Subcontract Transactions

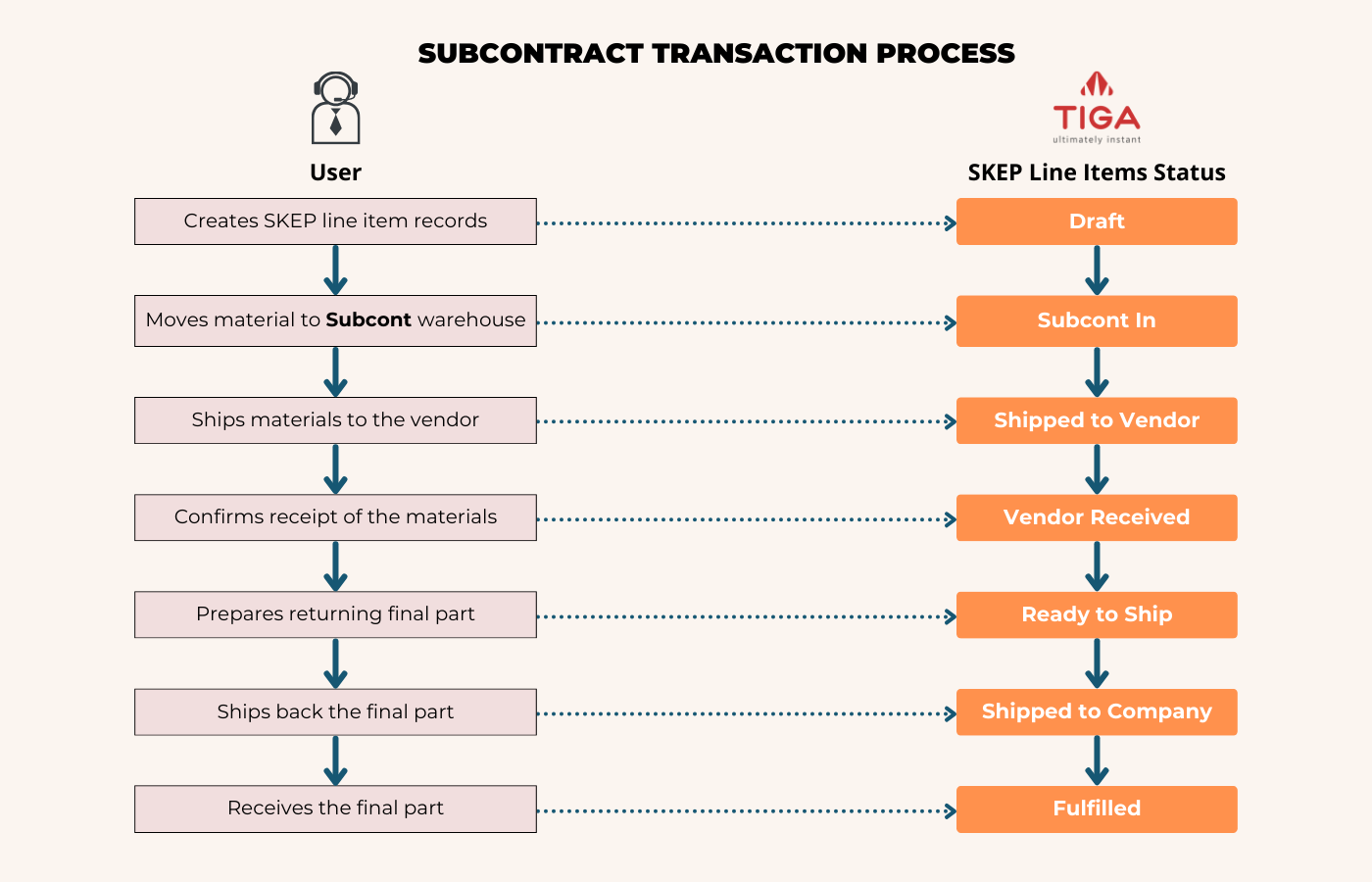

After the SKEP approval, the subcontracting process moves to the transaction phase. This phase ensures that materials are transferred from the company to Formulatrix Indonesia (FOI) as the vendor, processed, and then returned as final parts to the company warehouse. The main goal of subcontract transactions is to maintain accurate tracking of material movements throughout the outsourcing process.

Subcontract Transactions Process

The transaction process consists of three main stages, each involving a specific transaction that updates the status in the SKEP Line Items table.

Subcontract Transaction Process

Please check the Status column in the SKEP Line Items table to monitor the progress of the subcontract.

Status |

Description |

|---|---|

Draft |

Initial status when creating the SKEP line item record, but not yet processed. |

Subcont In |

Materials are moved to the Subcont warehouse and are ready for shipment to the vendor. The status is automatically updated after creating the Subcont In transaction and confirming the line items. |

Shipped to Vendor |

Materials are shipped from the Subcont warehouse to the vendor for processing. TIGA automatically updates the status after creating the Shipment Out transaction and confirming the line item. |

Vendor Received |

The vendor confirms receipt of the materials, and the secretary updates the status manually. |

Ready to Ship |

Final parts have been processed by the vendor and are ready to be shipped back to the company. The status is automatically updated after creating the Initial Issued In transaction and confirming the line item. |

Shipped to Company |

Final parts are shipped from the vendor to the company’s warehouse. TIGA automatically updates the status after creating a Shipment Out transaction and confirming the line item. |

Fulfilled |

The final parts have arrived at the company’s warehouse, and the subcontracting process is complete. The status is automatically updated after creating the Shipment In transaction and confirming the line item. |

Important

Once all subcontracted tasks are completed and all final parts are completely fulfilled, the user can update the SKEP list status to Closed. However, if the process needs to be terminated before completion for any reason, the Accounting team can force close the SKEP list to prevent further transactions.

Creating SKEP Line Items and Breakdown

Once the SKEP Number is obtained from the customs, the secretary creates SKEP line items and breakdown records as requested. These records define when the process starts, which final parts will be used, and the quantities for each subcontract phase.

Prerequisites:

An Approved or Open to Buy subcontract work order (WO) exists.

SKEP list record is Open and not marked as Locked.

To create skep line items and breakdown:

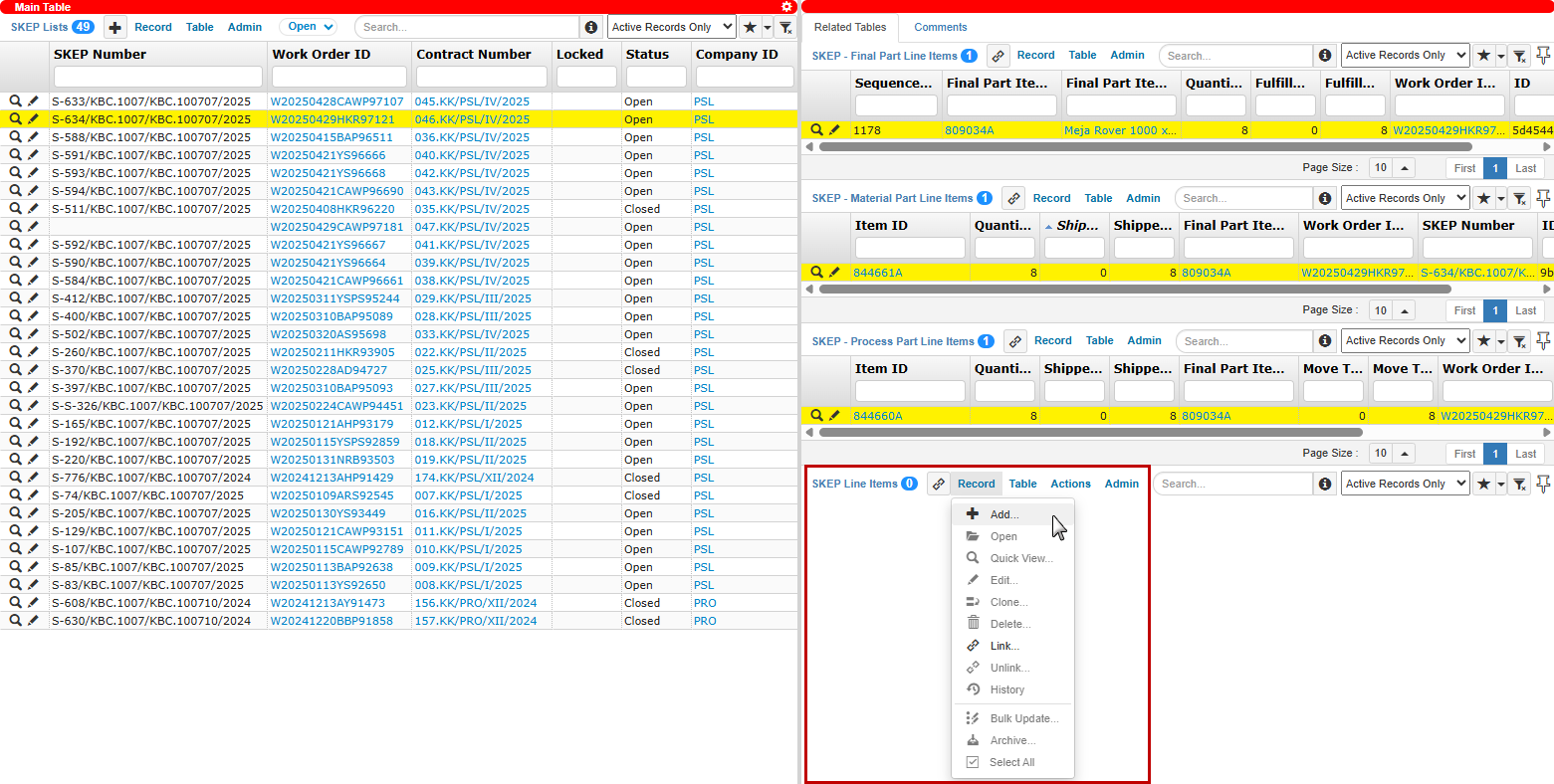

Open the SKEP Lists table and access the SKEP Line Items/Related Tables to manage the subcontracting process based on the existing SKEP number.

Click Add and enter the Date, marking the initiation of the subcontract process.

Note

The system automatically creates a record with Draft status and process 1, indicating the first processing batch.

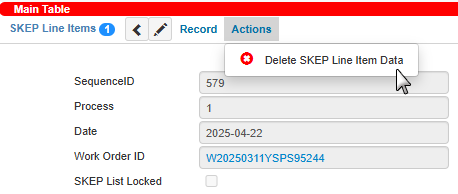

Use Delete SKEP Line Item Data action if you want to delete the SKEP line items record only if the SKEP list record is Open and not marked as Locked.

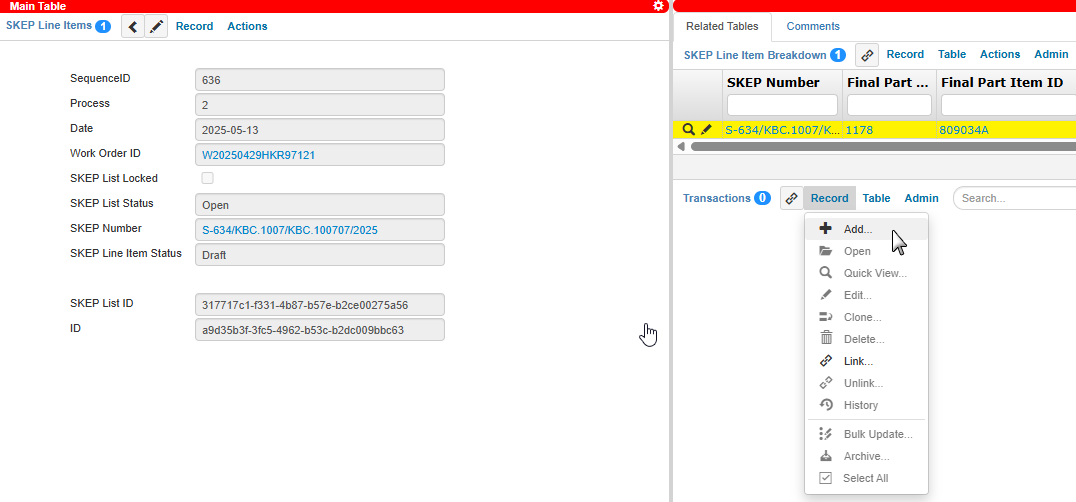

Double-click the newly created Draft SKEP line item to open.

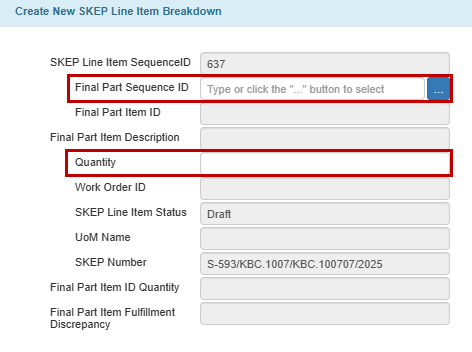

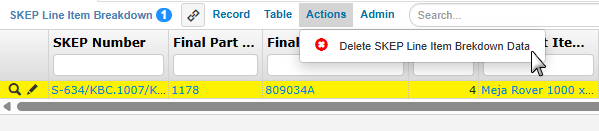

Add a new record to the SKEP Line Item Breakdown/Related Table.

Note

Specify the final part and quantity to be processed in this batch. Include only the relevant items for this subcontracting phase and do not exceed the Final Part Item ID Quantity or Final Part Item ID Quantity Discrepancy fields.

Post Condition:

The SKEP line item breakdown record is created, containing the list of final parts and their quantities to be processed.

Moving Materials to the Subcont Warehouse

Once a Draft SKEP line item and its breakdown record are created, the secretary begins by opening a record from the SKEP Line Item table and accessing the Transactions/Related Table to create a Subcont In transaction.

Note

Select the warehouse with the Subcont category that matches the work order company. Choose either Promanufacture Salatiga - Subcont or Promanufacture - Subcont warehouse in the Warehouse field to specify the destination. Read more about warehouse categories.

Add a Transaction Record

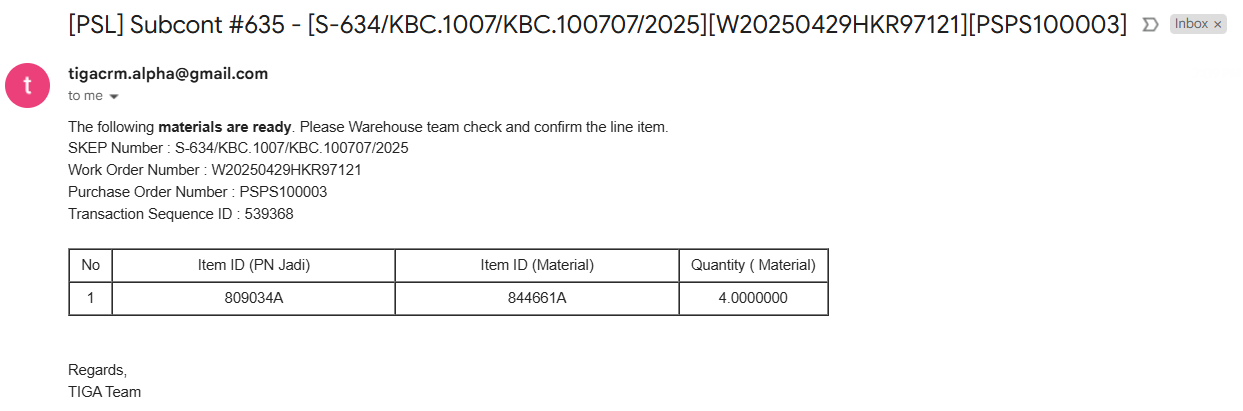

After creating the transaction, TIGA automatically:

Generates the transaction line item (TLI) records, which contain items from the SKEP - Material Part Line Items table, representing the materials to be moved.

Sends a notification email to relevant stakeholders, including the requester, WO assignee, Warehouse, Exim, QC, Purchasing, “Subcontract FOI Admin”, and “FOI Subcont” (TIGA team), confirming that the materials are ready to be moved to the Subcont warehouse.

The Warehouse team then confirms the transaction line item to complete the process. Upon confirmation, TIGA automatically:

Updates the SKEP line item status to Subcont In.

Changes the Subcont In transaction status to Closed.

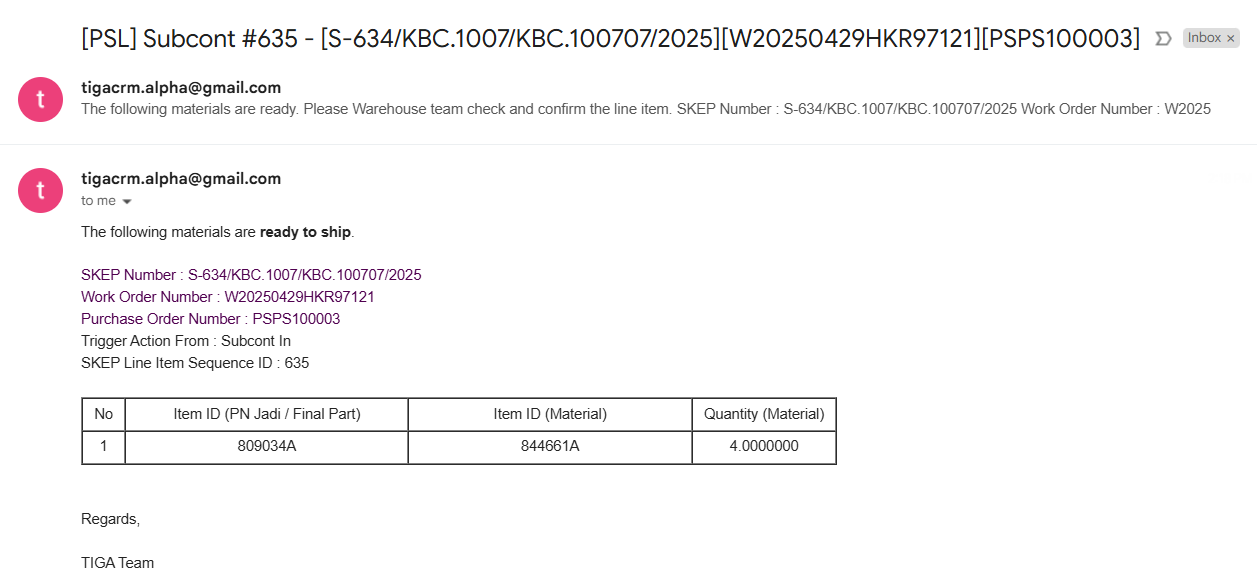

Sends a follow-up email notification to the same stakeholders, indicating that the materials are ready to be shipped.

Shipping to the Vendor

After preparing the materials, the Exim team ships them from the Subcont warehouse to FOI to initiate the processing.

Prerequisites:

SKEP line item status is Subcont In.

You are part of the Exim team.

To create a shipment out transaction:

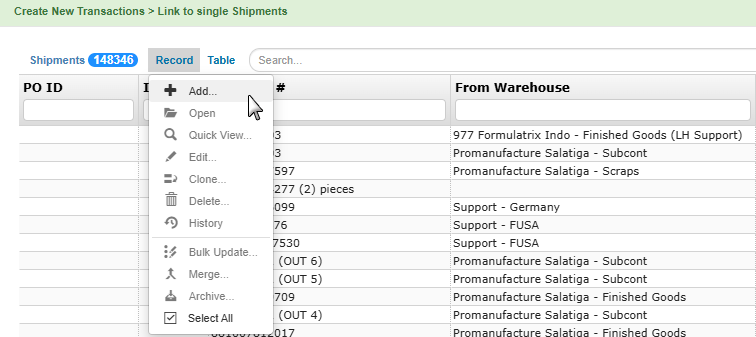

Open the SKEP Line Items/Related Tables and access Transactions/Related Tables to manage the movement of materials.

Click Add to create Shipment Out transaction, and fill in the Warehouse field and the Shipment section.

Note

Select the warehouse with the Subcont category that matches the work order company. Choose either Promanufacture Salatiga - Subcont or Promanufacture - Subcont warehouse in the Warehouse field.

Tip

Since this transaction type requires a shipment record to be linked in the Shipment section, you can either create the record beforehand in the Shipments table or during the creation of the transaction.

Note

TIGA automatically generates shipment line items and the transaction line item (TLI) records, which contain items from the SKEP - Material Part Line Items table, representing the materials being moved to FOI.

Post Conditions:

TIGA automatically:

Updates the SKEP line item status to Shipped to Vendor.

Updates the Shipment Out transaction status to Closed.

Updates the quantity in the Shipped and Shipped Discrepancy fields of the SKEP - Material Part Line Items table.

Sends email notification to the requester, WO assignee, Warehouse, Exim, QC, Purchasing, “Subcontract FOI Admin”, and “FOI Subcont” (TIGA team), confirming that the materials have been shipped to FOI.

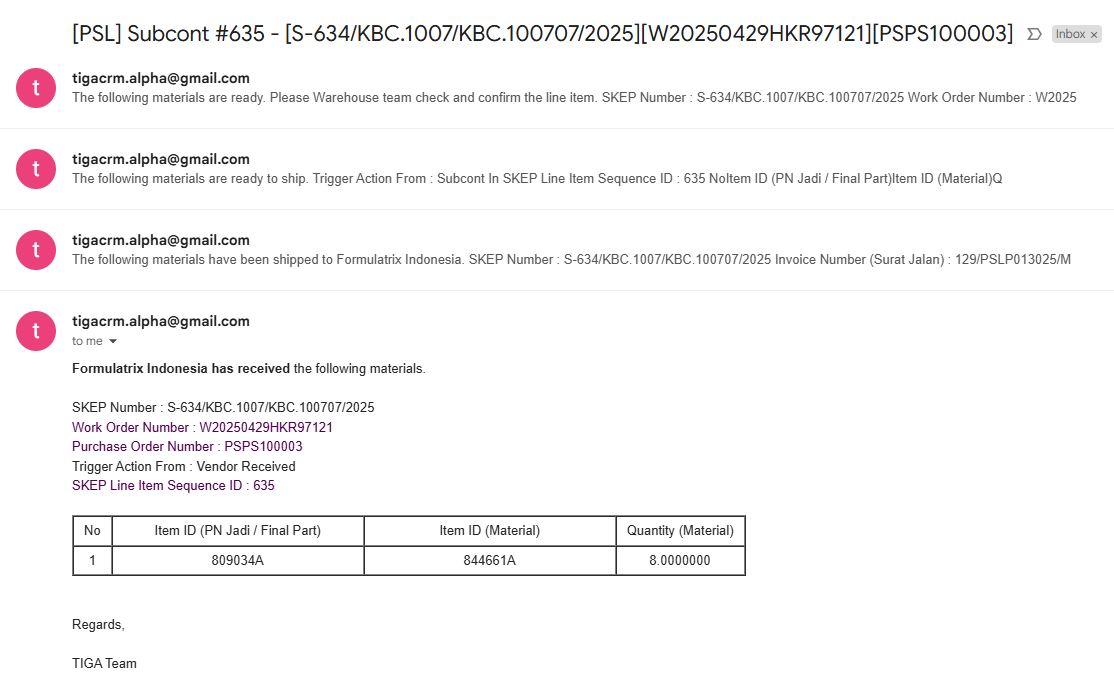

Vendor Receiving and Processing

Once the shipment arrives at the vendor’s site, the vendor informs the secretary to manually update the SKEP line item status to Vendor Received. An email notification is then sent to the requester, WO assignee, Warehouse, Exim, QC, Purchasing, “Subcontract FOI Admin”, and “FOI Subcont” (TIGA team).

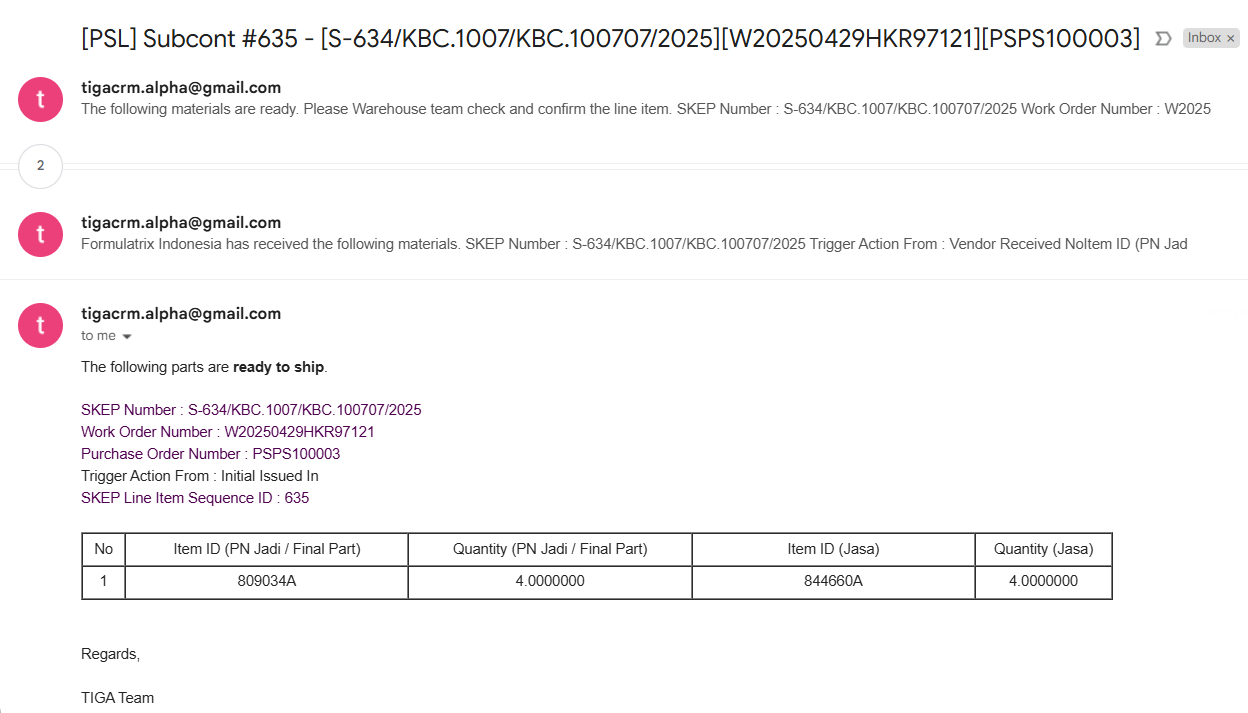

Vendor Received Materials Email Notification

Upon completion of production tasks, such as coating or welding, the vendor informs the Warehouse team that the final parts are ready. The Warehouse team then creates an Initial Issued In transaction.

Prerequisites:

SKEP line item status is Vendor Received.

You are part of the Warehouse team.

To create an initial issued in transaction:

Open the SKEP Line Items/Related Tables and access Transactions/Related Tables.

Click Add to create Initial Issued In transaction and select 977 Formulatrix Indo - Finished Goods (LH Support) as the warehouse in the Warehouse field.

Note

TIGA automatically generates the transaction line item (TLI) records, which contain items from the SKEP - Process Part Line Items table, representing the specific processing tasks performed by the vendor.

Post Conditions:

TIGA automatically:

Updates the SKEP line item status to Ready to Ship.

Updates the Initial Issued In transaction status to Closed.

Updates the quantity in the Move to Finished Goods and Move to Finished Goods Discrepancy fields of the SKEP - Process Part Line Items table.

Sends email notification to the requester, WO assignee, Warehouse, Exim, QC, Purchasing, “Subcontract FOI Admin”, and “FOI Subcont” (TIGA team), confirming that the finished goods are ready for return to the company.

Returning Final Parts to the Company

After the final parts are ready, they are shipped back from the Finished Goods warehouse to the company’s warehouse.

Prerequisites:

SKEP line item status is Ready to Ship.

You are part of the Exim team.

To create a shipment out transaction:

Open the SKEP Line Items/Related Tables and access Transactions/Related Tables.

Click Add to create Shipment Out transaction and fill in the Warehouse field and Shipment section.

Note

Select 977 Formulatrix Indo - Finished Goods (LH Support) warehouse in the Warehouse field.

Tip

Since this transaction type requires a shipment record to be linked in the Shipment section, you can either create the record beforehand in the Shipments table or during the creation of the transaction.

Note

TIGA automatically generates the transaction line item (TLI) records, which contain items from the SKEP - Process Part Line Items table, representing the specific processing tasks performed by the vendor.

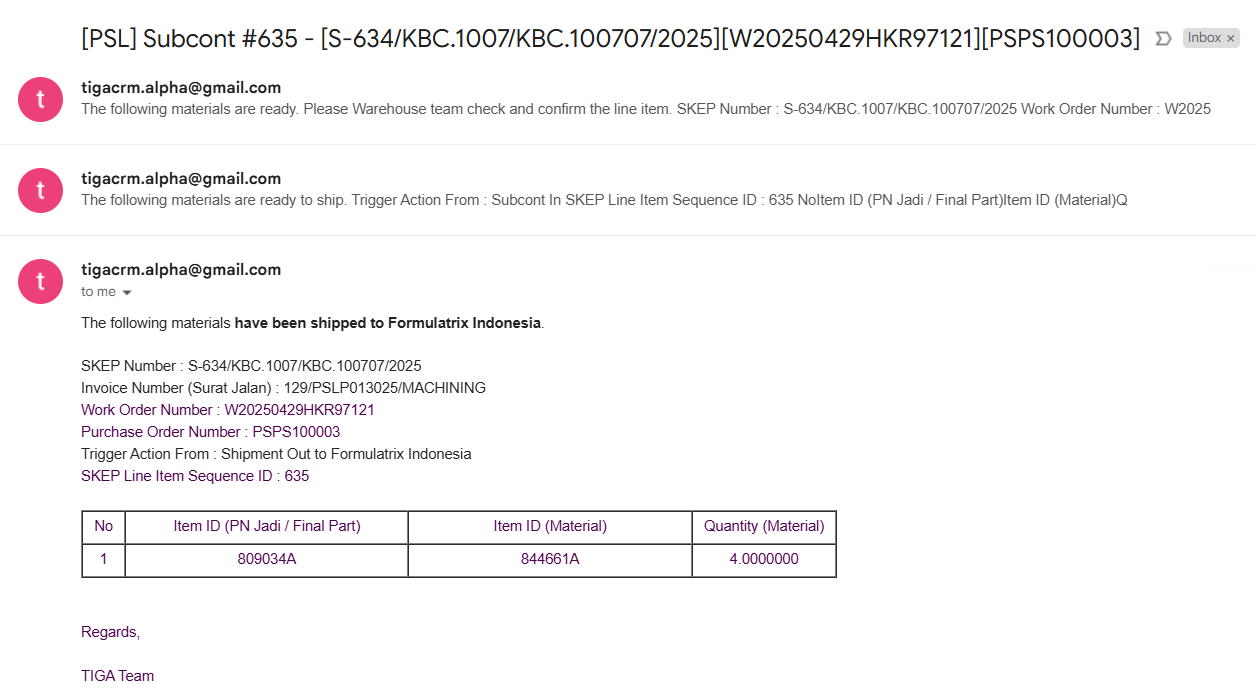

Post Conditions:

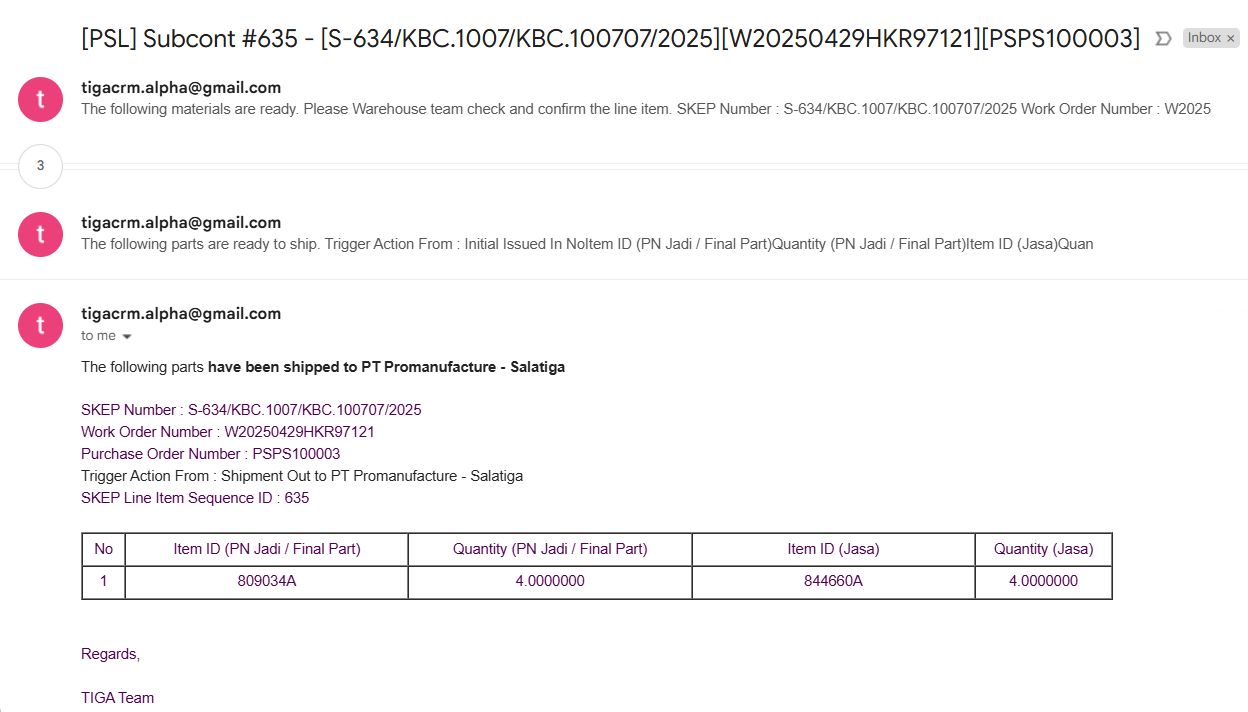

TIGA automatically:

Updates the SKEP line item status to Shipped to Company.

Updates the Shipment Out transaction status to Closed.

Updates the quantity in the Shipped and Shipped Discrepancy fields of the SKEP - Process Part Line Items table.

Sends email notification to the company to the requester, WO assignee, Warehouse, Exim, QC, Purchasing, “Subcontract FOI Admin”, and “FOI Subcont” (TIGA team), confirming that the processed goods have been shipped.

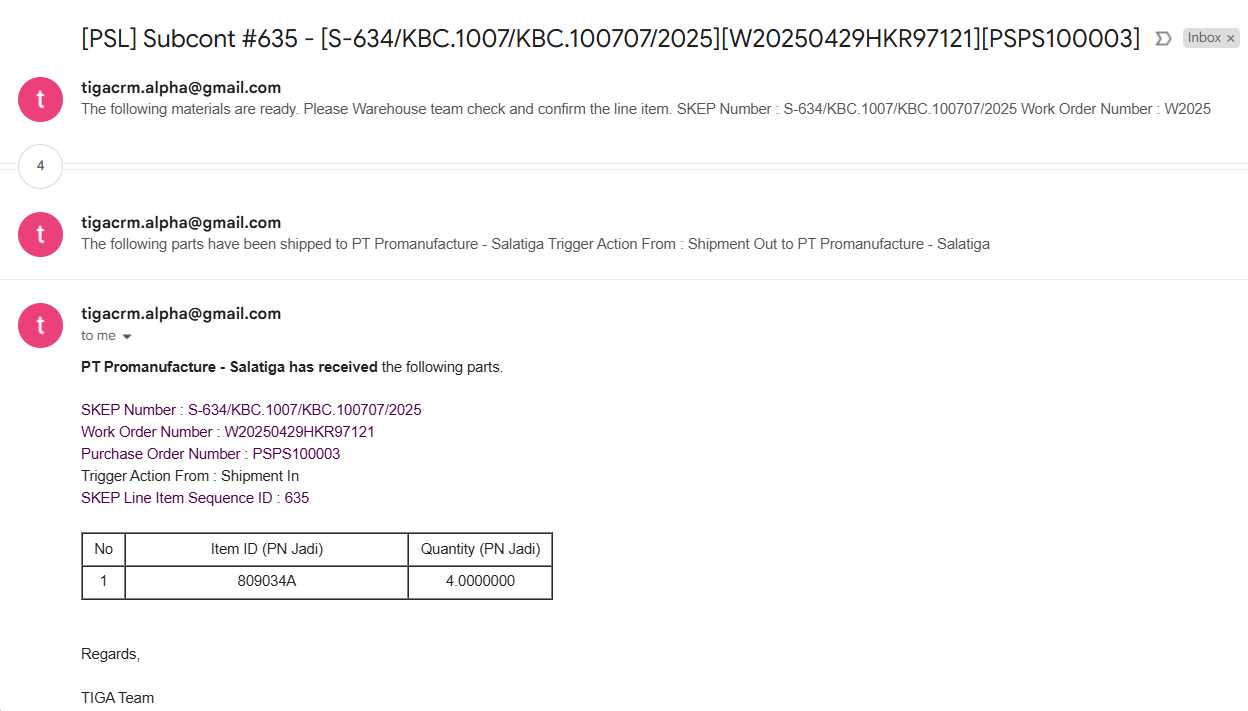

Receiving Final Parts

When the final parts arrive at the company warehouse, the Warehouse team shall confirm receipt to complete the subcontracting process.

Prerequisites:

SKEP line item status is Shipped to Company.

You are part of the Warehouse team.

The purchase order (PO) linked to the subcontract work order (WO) has Sent status.

Note

Once the PO is marked as Sent, TIGA automatically sends an email to Warehouse and Purchasing and creates a shipment record.

The shipment record is linked to shipment document.

To create a shipment in transaction:

Open the SKEP Line Items/Related Tables and access Transactions/Related Tables.

Click Add to create a Shipment In transaction and fill in the Warehouse field, Purchase Order, and Shipment section.

Note

Select either Promanufacture Salatiga or Promanufacture warehouse in the Warehouse field.

Once created, TIGA automatically generates the transaction line item (TLI) records, which contain items from the SKEP - Final Part Line Items table, representing the completed items returned to the company.

Post Conditions:

TIGA automatically:

Updates the SKEP line item status to Fulfilled.

Updates the Shipment In transaction status to Closed.

Updates the quantity in the Fulfillment and Fulfillment Discrepancy fields of the SKEP - Final Part Line Items table.

Creates the shipment line item and vendor bill records.

Sends email notification to the requester, WO assignee, Warehouse, Exim, QC, Purchasing, “Subcontract FOI Admin”, and “FOI Subcont” (TIGA team), confirming the shipment of processed goods to the company.

Related Topics: