Create a New Reagent

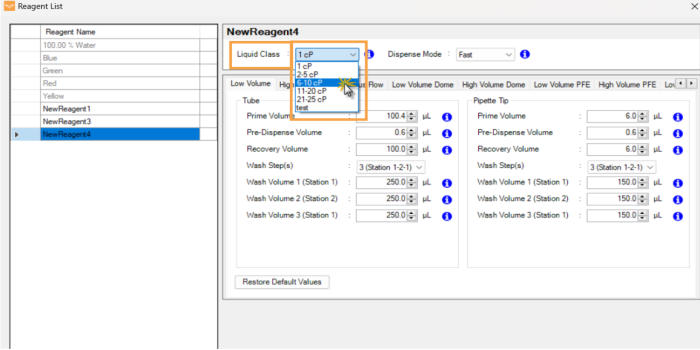

Select a liquid class based on your reagent viscosity from the Liquid Class dropdown selection at the right side of the Reagent Name list.

Selecting Liquid Class

Click Save to save the changes.

In the Reagent List window, select the reagent of your choice.

Choose the liquid class based on your reagent viscosity.

If your reagent is too viscous for the default liquid classes, you can create your own custom liquid classes with longer delay timings and higher pressures. For more information on creating custom liquid classes, see Creating a Liquid Class.

Note: Use of custom liquid classes may damage your chips and will impact performance. Chip specifications are not guaranteed when using custom liquid classes, and we recommend contacting support@formulatrix.com for assistance with this process.

For Continuous Flow (CF) dispensing, increase the Bottle Pressure value to help dispense viscous reagents. Each reagent might require a slightly different bottle pressure for optimal dispensing.

Note: You should recalibrate the CF chips whenever you change the bottle pressure. For more information on calibrating the CF chips, see Calibrating Continuous Flow Chips.

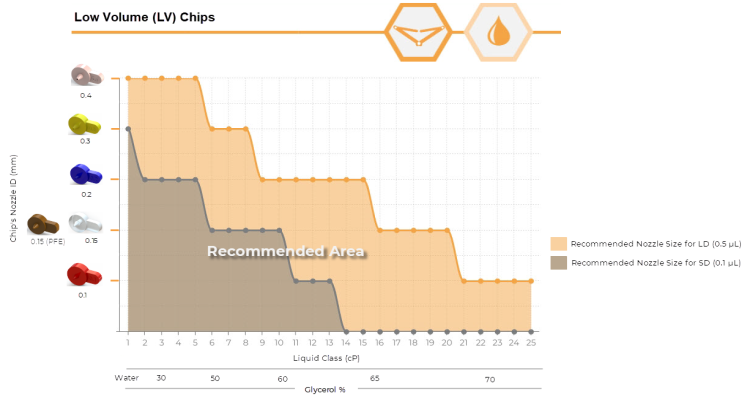

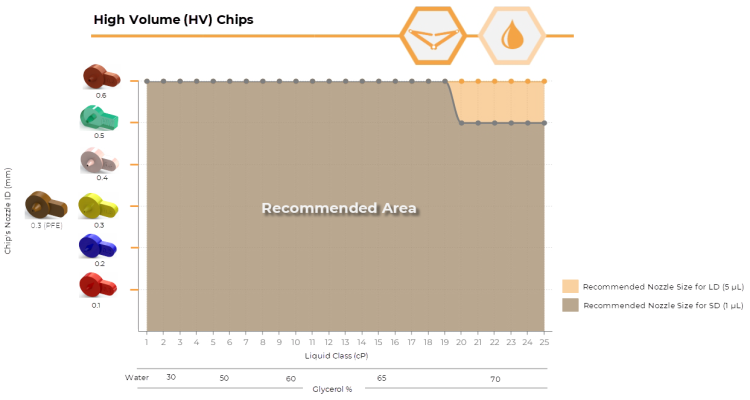

As your reagents’ viscosity might vary from <1 cP (very low) to >25 cP (very high), selecting the correct chip nozzle size and liquid class for your reagents is critical to achieve optimal dispense quality. Selecting the proper nozzle size prevents large hanging drops from building up on the nozzle.

As a general rule, more viscous reagents (glycerol, PEG, etc.) are best dispensed through smaller nozzles and less viscous reagents (alcohols, detergents, surfactants, etc.) are dispensed best through larger nozzles. Small nozzle inner diameter (ID) creates more backpressure, resulting in a higher liquid ejection velocity, whereas larger nozzles cause a "softer" dispense.

Use the following plots to guide your nozzle selection process. All nozzle sizes under the curves have been tested to work for the specified reagent viscosity. Nozzle sizes falling above the shaded area are not recommended. These recommendations were generated using glycerol and will not be definitive for all reagents as fluid properties can vary widely.

MANTIS LV Chip’s Nozzle Size Guide Chart

MANTIS HV Chip’s Nozzle Size Guide Chart

When dispensing with CF chips, larger nozzles result in higher flow rates. The nozzle vs viscosity chart for HV chips is a good reference for CF chips.

For more information on the MANTIS chip’s nozzle size, see MANTIS Chip's Nozzle Kits Catalog.

Related Topics

|

|

| MAOWH-V48R824 |