Ready to Manufacture (RTM)

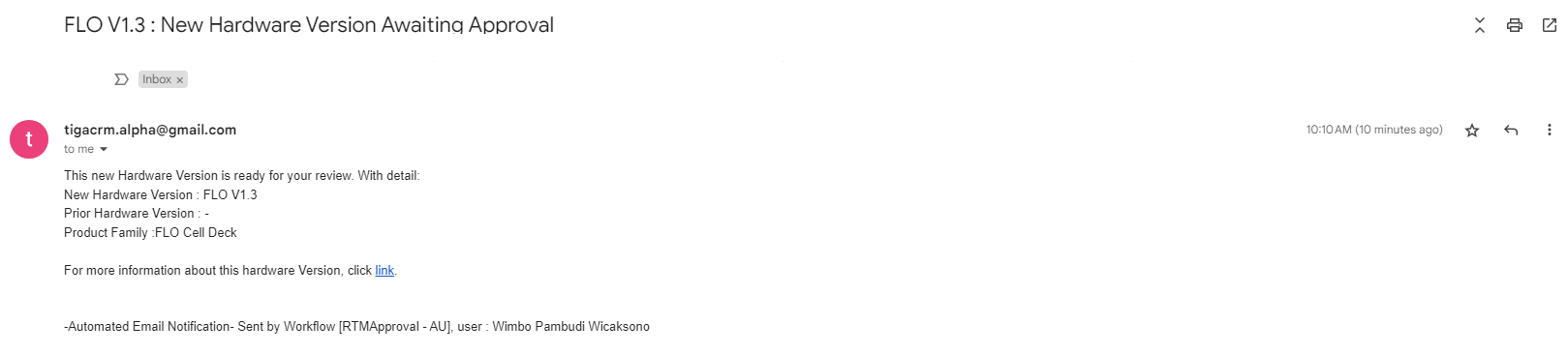

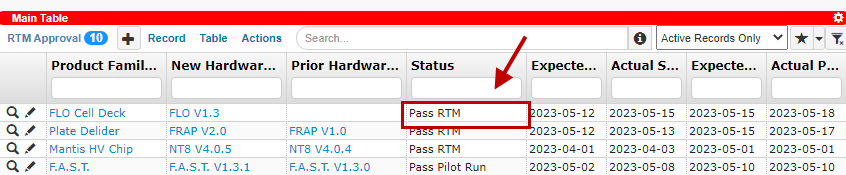

Launching a product to the market requires thorough preparation, and the Ready to Manufacture (RTM) phase is an essential part of this process. RTM ensures the proper transfer of product knowledge from the engineers to the production division. TIGA employs the RTM Approval table to document all RTM processes and enable progress monitoring by other users.

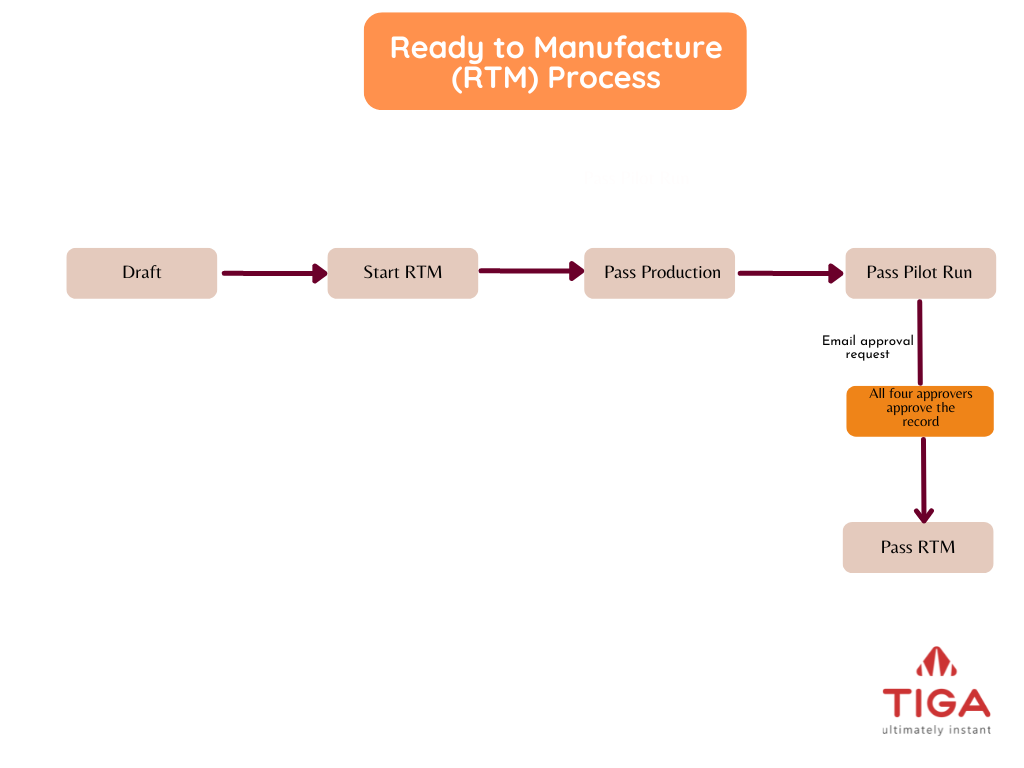

RTM Process

The RTM goal is for the production division to create a new product or product version. The actual process mainly involves the production division and process engineers (PE), but the “NPI” (New Product Introduction) group is responsible for documenting the processes in TIGA. The group will create the record in the RTM Approval table and maintain the RTM process by editing the Status and inputting its Actual Date. After all four approvers approve the Pass Pilot Run record, TIGA will automatically update the status to Pass RTM and fill in the Pass RTM Actual Date field.

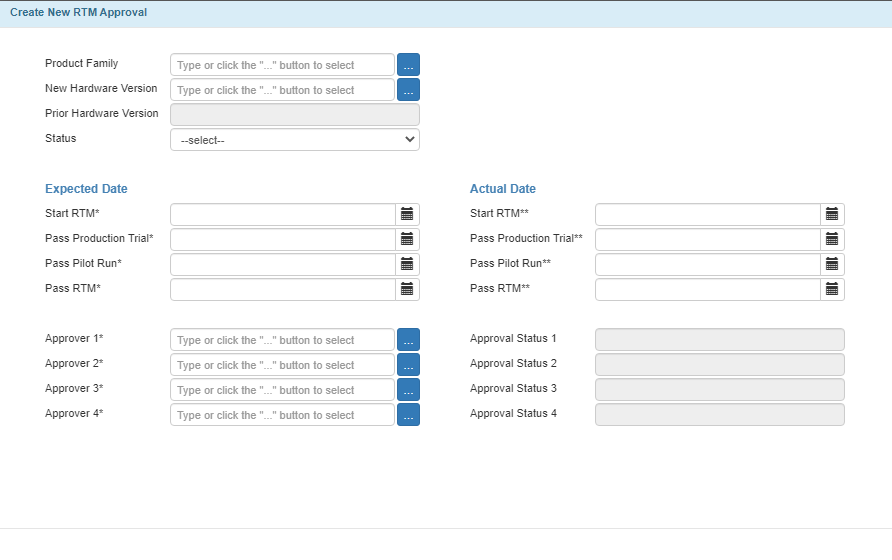

Create New RTM Approval Window

Note

You can’t skip a status. Adjust the status sequentially and input its actual date before updating the record.

Read the description of each status below.

Status Name |

Description |

|---|---|

Draft |

It is the status of a newly created record. Tip

|

Start RTM |

This status marks the start of the RTM process. |

Pass Production Trial |

The process engineers (PE) iterate production trials to create the product and transfer the knowledge to the production division. |

Pass Pilot Run |

The production division successfully creates the product and meets the targeted production without PE’s assistance. |

Pass RTM |

All approvers approve the Pass Pilot Run record. |

Approving a Pass Pilot Run Record:

Related Topics: