If you experience inaccurate dispense volumes with MANTIS, there could be a problem with the instrument’s pressure and vacuum regulators or solenoids. To check the regulator and solenoid functionality, you can use the Pneumatic System Check wizard.

Prerequisites:

- You are running MANTIS 5.1 or newer.

To check the pneumatic system functionality:

-

Go to the Tools menu and select Pneumatic System Check.

-

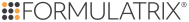

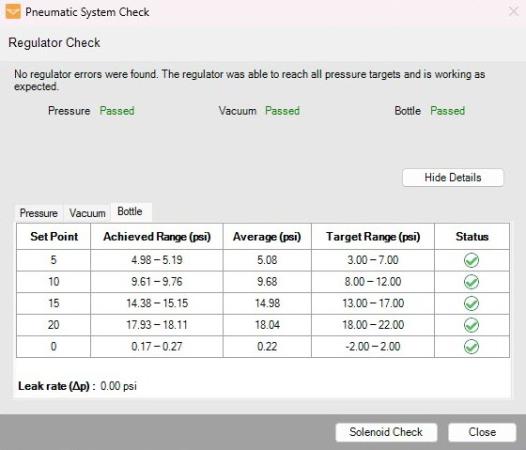

MANTIS first will check the pressure and vacuum regulators’ functionality. The check involves the pressure and vacuum testing generated by the regulators for dispensing with diaphragm chips, and the bottle pressure value used for Continuous Flow dispense.

-

After the check has completed, test results will be automatically generated in the table with the status indicator either passed

or failed

or failed .

.

Chip, Vacuum, and Bottle Values are Within the Expected Range

Regulator Check Failed

-

If there is no regulator error detected, click Solenoid Check to proceed with the solenoid functionality test. Click Close to stop the test and close the wizard.

Note: If any regulator failed or the generated values are outside of the expected range, Retry the test or click Contact Support and Continue to report the issue to the FORMULATRIX support.

-

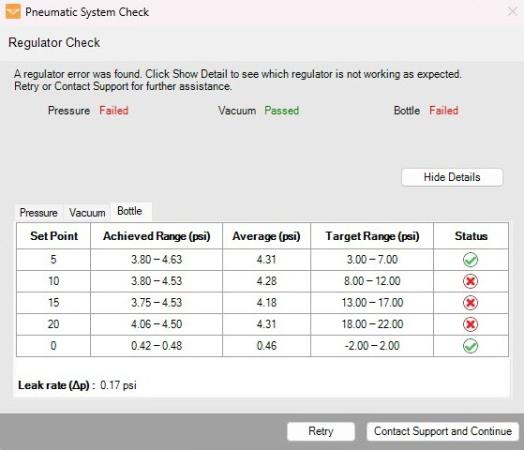

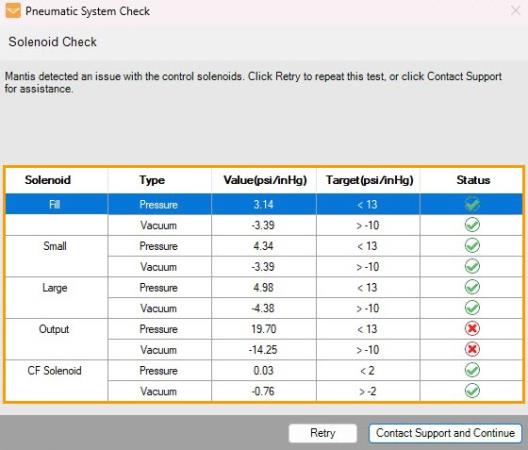

When the Solenoid Check finished, the result will be generated in the table with the passed

or failed

or failed statuses.

statuses.

No Solenoids Are Stuck

MANTIS Detected Stuck Solenoid

Note: If MANTIS detected a stuck solenoid or any of the generated values are outside of the expected range, click Retry to run the solenoid test or Contact Support and Continue to report the issue.

-

Click Close to finish the test and close the wizard.

For more information, see Pneumatic System Check.

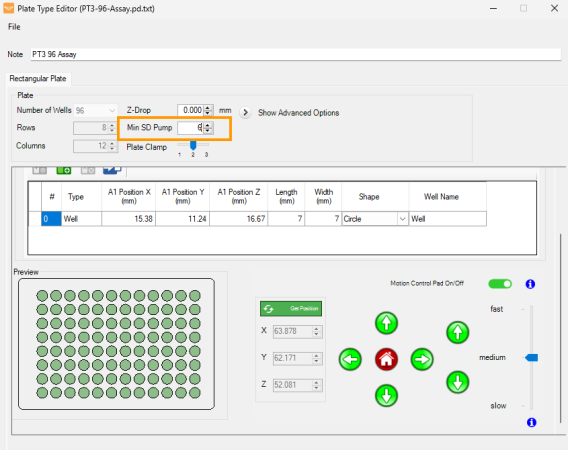

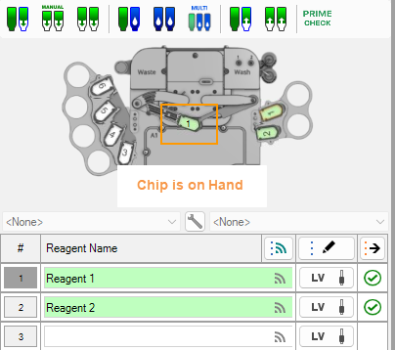

to move the MANTIS hand to the current A1 well location.

to move the MANTIS hand to the current A1 well location.