Lubricating the O-rings¶

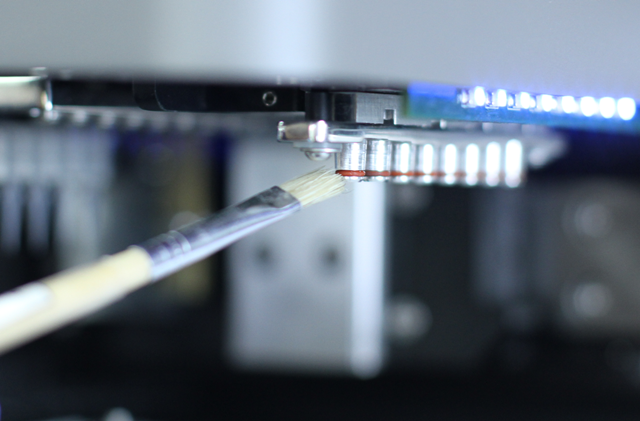

For NT8 V3 hardware only. The NT8 O-ring is a small red or black rubber circle (colors may vary depending on your NT8 series) on the NT8’s plate copy head that create air-tight seals around each of the eight nozzles.

Note

O-rings are only found on the plate copy head; if you did not purchase the Plate Copy option, you do not need to follow these instructions.

If you are noticing an aspirate or dispense volume problem when attempting to copy a plate, you should lubricate the O-rings as part of a troubleshooting effort. Otherwise, the O-rings should be lubricated every six months.

The estimated time required to grease the NT8 O-ring is 3 minutes.

Before you begin, please make sure that there are no High Volume tips attached to the NT8’s plate copy head.

Prerequisites¶

The NT8 is powered off and unplugged.

What You Will Need:¶

A small paint brush (shipped in your accessory kit).

Grease (shipped in your accessory kit).

A deep well block filled about half way with water colored with food dye.

A daughter plate.

A High Volume tip caddy with 8 HV tips.

To Lubricate the O-rings¶

Open the hood to expose the NT8’s head and deck.

Using the paintbrush, lightly but evenly apply grease to the front and back of each of the eight O-rings on the NT8’s plate copy head.

When you are finished, power-on the NT8 and continue with Running a Plate Copy Test.

Related Topics