Mold Trial

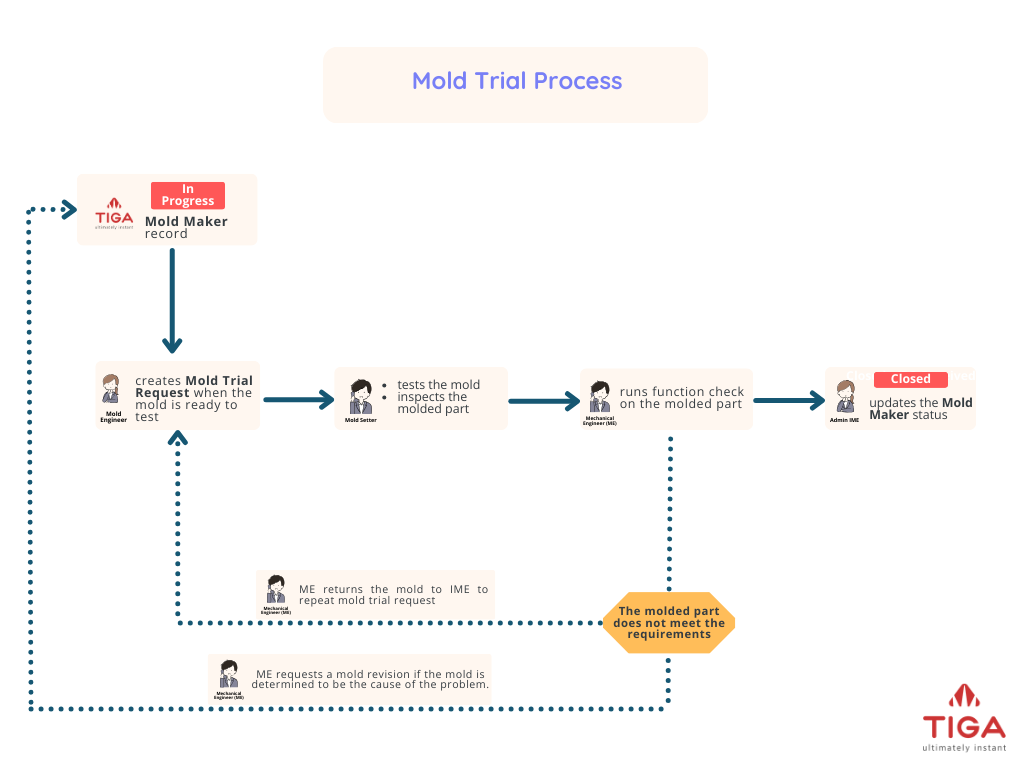

The mold trial process starts after the mold assembly process finishes and when the mold maker’s status is In Progress. It involves testing the mold under real operating conditions to confirm that it meets the requirements. Insights from the mold trial process are crucial for producing a mold that works. The mold engineer, mold setter, process engineer, and mechanical engineer work together to identify potential issues during the mold trial.

Mold Trial Process

Mold Trial Request

A mold engineer creates a Mold Trial Request in TIGA to start the mold trial process.

To create a mold trial request:

Open the Mold Design table and choose a record.

Create a new record in the Mold Trial/Related Tables.

Note

When you create a Mold Trial record, TIGA will autofill some information from the linked Mold Design record.

Important

Coordinate with the PIC listed in the PPIC field to schedule the use of an injection machine before completing the Date field.

If you have more than one trial attempt, create a new Mold Trial Request record and fill out the Trial Number field in chronological order.

Post Condition

Upon request creation, TIGA sends a notification email to the mold design requester (mechanical engineer/ME), ME manager, process engineer, mold setter, PPIC, IME manager and assistant manager, and injection manager.

Mold Trial Execution

Once the request is submitted, a mold setter—an IME responsible for the mold trial process —runs the actual production trial, as follows.

Test the mold in the injection machine.

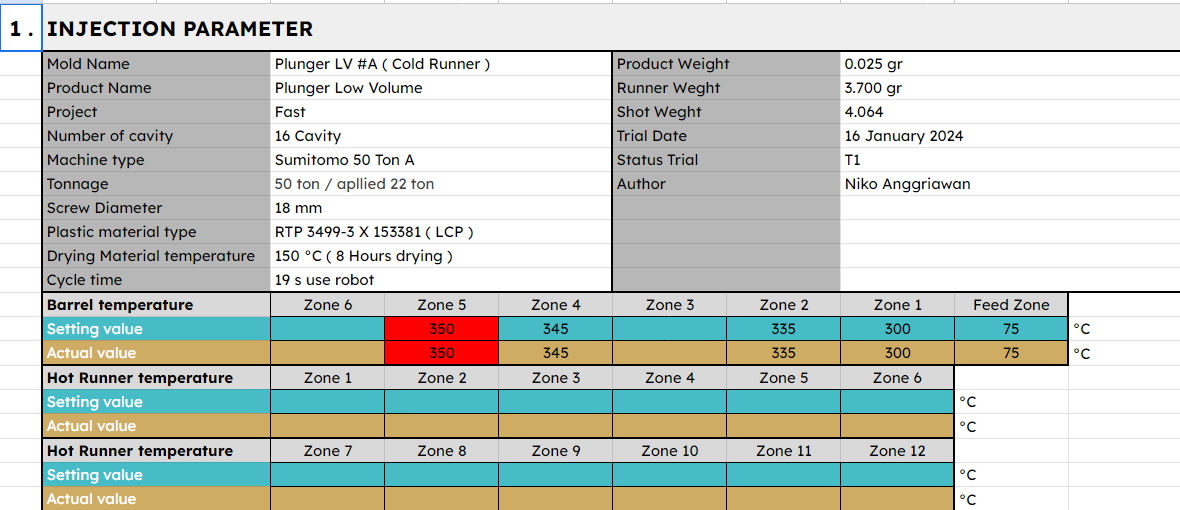

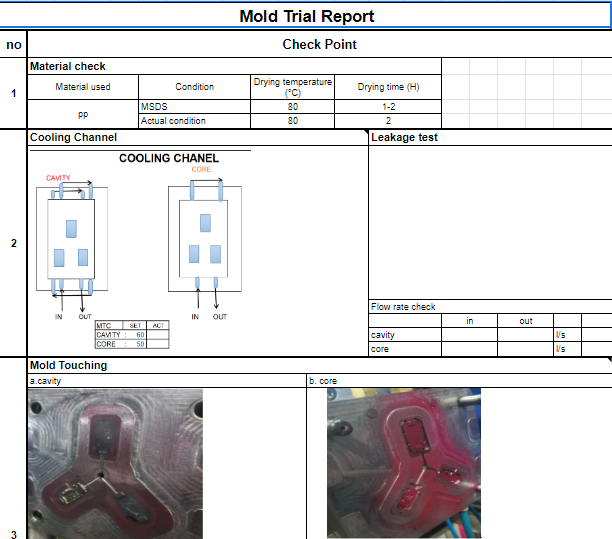

In this process, the mold setter checks the mold’s mechanism and finds the optimum parameter to produce a good molded part. During the testing, the mold setter records the data on the trial report and injection parameter form.

Injection Parameter Form

Run visual and dimension checks on the molded part.

In this process, the mold setter inspects the molded part and reports the findings during the internal evaluation meeting.

Conduct internal evaluation meetings.

The mold setter arranges an evaluation meeting with the mold engineer to make sure the molded part fulfills the mechanical engineer’s requirements. The meeting discussions are recorded in the evaluation meeting journal. If the requirement is not met, the IME will repeat the trials to find the best parameter. Otherwise, the IME may need to modify the mold.

Evaluation Meeting Journal Example

The mold setter keeps all records of all the above processes in a spreadsheet and attaches the spreadsheet link in the Attachment/Related Tables in the Mold Trial table.

Final Decision

After the mold engineer finishes the mold trial process,

The mold design requester—the mechanical engineer (ME)—runs a function check and completes the ME QC record based on the Mold Trial process.

The IME administrator updates the Mold Maker status to Closed after the mechanical engineer confirms that the mold meets their requirements.

If the molded part does not meet the requirements, the ME will either send the mold back to repeat the mold trial process or create a new Mold Maker record to request a new mold.